Use search to quickly locate question answers – open up a search box (ctrl+f), then enter a keyword from the question to navigate you to those terms in the course material

Introduction

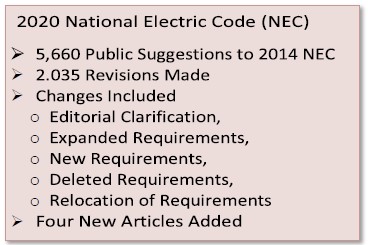

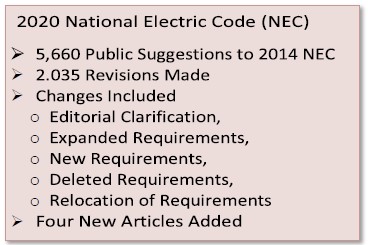

Every three years, the National Electrical Code® (NEC®) is revised and expanded. Initially the NFPA® received 3,730 public suggestions for changes, which resulted in 1,400 first revisions. There were 1,930 public comments submitted in response to these 1,400 first revisions, resulting in 635 second revisions. Changes included editorial clarification, expanded requirements, new requirements, deleted requirements, and the relocation of other requirements. Nine new articles were proposed, and four new articles were added to the 2020 NEC. With the fast pace of technology, it’s more important than ever for anyone participating in the electrical industry to get up to speed with all the changes.

Every three years, the National Electrical Code® (NEC®) is revised and expanded. Initially the NFPA® received 3,730 public suggestions for changes, which resulted in 1,400 first revisions. There were 1,930 public comments submitted in response to these 1,400 first revisions, resulting in 635 second revisions. Changes included editorial clarification, expanded requirements, new requirements, deleted requirements, and the relocation of other requirements. Nine new articles were proposed, and four new articles were added to the 2020 NEC. With the fast pace of technology, it’s more important than ever for anyone participating in the electrical industry to get up to speed with all the changes.

What to Expect

In this course the student will be presented an overview of the most significant changes found in the 2020 NEC. This is part 1 of a series of courses covering the changes and will progress through each chapter and its articles presenting the many important changes. The changes will be underlined for easy recognition and a short synopsis of the reason for the change is presented as well.

Note: Highlights are New Text, Strikethrough are Deleted Text

Introduction: Article 9090.2 (A)(5) Scope

Reason for Change: Revision clarifies that the NEC covers installations supplying shore power to ships and watercraft, including monitoring of leakage current.

90.2(A) Scope

90.2(A) Scope

(A) Covered. This Code covers the installation and removal of electrical conductors, equipment, and raceways; signaling and communications conductors, equipment, and raceways; and optical fiber cables for the following:

(1) Public and private premises, including buildings, structures, mobile homes, recreational

vehicles, and floating buildings

(2) Yards, lots, parking lots, carnivals, and industrial substations

(3) Installations of conductors and equipment that connect to the supply of electricity

(4) Installations used by the electric utility, such as office buildings, warehouses, garages, machine shops, and recreational buildings, that are not an integral part of a generating plant, substation, or control center

(5) Installations supplying shore power to ships and watercraft in marinas and boatyards, including monitoring of leakage current

(6) Installations used to export electric power from vehicles to premises wiring or for bidirectional current flow

Chapter 1. General

Article 100 — Definitions

Accessible (as applied to equipment)Reason for Change: The definition of Accessible (as applied to equipment) was revised for clarity and usability.

Accessible (as applied to equipment).

Accessible (as applied to equipment). Admitting close approach; not guarded by locked doors, elevation, or other effective means. C

apable of being reached for operation, renewal, and inspection. (CMP-1)

Reason for Change: The definition of a Supply-Side Bonding Jumper was relocated from 250.2 to Article 100.

Bonding Jumper, Supply-Side.

Bonding Jumper, Supply-Side. A conductor installed on the supply side of a service or within a service equipment enclosure(s), or for a separately derived system, that ensures the required electrical conductivity between metal parts required to be electrically connected. (CMP-5)

Reason for Change: A new definition for a “Dormitory Unit” was introduced at Article 100.

Dormitory Unit.

Dormitory Unit. A building or a space in a building in which group sleeping accommodations are provided for more than 16 persons who are not members of the same family in one room, or a series of closely associated rooms, under joint occupancy and single management, with or without meals, but without individual cooking facilities. (CMP 2)

Reason for Change: The definition for “Equipotential Plane was relocated from 682.2 to Article 100.

Equipotential Plane

Equipotential Plane.

An area where wire mesh or other conductive elements are on, embedded in, or placed under the walk surface within 75 mm (3 in.), bonded to all metal structures and fixed nonelectrical equipment that may become energized, and connected to the electrical grounding system to prevent a difference in voltage from developing within the plane.

Accessible conductive parts bonded together to reduce voltage gradients in a designated area. (CMP-17)

Reason for Change: Two new definitions for “Fault Current” and “Fault Current, Available (Available Fault Current)” were added to Article 100. A new Informational- Note Figure 100.1 was also added.

Fault Current.

Fault Current. The current delivered at a point on the system during a short-circuit condition. (CMP-10)

Fault Current, Available (Available Fault Current). The largest amount of current capable of being delivered at a point on the system during a short-circuit condition. (CMP-10)

Informational Note: A short-circuit can occur during abnormal conditions such as a fault between circuit conductors or a ground fault. See Informational Note Figure 100.1.

Figure Informational Note Figure 100.1 Available Fault Current.

(see illustration above and NEC Code text for figure)

Reason for Change: A new definition for “Free Air (as applied to conductors)” was added to Article 100.

Free Air (as applied to conductors).

Free Air (as applied to conductors). Open or ventilated environment that allows for heat dissipation and air flow around an installed conductor. (CMP-6)(CMP-1)

Reason for Change: A new Informational note was added to the definition of a “Grounded Conductor.” The new informational note is intended to clarify that an equipment grounding conductor is not subject to the identification and connection rules of a grounded conductor.

Grounded Conductor.

Grounded Conductor. A system or circuit conductor that is intentionally grounded. (CMP-5)

Informational Note: Although an equipment grounding conductor is grounded, it is not considered a grounded conductor.Reason for Change: A new definition for “Habitable Room” was added to Article 100.

Habitable Room.

Habitable Room. A room in a building for living, sleeping, eating, or cooking, but excluding bathrooms, toilet rooms, closets, hallways, storage or utility spaces, and similar areas. (CMP-2)

Reason for Change: A new definition for “Island Mode” primarily related to microgrid systems and stand-alone systems was added to Article 100.

Island Mode.

Island Mode.

The operational mode for standalone power production equipment or an isolated microgrid, or for a multimode inverter or an interconnected microgrid that is disconnected from an electric power production and distribution network or other primary power source. (CMP-4)

Informational Note: Isolated microgrids are distinguished from interconnected microgrids, which are addressed in Article 705.

Reason for Change: New Informational Note added explaining that even though a section of the NEC may require a product to be labeled, it is common practice to have the label, symbol, or other identifying mark applied to the smallest unit container in which the product is packaged.

Labeled.

Labeled. Equipment or materials to which has been attached a label, symbol, or other identifying mark of an organization that is acceptable to the authority having jurisdiction and concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the manufacturer indicates compliance with appropriate standards or performance in a specified manner. (CMP-1)

Informational Note: If a listed product is of such a size, shape, material, or surface texture that it is not possible to apply legibly the complete label to the product, the complete label may appear on the smallest unit container in which the product is packaged. (CMP-1)

Reason for Change: A new definition for “Reconditioned” was added to Article 100 and an informational note added to indicate that the term reconditioned is frequently referred to as rebuilt, refurbished, or remanufactured.

Reconditioned.

Reconditioned.

Electromechanical systems, equipment, apparatus, or components that are restored to operating conditions. This process differs from normal servicing of equipment that remains within a facility, or replacement of listed equipment on a one-to-one basis. (CMP-10)

Informational Note: The term reconditioned is frequently referred to as rebuilt, refurbished, or remanufactured.Article 110 – Requirements for Electrical Installations

110.3(B) Examination, Identification, Installation, Use, and Listing (Product Certification) of EquipmentReason for Change: Listing requirements were modified for clarity and usability to address equipment that is listed, labeled, or both.

110.3 Examination, Identification, Installation, Use, and Listing (Product Certification) of Equipment.

110.3 Examination, Identification, Installation, Use, and Listing (Product Certification) of Equipment. (B) Installation and Use.

Listed or labeled equipment Equipment that is listed, labeled, or both shall be installed and used in accordance with any instructions included in the listing or labeling.

Reason for Change: Redundant requirements for “Mechanical Execution of Work” for communication cables and conductors in Chapter 7 and 8 were relocated to Article 110.

110.12 Mechanical Execution of Work.

110.12 Mechanical Execution of Work. Electrical equipment shall be installed in a neat and workmanlike manner.

(C) Cables and Conductors. Cables and conductors installed exposed on the surfaces of ceilings and sidewalls shall be supported by the building structure in such a manner that the cables and conductors will not be damaged by normal building use. Such cables and conductors shall be secured by hardware including straps, staples, cable ties, hangers, or similar fittings designed and installed so as not to damage the cable. The installation shall also conform with 300.4 and 300.11. Nonmetallic cable ties and other nonmetallic cable accessories used to secure and support cables in other spaces used for environmental air (plenums) shall be listed as having low smoke and heat release properties.

Informational Note No. 1: Accepted industry practices are described in ANSI/ NECA/FOA 301-2009, Standard for Installing and Testing Fiber Optic Cables, and other ANSI-approved installation standards.

Informational Note No. 2: See 4.3.11.2.6.5 and 4.3.11.5.5.6 of NFPA 90A-2018, Standard for the Installation of Air-Conditioning and Ventilating Systems, for discrete combustible components installed in accordance with 300.22(C).

Informational Note No. 3: Paint, plaster, cleaners, abrasives, corrosive residues, or other contaminants may result in an undetermined alteration of optical fiber cable properties.

Reason for Change: Revisions occurred to the terminal connection torque rules and three new Informational Notes were added.

110.14 Electrical Connections.

110.14 Electrical Connections. (D) Installation

Terminal Connection Torque. Where a tightening torque is indicated as a numeric value on equipment or in installation instructions provided by the manufacturer, a calibrated torque tool shall be used to achieve the indicated torque value, unless the equipment manufacturer has provided installation instructions for an alternative method of achieving the required torque.

Tightening torque values for terminal connections shall be as indicated on equipment or in installation instructions provided by the manufacturer. An approved means shall be used to achieve the indicated torque value. Informational Note No. 1: Examples of approved means of achieving the indicated torque values include torque tools or devices such as shear bolts or breakaway-style devices with visual indicators that demonstrate that the proper torque has been applied.

Informational Note No. 2: The equipment manufacturer can be contacted if numeric torque values are not indicated on the equipment or if the installation instructions are not available. Informative Annex I of UL Standard 486A-486B, Standard for Safety-Wire Connectors, provides torque values in the absence of manufacturer’s recommendations.

Informational Note No. 3: Additional information for torqueing threaded connections and terminations can be found in Section 8.11 of NFPA 70B-2019, Recommended Practice for Electrical Equipment Maintenance.

Reason for Change: Disconnects are now required to identify of the source of the branch circuit or feeder for the disconnect at the disconnecting means enclosure (other than one- or two-family dwellings).

110.22 Identification of Disconnecting Means.

110.22 Identification of Disconnecting Means. (A) General. Each disconnecting means shall be legibly marked to indicate its purpose unless located and arranged so the purpose is evident.

In other than one- or two-family dwellings, the marking shall include the identification of the circuit source that supplies the disconnecting means. The marking shall be of sufficient durability to withstand the environment involved.

Reason for Change: Revisions to “Large Equipment” working space to addresses the hazards presented by two or more service disconnects with combined ratings of 1200 amps or more. Requirements also added to prevent open equipment doors from impeding the entry to or egress from the working space of large equipment.

110.26 Spaces About Electrical Equipment.

110.26 Spaces About Electrical Equipment. (C) Entrance to and Egress from Working Space.

(2) Large Equipment. For

large equipment

rated 1200 amperes or more and over 1.8 m (6 ft) wide that contains overcurrent devices, switching devices, or control devices, there shall be one entrance to and egress from the required working space not less than 610 mm (24 in.) wide and 2.0 m (6 ½ ft) high at each end of the working space.

This requirement shall apply to either of the following conditions: (1) For equipment rated 1200 amperes or more and over 1.8 m (6 ft) wide (2) For service disconnecting means installed in accordance with 230.71 where the combined ampere rating is 1200 amperes or more and over 1.8 m (6 ft) wide

Open equipment doors shall not impede the entry to or egress from the working space.

A single entrance to and egress from the required working space shall be permitted where either of the conditions in 110.26(C)(2)(a) or (C)(2)(b) is met.

(a) Unobstructed Egress. Where the location permits a continuous and unobstructed way of egress travel, a single entrance to the working space shall be permitted. (b) Extra Working Space. Where the depth of the working space is twice that required by 110.26(A) (1), a single entrance shall be permitted. It shall be located such that the distance from the equipment to the nearest edge of the entrance is not less than the minimum clear distance specified in Table 110.26(A)(1) for equipment operating at that voltage and in that condition.

Reason for Change: Revision added to clarity appropriate hardware (equipped with listed panic hardware or listed fire exit hardware) for personnel doors within 7.6 m (25 ft) from the working space around electrical equipment rated 800 amperes or more.

110.26 Spaces About Electrical Equipment.

110.26 Spaces About Electrical Equipment. (3) Personnel Doors. Where equipment rated 800

amperes or more that contains overcurrent devices, switching devices, or control devices is installed and there is a personnel door(s) intended for entrance to and egress from the working space less than 7.6 m (25 ft) from the nearest edge of the working space, the door(s) shall open in the direction of egress and be equipped with listed panic hardware

or listed fire exit hardware. Informational Note: For information on panic hardware, see UL 305, Standard for Safety for Panic Hardware. For fire exit hardware, see UL 305, Standard for Panic

Hardware, and UL 10C, Standard for Safety for Positive Pressure Fire Tests of Door Assemblies.

Article 200 – Use and Identification of Grounded Conductors

200.3 Connection to Grounded SystemReason for Change: The grounded conductors of premises wiring systems are required to be electrically connected to the supply system grounded conductor. This applied to all premises wiring, not just interior wiring.

200.3 Connection to Grounded System.

200.3 Connection to Grounded System. Premises Grounded conductors of premises wiring

systems shall be electrically connected to a the supply system

unless the latter contains, for any grounded conductor

of the interior system, a corresponding conductor that is grounded to ensure a common, continuous grounded system. For the purpose of this section, electrically connected shall mean

connected so as to be making a direct electrical connection capable of carrying current, as distinguished from

connection through electromagnetic induction induced currents.

Exception: Listed

utility-interactive inverters identified for use in distributed resource generation systems such as photovoltaic and fuel cell power systems shall be permitted to be connected to premises wiring without a grounded conductor

where if the connected premises wiring or utility system includes a grounded conductor.

Reason for Change: The means of identification of the grounded conductor terminals or screws for such things as receptacles can now be achieved by a metal or metal coating that is not only substantially white in color, but “substantially silver” in color as well.

200.10 Identification of Terminals. (B) Receptacles, Plugs, and Connectors.

200.10 Identification of Terminals. (B) Receptacles, Plugs, and Connectors. Receptacles, polarized attachment plugs, and cord connectors for plugs and polarized plugs shall have the terminal intended for connection to the grounded conductor identified as follows:

(1) Identification shall be by a metal or metal coating that is substantially white

or silver in color or by the word white or the letter W located adjacent to the identified terminal. (2) If the terminal is not visible, the conductor entrance hole for the connection shall be colored white or marked with the word white or the letter W.

Informational Note: See 250.126 for identification of wiring device equipment grounding conductor terminals.

Article 210 – Branch Circuits

210.8 Ground-Fault Circuit-Interrupter Protection for PersonnelReason for Change: Revision removes “door” and “doorway” as items the supply cord of an appliance connected to the receptacle should not pass

through in order to satisfy measurement requirements for GFCI protection.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. Ground-fault circuit-interrupter protection for personnel shall be provided as required in 210.8(A) through

(E)(F). The ground-fault circuit interrupter shall be installed in a readily accessible location.

Informational Note No. 1: See 215.9 for groundfault circuit-interrupter protection for personnel on feeders.

Informational Note No. 2: See 422.5(A) for GFCI requirements for appliances.

Informational Note No. 3: See 555.9 for GFCI requirements for boat hoists.

Informational Note No. 4: Additional GFCI requirements for specific circuits and equipment are contained in Chapters 4, 5, and 6.

For the purposes of this section, when determining

the distance from receptacles the distance shall be measured as the shortest path the

supply cord of an appliance connected to the receptacle would follow without piercing a floor, wall, ceiling, or fixed barrier, or

the shortest path without passing through a door, doorway, or window.

Reason for Change: Dwelling unit GFCI protection has been expanded to all 125-volt through 250-volt receptacles supplied by single-phase branch circuits rated 150 volts or less to ground installed in the specified areas of 210.8(A).

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. (A) Dwelling Units.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. (A) Dwelling Units. All 125-volt

through 250-volt,

single-phase, 15- and 20-ampere receptacles installed in the locations specified in 210.8(A)(1) through

(10)(11) and supplied by single-phase branch circuits rated 150 volts or less to ground shall have groundfault circuit-interrupter protection for personnel.

(1) Bathrooms (2) Garages, and also accessory buildings that have a floor located at or below grade level not intended as habitable rooms and limited to storage areas, work areas, and areas of similar use (3) Outdoors

Exception to (3): Receptacles that are not readily accessible and are supplied by a branch circuit dedicated to electric snow-melting, deicing, or pipeline and vessel heating equipment shall be permitted to be installed in accordance with 426.28 or 427.22, as applicable.

(4) Crawl spaces — at or below grade level

(5) Basements Unfinished portions or areas of the basement not intended as habitable roomsException to (5): A receptacle supplying only a permanently installed fire alarm or burglar alarm system shall not be required to have ground-fault circuit-interrupter protection.

Informational Note: See 760.41(B) and 760.121(B) for power supply requirements for fire alarm systems. Receptacles installed under the exception to 210.8(A)(5) shall not be considered as meeting the requirements of 210.52(G).

(6) Kitchens — where the receptacles are installed to serve the countertop surfaces

(7) Sinks — where receptacles are installed within 1.8 m (6 ft) from the top inside edge of the bowl of the sink

(8) Boathouses

(9) Bathtubs or shower stalls — where receptacles are installed within 1.8 m (6 ft) of the outside edge of the bathtub or shower stall

(10) Laundry areas

Exception to (1) through (3), (5) through (8), and (10): Listed locking support and mounting receptacles utilized in combination with compatible attachment fittings installed for the purpose of serving a ceiling luminaire or ceiling fan shall not be required to be ground-fault circuit-interrupter protected. If a general-purpose convenience receptacle is integral to the ceiling luminaire or ceiling fan, GFCI protection shall be provided.

(11) Indoor damp and wet locations

Reason for Change: GFCI protection now required for ALL dwelling unit basements(not just unfinished portions of basements).

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. (A) Dwelling Units.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. (A) Dwelling Units. All 125-volt

through 250- volt, single-phase, 15- and 20-ampere receptacles installed in the locations specified in 210.8(A)(1) through

(10)(11) and supplied by single-phase branch circuits rated 150 volts or less to ground shall have ground-fault circuit-interrupter protection for personnel.

(5) Basements Unfinished portions or areas of the basement not intended as habitable rooms

Reason for Change: GFCI protection is now required at indoor damp and wet locations of dwelling units.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel.

(A) Dwelling Units. All 125-volt through 250- volt, single-phase, 15- and 20-ampere receptacles installed in the locations specified in 210.8(A)(1) through (10)(11) and supplied by single-phase branch circuits rated 150 volts or less to ground shall have ground-fault circuit-interrupter protection for personnel.

(11) Indoor damp and wet locations[/box]

210.8(B) GFCI Requirements at Non-Dwelling Unit LocationsReason for Change: New GFCI requirements at non-dwelling unit locations were added for damp locations, accessory buildings, laundry areas, and areas around bathtubs and shower stalls.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. Ground-fault circuit-interrupter protection for personnel shall be provided as required in 210.8(A) through

(E)(F). The ground-fault circuit interrupter shall be installed in a readily accessible location.

(See NEC for remainder of Code text)

(B) Other Than Dwelling Units. All

single-phase 125-volt through 250-volt receptacles

supplied by single-phase branch circuits rated 150 volts

or less to ground or less, 50 amperes or less and

all receptacles supplied by three-phase

receptacles branch circuits rated 150 volts

or less to ground

or less, 100 amperes or less installed in the

following locations

specified in 210.8(B)(1) through (B)(12) shall have ground-fault circuit-interrupter protection for personnel.

(1) Bathrooms

(2) Kitchens

or areas with a sink and permanent provisions for either food preparation or cooking (3) Rooftops Exception: Receptacles on rooftops shall not be required to be readily accessible other than from the rooftop.

(4) Outdoors

Exception No. 1 to (3) and (4): Receptacles that are not readily accessible and are supplied by a branch circuit dedicated to electric snow-melting, deicing, or pipeline and vessel heating equipment shall be permitted to be installed in accordance with 426.28 or 427.22, as applicable.

Exception No. 2 to (4): In industrial establishments only, where the conditions of maintenance and supervision ensure that only qualified personnel are involved, an assured equipment grounding conductor program as specified in 590.6(B) (2) shall be permitted for only those receptacle outlets used to supply equipment that would create a greater hazard if power is interrupted or having a design that is not compatible with GFCI protection.

(5) Sinks — where receptacles are installed within 1.8 m (6 ft) from the top inside edge of the bowl of the sink

Exception No. 1 to (5): In industrial laboratories, receptacles used to supply equipment where removal of power would introduce a greater hazard shall be permitted to be installed without GFCI protection.

Exception No. 2 to (5): For Receptacles located in patient bed locations of

Category 2 (general care) or

Category 1 (critical care) spaces of health care facilities

other than those covered under 210.8(B) (1), GFCI protection shall not be required shall be permitted to comply with 517.21.

(6) Indoor

damp and wet locations

(7) Locker rooms with associated showering facilities

(8) Garages,

accessory buildings, service bays, and similar areas other than vehicle exhibition halls and showrooms

(9) Crawl spaces — at or below grade level

(10) Unfinished

portions or areas of the basement

s not intended as habitable rooms Exception to (1) through (5), (8), and (10): Listed locking support and mounting receptacles utilized in combination with compatible attachment fittings installed for the purpose of serving a ceiling luminaire or ceiling fan shall not be required to be ground-fault circuit-interrupter protected. If a general-purpose convenience receptacle is integral to the ceiling luminaire or ceiling fan, GFCI protection shall be provided.

(11) Laundry areas

(12) Bathtubs and shower stalls — where receptacles are installed within 1.8 m (6 ft) of the outside edge of the bathtub or shower stall

Reason for Change: Additional language was added to clarify that areas not defined as a kitchen such as ice cream parlors, coffee shops, smoothie stores, etc., with a sink and permanent provisions for either food preparation or cooking have the same potential for shock hazards as a kitchen.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. Ground-fault circuit-interrupter protection for personnel shall be provided as required in 210.8(A) through

(E)(F). The ground-fault circuit interrupter shall be installed in a readily accessible location.

(See NEC for remainder of Code text)

(B) Other Than Dwelling Units. All

single-phase 125-volt through 250-volt receptacles

supplied by single-phase branch circuits rated 150 volts

or less to ground

or less, 50 amperes or less and

all receptacles supplied by three-phase

receptacles branch circuits rated 150 volts

or less to ground

or less, 100 amperes or less installed in the

following locations

specified in 210.8(B)(1) through (B)(12) shall have ground-fault circuit-interrupter protection for personnel.

(2) Kitchens or areas with a sink and permanent provisions for either food preparation or cooking

Reason for Change: New List Item (D) correlates the requirements found in 422.5(B) (Type of GFCI protection for appliances) and refers to the list of GFCI requirements for appliances in 422.5(A) for continued consistency as the list is modified in future Code editions.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. Ground-fault circuit-interrupter protection for personnel shall be provided as required in 210.8(A) through

(E)(F). The ground-fault circuit interrupter shall be installed in a readily accessible location.

(See NEC for remainder of Code text)

(D) Specific Appliances. Unless GFCI protection is provided in accordance with 422.5(B)(3) through (B)(5), the outlets supplying the appliances specified in 422.5(A) shall have GFCI protection in accordance with 422.5(B)(1) or (B)(2). Where the appliance is a vending machine as specified in 422.5(A)(5) and GFCI protection is not provided in accordance with 422.5(B)(3) or (B) (4), branch circuits supplying vending machines shall have GFCI protection in accordance with 422.5(B)(1) or (B)(2).

Reason for Change: GFCI protection is now required for the receptacles required by210.63 for HVAC equipment, indoor service equipment, and indoor equipment requiring dedicated equipment space.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. Ground-fault circuit-interrupter protection for personnel shall be provided as required in 210.8(A) through

(E)(F). The ground-fault circuit interrupter shall be installed in a readily accessible location.

(See NEC for remainder of Code text)

(E) Equipment Requiring Servicing. GFCI protection shall be provided for the receptacles required by 210.63.

Reason for Change: GFCI protection is now required on dwelling unit outdoor outlets supplied by single-phase branch circuit rated 150 volts or less to ground, and 50 amperes or less (including 240-volt AC units).

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel.

210.8 Ground-Fault Circuit-Interrupter Protection for Personnel. Ground-fault circuit-interrupter protection for personnel shall be provided as required in 210.8(A) through

(E)(F). The ground-fault circuit interrupter shall be installed in a readily accessible location.

(See NEC for remainder of Code text)

(F) Outdoor Outlets. All outdoor outlets for dwellings, other than those covered in 210.8(A) (3), Exception to (3), that are supplied by single- phase branch circuits rated 150 volts to ground or less, 50 amperes or less, shall have ground-fault circuit-interrupter protection for personnel.

Exception: Ground-fault circuit-interrupter protection shall not be required on lighting outlets other than those covered in 210.8(C).

Reason for Change: Additional text added to clarify that the only bathroom receptacles required to be supplied by the 20-ampere rated bathroom receptacle outlet branch circuits are the receptacle outlet(s) required by 210.52(D) and any other receptacles installed in the bathroom that serve a countertop or work surface.

210.11 Branch Circuits Required (C) Dwelling Units. (3)

210.11 Branch Circuits Required (C) Dwelling Units. (3) Bathroom Branch Circuits. In addition to the number of branch circuits required by other parts of this section,

at least one

or more 120-volt, 20-ampere branch circuit shall be provided to supply the bathroom(s) receptacle outlet(s)

required by 210.52(D) and any countertop and similar work surface receptacle outlets. Such circuits shall have no other outlets.

Exception: Where the 20-ampere circuit supplies a single bathroom, outlets for other equipment within the same bathroom shall be permitted to be supplied in accordance with 210.23(A)(1) and (A)(2).

Reason for Change: Garage receptacle outlet 120-volt, 20-ampere branch circuits are only required for the receptacles required by 210.52(G)(1) for attached garages and in detached garages with electric power.

210.11 Branch Circuits Required (C) Dwelling Units. (4)

210.11 Branch Circuits Required (C) Dwelling Units. (4) Garage Branch Circuits. In addition to the number of branch circuits required by other parts of this section, at least one 120-volt, 20-ampere branch circuit shall be installed to supply receptacle outlets in

required by 210.52(G)(1) for attached garages and in detached garages with electric power. This circuit shall have no other outlets.

Exception: This circuit shall be permitted to supply readily accessible outdoor receptacle outlets.

Reason for Change: AFCI protection has been expanded to patient sleeping rooms in nursing homes and limited-care facilities.

210.12 Arc-Fault Circuit-Interrupter Protection.

210.12 Arc-Fault Circuit-Interrupter Protection. Arc-fault circuit-interrupter protection shall be provided as required in 210.12(A), (B), (C), and (D). The arc-fault circuit interrupter shall be installed in a readily accessible location.

(C) Guest Rooms and, Guest Suites, and Patient Sleeping Rooms in Nursing Homes and Limited- Care Facilities. All 120-volt, single-phase, 15- and 20-ampere branch circuits supplying outlets and devices installed in guest rooms and guest suites of hotels and motels

and patient sleeping rooms in nursing homes and limited-care facilities shall be protected by any of the means described in 210.12(A)(1) through (6).

Reason for Change: Guest rooms and guest suites of hotels and motels have been

added to the areas requiring AFCI protection for extensions and modifications of existing occupancies.

210.12 Arc-Fault Circuit-Interrupter Protection. (D) Branch Circuit Extensions or Modifications – Dwelling Units and, Dormitory Units,

210.12 Arc-Fault Circuit-Interrupter Protection. (D) Branch Circuit Extensions or Modifications – Dwelling Units and, Dormitory Units, and Guest Rooms and Guest Suites. In Where branch circuit wiring for any of the areas specified in 210.12(A)

or, (B),

where branch-circuit wiring or (C) is modified, replaced, or extended, the branch circuit shall be protected by one of the following:

(1) A listed combination-type AFCI located at the origin of the branch circuit By any of the means described in 210.12(A)(1) through (A)(6) (2) A listed outlet branch-circuit-type AFCI located at the first receptacle outlet of the existing branch circuit

Exception: AFCI protection shall not be required where the extension of the existing branch circuit conductors is not more than 1.8 m (6 ft) and does not include any additional outlets or devices, other than splicing devices. This measurement shall not include the conductors inside an enclosure, cabinet, or junction box.

Reason for Change: New section added prohibiting GFCI devices, AFCI devices, and ground-fault protection equipment from being reconditioned.

210.15 Reconditioned Equipment.

210.15 Reconditioned Equipment. The following shall not be reconditioned:

(1) Equipment that provides ground-fault circuit- interrupter protection for personnel (2) Equipment that provides arc-fault circuit-interrupter protection (3) Equipment that provides ground-fault protection of equipment

Reason for Change: Revision clarifies that the receptacle outlets installed for countertop or work surfaces [210.52(C)] are not permitted to satisfy the requirement for receptacle outlet placement (wall spacing) as provided in 210.52(A).

210.52 Dwelling Unit Receptacle Outlets. (C) Countertops and Work Surfaces.

210.52 Dwelling Unit Receptacle Outlets. (C) Countertops and Work Surfaces. In kitchens, pantries, breakfast rooms, dining rooms, and similar areas of dwelling units, receptacle outlets for countertop and work surfaces

that are 300 mm (12 in.) or wider shall be installed in accordance with 210.52(C)(1) through

(C)(5) (C) (3) and shall not be considered as the receptacle outlets required by 210.52(A). For the purposes of this section, where using multioutlet assemblies, each 300 mm (12 in.) of multioutlet assembly containing two or more receptacles installed in individual or continuous lengths shall be considered to be one receptacle outlet.

Reason for Change: Revision creates two separate List Items for wall space, and island and peninsular countertops and work surfaces. For island and peninsular countertop and work surfaces, the horizontal measurement was changed to a square foot calculation to determine the number of receptacles required. One receptacle outlet is required for the first 9 sq. ft of countertop and an additional receptacle outlet is required for each additional 18 sq. ft. or fraction thereof.

210.52 Dwelling Unit Receptacle Outlets. (C) Countertops and Work Surfaces.

210.52 Dwelling Unit Receptacle Outlets. (C) Countertops and Work Surfaces. In kitchens, pantries, breakfast rooms, dining rooms, and similar areas of dwelling units, receptacle outlets for countertop and work surfaces

that are 300 mm (12 in.) or wider shall be installed in accordance with 210.52(C)(1) through

(C)(5) (C)(3) and shall not be considered as the receptacle outlets required by 210.52(A). For the purposes of this section, where using multioutlet assemblies, each 300 mm (12 in.) of multioutlet assembly containing two or more receptacles installed in individual or continuous lengths shall be considered to be one receptacle outlet.

(1) Wall Spaces Countertop and Work Surface. A receptacle outlet shall be installed at each wall countertop and work surface that is 300 mm (12 in.) or wider. Receptacle outlets shall be installed so that no point along the wall line is more than 600 mm (24 in.) measured horizontally from a receptacle outlet in that space.

Exception: Receptacle outlets shall not be required on a wall directly behind a range, counter-mounted cooking unit, or sink in the installation described in Figure 210.52(C)(1).

(2) Island and Peninsular Countertops and Work Surfaces Spaces. Receptacle outlets shall be installed in accordance with 210.52(C)(2)(a) and (C)(2)(b).

(a) At least one receptacle shall be provided for the first 0.84 m2 (9 ft2), or fraction thereof, of the countertop or work surface. A receptacle outlet shall be provided for every additional 1.7 m2 (18 ft2), or fraction thereof, of the countertop or work surface

installed at each island countertop space with a long dimension of 600 mm (24 in.) or greater and a short dimension of 300 mm (12 in.) or greater. (b) At least one receptacle outlet shall be located within 600 mm (2 ft) of the outer end of a peninsular countertop or work surface. Additional required receptacle outlets shall be permitted to be located as determined by the installer, designer, or building owner. The location of the receptacle outlets shall be in accordance with 210.52(C)(3). A peninsular countertop shall be measured from the connected perpendicular wall.

(3) Peninsular Countertop Spaces. At least one receptacle outlet shall be installed at each peninsular countertop long dimension space with a long dimension of 600 mm (24 in.) or greater and a short dimension of 300 mm (12 in.) or greater. A peninsular countertop is measured from the connected perpendicular wall.

(5) (3) Receptacle Outlet Location. Receptacle outlets shall be located

in one or more of the following: (1) On or Above Countertop or Work Surfaces: On or above, but not more than 500 mm (20 in.) above, the countertop or work surface.

(2) In Countertop or Work Surfaces: Receptacle outlet assemblies listed for use in countertops or work surfaces shall be permitted to be installed in countertops or work surfaces.

(3) Below Countertop or Works Surfaces: To comply with the following conditions (1) and (2), receptacle outlets shall be permitted to be mounted Not more than 300 mm (12 in.) below the countertop or work surface. Receptacles installed below a countertop or work surface shall not be located where the countertop or work surface extends more than 150 mm (6 in.) beyond its support base.

(1) Construction for the physically impaired

(2) On island and peninsular countertops or work surface where the surface is flat across its entire surface (no backsplashes, dividers, etc.) and there are no means to mount a receptacle within 500 mm (20 in.) above the countertop or work surface, such as an overhead cabinet

Receptacle outlets rendered not readily accessible by appliances fastened in place, appliance garages, sinks, or rangetops as covered in 210.52(C)(1), Exception, or appliances occupying assigned spaces shall not be considered as these required outlets.

Informational Note No. 1: See 406.5(E) and 406.5(G) for installation of receptacles in countertops and 406.5(F) and 406.5(G) for installation of receptacles in work surfaces.

See 380.10 for installation of multioutlet assemblies. Informational Note No. 2: See Annex J and ANSI/ICC A117.1-2009, Standard on Accessible and Usable Buildings and Facilities.

Reason for Change: The required receptacle outlet for balconies, decks, and porches is also required at decks that are installed in a freestanding manner where connection to the actual dwelling is not made at any point.

210.52 Dwelling Unit Receptacle Outlets (3) Balconies, Decks, and Porches.

210.52 Dwelling Unit Receptacle Outlets (3) Balconies, Decks, and Porches. Balconies, decks, and porches that are

attached to within 102 mm (4 in.) horizontally of the dwelling unit and

are accessible from inside the dwelling unit shall have at least one receptacle outlet accessible from the balcony, deck, or porch. The receptacle outlet shall not be located more than 2.0 m (6 . ft) above the balcony, deck, or porch walking surface.

Reason for Change: Revisions recognize non-rectangular meeting rooms (such as round-shaped meeting rooms). Revision also provides flexibility to provide a floor receptacle outlet or an outlet to supply receptacles for hardwired furniture with receptacles.

210.71 210.65 Meeting Rooms. (A) General. Each meeting room of not more than 93 m2 (1000 ft2) in other than dwelling units shall have outlets for nonlocking-type, 125-volt, 15- or 20-ampere receptacles. The outlets shall be installed in accordance with 210.

7165(B). Where a room or space is provided with movable partition( s), each room size shall be determined with the partition in the position that results in the smallest size meeting room.

Informational Note No. 1: For the purposes of this section, meeting rooms are typically designed or intended for the gathering of seated occupants for such purposes as conferences, deliberations, or similar purposes, where portable electronic equipment such as computers, projectors, or similar equipment is likely to be used.

Informational Note No. 2: Examples of rooms that are not meeting rooms include auditoriums, schoolrooms, and coffee shops.

(B) Receptacle Outlets Required. The total number of receptacle outlets, including floor outlets and receptacle outlets in fixed furniture, shall not be less than as determined in (1) and (2).

These receptacle outlets shall be permitted to be located as determined by the designer or building owner. (1) Receptacle Outlets in Fixed Walls. The required number of receptacle outlets shall be

installed determined in accordance with 210.52(A) (1) through (A)(4).

These receptacle outlets shall be permitted to be located as determined by the installer, designer, or building owner. (2) Floor Receptacle Outlets. A meeting room with any floor dimension that is

at least 3.7 m (12 ft)

wide or greater in any direction and that has a

floor area of at least 20 m2 (215 ft2) shall have at least one floor receptacle outlet

located in the floor,

or at least one floor outlet to serve receptacle(s), located at a distance not less than 1.8 m (6 ft) from any fixed wall for each 20 m2 (215 ft2) or major portion of floor space.

Informational Note No. 1: See Section 314.27(B) for floor boxes used for receptacles located in the floor.

Informational Note No. 2: See Article 518 for assembly occupancies designed for 100 or more persons.

Article 215 – Feeders

215.9 Feeders in GFCI in Readily Accessible LocationReason for Change: Revision provides correlation with GFCI protection requirements in 210.8 by removing the existing limitations of a feeder to provide GFCI protection to only 15 and 20-ampere receptacle branch circuits.

215.9 Ground-Fault Circuit-Interrupter Protection for Personnel.

215.9 Ground-Fault Circuit-Interrupter Protection for Personnel. Feeders

supplying 15- and 20-ampere receptacle branch circuits shall be permitted to be protected by a ground-fault circuit interrupter installed in a readily accessible location in lieu of the provisions for such interrupters as specified in 210.8 and 590.6(A).

Reason for Change: New exception added to permit temporary feeders to be used during repair, maintenance or emergencies without GFP of equipment. The time period permitted is not to exceed 90 days.

215.10 Ground-Fault Protection of Equipment.

215.10 Ground-Fault Protection of Equipment. Each feeder disconnect rated 1000 amperes or more and installed on solidly grounded wye electrical systems of more than 150 volts to ground, but not exceeding 600 volts phase-to-phase, shall be provided with ground-fault protection of equipment in accordance with the provisions of 230.95.

Informational Note: For buildings that contain health care occupancies, see

the requirements of 517.17.

Exception No. 1: The provisions of This section shall not apply to a disconnecting means for a continuous industrial process where a nonorderly shutdown will introduce additional or increased hazards.

Exception No. 2: The provisions of This section shall not apply if ground-fault protection of equipment is provided on the supply side of the feeder and on the load side of any transformer supplying the feeder.

Exception No. 3: If temporary feeder conductors are used to connect a generator to a facility for repair, maintenance, or emergencies, ground-fault protection of equipment shall not be required. Temporary feeders without ground-fault protection shall be permitted for the time period necessary but shall not exceed 90 days.

220 – Branch-Circuit, Feeder, and Service Load Calculations

220.12 and Table 220.12 Lighting Load for Non-Dwelling OccupanciesReason for Change: Section 220.12 and Table 220.12 has been extensively revised. Reduced lighting loads in most occupancies was achieved. Dwelling and multi-family dwelling units were moved out of Table 220.12 and referenced in revised 220.14(J).

220.12 Lighting Load for Specified Non-Dwelling Occupancies. (A) General.

220.12 Lighting Load for Specified Non-Dwelling Occupancies. (A) General. A unit load of not less than that specified in Table 220.12 for

occupancies specified shall constitute non-dwelling occupancies and the floor area determined in 220.11 shall be used to calculate the minimum lighting load.

The floor area for each floor shall be calculated from the outside dimensions of the building, dwelling unit, or other area involved. For dwelling units, the calculated floor area shall not include open porches, garages, or unused or unfinished spaces not adaptable for future use. Motors rated less than 1⁄8 HP and connected to a lighting circuit shall be considered general lighting load. Informational Note: The unit values

of Table 220.12 are based on minimum load conditions and 100 percent power factor and may not provide sufficient capacity for the installation contemplated.

(B) Energy Code. Exception No. 1: Where the building is designed and constructed to comply with an energy code adopted by the local authority, the lighting load shall be permitted to be calculated

at using the

unit values specified in the energy code where the following conditions are met:

(1) A power monitoring system is installed that will provide continuous information regarding the total general lighting load of the building.

(2) The power monitoring system will be set with alarm values to alert the building owner or manager if the lighting load exceeds the values set by the energy code.

Automatic means to take action to reduce the connected load shall be permitted. (3) The demand factors specified in 220.42 are not applied to the general lighting load.

(4) The continuous load multiplier of 125 percent shall be applied. Exception No. 2 Where a building is designed and constructed to comply with an energy code adopted by the local authority and specifying an overall lighting density of less than 13.5 volt-amperes/m2 (1.2 volt-amperes/ft2), the unit lighting loads in

Table 220.12 for office and bank areas within the building shall be permitted to be reduced by 11 volt-amperes/ m2 (1 volt-amperes/ft2).

Table 220.12 General Lighting Loads by

Non-Dwelling Occupancy

(See NEC and Table 220.12 provided in this text)

Reason for Change: The NEC calculation of 3.0 watts per square foot for dwelling units was moved from Table 220.12 to 220.14(J) and reference to Table 220.12 was removed from 220.14(J).

220.14 Other Loads – All Occupancies (J) Dwelling

220.14 Other Loads – All Occupancies (J) Dwelling Occupancies Units. In one-family, two-family, and multifamily dwellings

and in guest rooms or guest suites of hotels and motels, the

minimum unit load shall be not less than 33 VA volt-amperes/m2 (3 VA volt-amperes/ft2). The lighting and receptacle outlets specified in

220.14(J)(1), (J)(2), and (J)(3) are included in the minimum

general lighting load calculations of 20.12 unit load. No additional load calculations shall be required for such outlets.

The minimum lighting load shall be determined using the minimum unit load and the floor area as determined in 220.11 for dwelling occupancies. Motors rated less than 1⁄8 hp and connected to a lighting circuit shall be considered part of the minimum lighting load. (1) All general-use receptacle outlets of 20-ampere rating or less, including receptacles connected to the circuits in 210.11(C)(3)

and 210.11(C)(4) (2) The receptacle outlets specified in 210.52(E) and (G)

(3) The lighting outlets specified in 210.70(A) and (B)

Reason for Change: Hospitals were deleted from Table 220.42 and is now required to include 100 percent of the total VA of the calculated lighting load.

220.42 General Lighting.

220.42 General Lighting. The demand factors specified in Table 220.42 shall apply to that portion of the total branch-circuit load calculated for general illumination. They shall not be applied in determining the number of branch circuits for general illumination.

Table 220.42 Lighting Load Demand Factors

(See NEC and supplied table for complete NEC text of table)

Reason for Change: All household electric cooking equipment that is fastened in place (not just an electric range) has been added to the list of appliances that cannot be included in the four or more appliances eligible for a 75% derating demand factor.

220.53 Appliance Load — Dwelling Unit(s).

220.53 Appliance Load — Dwelling Unit(s). It shall be permissible to apply a demand factor of 75 percent to the nameplate rating load of four or more appliances

rated 1/4 hp or greater, or 500 watts or greater, that are fastened in place,

other than electric ranges, clothes dryers, space-heating equipment, or air-conditioning equipment,

and that are served by the same feeder or service in a one-family, two-family, or multifamily dwelling.

This demand factor shall not apply to: (1) Household electric cooking equipment that is fastened in place

(2) Clothes dryers

(3) Space heating equipment

(4) Air-conditioning equipment

225 – Outside Branch Circuits and Feeders

225.30(B) Special Conditions for More than One Outside FeederReason for Change: New text added that will permit more than one feeder (up to six feeders) under very limited circumstances (same panelboard, grouped, etc.).

225.30 Number of Supplies. (A) Special Conditions. (B) Common Supply Equipment.

225.30 Number of Supplies. (A) Special Conditions. (B) Common Supply Equipment. Where feeder conductors originate in the same panelboard, switchboard, or other distribution equipment, and each feeder terminates in a single disconnecting means, not more than six feeders shall be permitted. Where more than one feeder is installed in accordance with this section, all feeder disconnects supplying the building or structure shall be grouped in the same location, and the requirements of 225.33 shall not apply. Each disconnect shall be marked to indicate the load served.

(C) Special Occupancies. (D) Capacity Requirements. (E) Different Characteristics. (F) Documented Switching Procedures. (See NEC for complete Code text)

230 – Services

230.46 Spliced and Tapped ConductorsReason for Change: Requirement for power distribution blocks installed on service conductors required to be marked “suitable for use on the line side of the service equipment” or equivalent was moved to 230.46. All devices used to splice service conductors must be listed and marked as “suitable for use on the line side of the service equipment” or equivalent by January 1, 2023.

230.46 Spliced and Tapped Conductors.

230.46 Spliced and Tapped Conductors. Service-entrance conductors shall be permitted to be spliced or tapped in accordance with 110.14, 300.5(E), 300.13, and 300.15. Power distribution blocks, pressure connectors, and devices for splices and taps shall be listed.

Power distribution blocks installed on service conductors shall be marked “suitable for use on the line side of the service equipment” or equivalent. Effective January 1, 2023, pressure connectors and devices for splices and taps installed on service conductors shall be marked “suitable for use on the line side of the service equipment” or equivalent.

Reason for Change: Previous provision for barriers at service panelboards, switchboards, and switchgear has been moved to Article 230 to apply to all service equipment.

230.62 Service Equipment – Enclosed or Guarded.

230.62 Service Equipment – Enclosed or Guarded. Energized parts of service equipment shall be enclosed as specified in 230.62(A) or guarded as specified in 230.62(B).

(C) Barriers. Barriers shall be placed in service equipment such that no uninsulated, ungrounded service busbar or service terminal is exposed to inadvertent contact by persons or maintenance equipment while servicing load terminations.

Reason for Change: New requirement added to require surge protection on all services at dwelling units.

230.67 Surge Protection. (A) Surge-Protective Device.

230.67 Surge Protection. (A) Surge-Protective Device. All services supplying dwelling units shall be provided with a surge-protective device (SPD).

(B) Location. The SPD shall be an integral part of the service equipment or shall be located immediately adjacent thereto.

Exception: The SPD shall not be required to be located in the service equipment as required in (B) if located at each next level distribution equipment downstream toward the load.

(C) Type. The SPD shall be a Type 1 or Type 2 SPD.

(D) Replacement. Where service equipment is replaced, all of the requirements of this section shall apply.

Reason for Change: Revision eliminates more than one service disconnecting means in the same panelboard or other enclosure. Continues to retain the six service disconnect rule for services; however, the permission for up to six service disconnects is modified to require installation in separate enclosures only.

230.71 Maximum Number of Disconnects.

230.71 Maximum Number of Disconnects. Each service shall have only one disconnecting means unless the requirements of 230.71(B) are met.

(A) General. The service disconnecting means for each service permitted by 230.2, or for each set of service-entrance conductors permitted by 230.40, Exception No. 1, 3, 4, or 5, shall consist of not more than six switches or sets of circuit breakers, or a combination of not more than six switches and sets of circuit breakers, mounted in a single enclosure, in a group of separate enclosures, or in or on a switchboard or in switchgear. There shall be not more than six sets of disconnects per service grouped in any one location.

For the purpose of this section, disconnecting means installed as part of listed equipment and used solely for the following shall not be considered a service disconnecting means:

(1) Power monitoring equipment

(2) Surge-protective device(s)

(3) Control circuit of the ground-fault protection system

(4) Power-operable service disconnecting means

(B) Single-Pole Units Two to Six Service Disconnecting Means. Two or three single-pole switches or breakers, capable of individual operation, shall be permitted on multiwire circuits, one pole for each ungrounded conductor, as one multipole disconnect, provided they are equipped with identified handle ties or a master handle to disconnect all conductors of the service with no more than six operations of the hand.

Two to six service disconnects

shall be permitted for each service permitted by 230.2 or for each set of service- entrance conductors permitted by 230.40, Exception No. 1, 3, 4, or 5.

The two to six service disconnecting means shall be permitted to consist of a combination of any of the following: (1) Separate enclosures with a main service disconnecting means in each enclosure

(2) Panelboards with a main service disconnecting means in each panelboard enclosure (3) Switchboard(s) where there is only one service disconnect in each separate vertical section where there are barriers separating each vertical section (4) Service disconnects in switchgear or metering centers where each disconnect is located in a separate compartment

Informational Note No. 1: See 408.36, Exception No. 1 and Exception No. 3, for service equipment in certain panelboards, and see 430.95 for service equipment in motor control centers

Metering centers are addressed in UL 67, Standard for Panelboards. Informational Note No. 2: Examples of separate enclosures with a main service disconnecting means in each enclosure include but are not limited to motor control centers, fused disconnects, circuit breaker enclosures, and transfer switches that are suitable for use as service equipment.

Reason for Change: New requirement added to require an emergency disconnect at a readily accessible outdoor location for dwelling units.

230.85 Emergency Disconnects.

230.85 Emergency Disconnects. For one- and two-family dwelling units, all service conductors shall terminate in disconnecting means having a short-circuit current rating equal to or greater than the available fault current, installed in a readily accessible outdoor location. If more than one disconnect is provided, they shall be grouped. Each disconnect shall be one of the following:

(1) Service disconnects marked as follows: EMERGENCY DISCONNECT, SERVICE DISCONNECT (2) Meter disconnects installed per 230.82(3) and marked as follows: EMERGENCY DISCONNECT, METER DISCONNECT, NOT SERVICE EQUIPMENT (3) Other listed disconnect switches or circuit breakers on the supply side of each service disconnect that are suitable for use as service equipment and marked as follows: EMERGENCY DISCONNECT, NOT SERVICE EQUIPMENT Markings shall comply with 110.21(B).

Article 240 – Overcurrent Protection

240.6(C) Restricted Access Adjustable-Trip Circuit BreakersReason for Change: New provision added to recognize modern electronic trip units to provide the ability to set a password to keep unauthorized users from changing the settings on an adjustable-trip circuit breaker(s) that has restricted access to the adjusting means.

240.6 Standard Ampere Ratings. (C) Restricted Access Adjustable-Trip Circuit Breakers.

240.6 Standard Ampere Ratings. (C) Restricted Access Adjustable-Trip Circuit Breakers. A circuit breaker(s) that has restricted access to the adjusting means shall be permitted to have an ampere rating(s) that is equal to the adjusted current setting (long-time pickup setting). Restricted access shall be

defined as located behind achieved by one of the following

methods: (1) Located behind removable and sealable covers over the adjusting means

(2) Located behind bolted equipment enclosure doors

(3) Located behind locked doors accessible only to qualified personnel

(4) Password protected, with password accessible only to qualified personnelReason for Change: Revision to 240.87(B)(5) clarifies that temporary adjustment of the instantaneous trip setting to achieve arc energy reduction shall not be permitted.

240.87 Arc Energy Reduction. (A) Documentation.

240.87 Arc Energy Reduction. (A) Documentation. Documentation shall be available to those authorized to design, install, operate, or inspect the installation as to the location of the circuit breaker(s).

Documentation shall also be provided to demonstrate that the method chosen to reduce clearing time is set to operate at a value below the available arcing current. (B) Method to Reduce Clearing Time. One of the following means shall be provided

and shall be set to operate at less than the available arcing current: (1) Zone-selective interlocking

(2) Differential relaying

(3) Energy-reducing maintenance switching with local status indicator

(4) Energy-reducing active arc flash mitigation system

(5) An instantaneous trip setting that is less than the available arcing current.

Temporary adjustment of the instantaneous trip setting to achieve arc energy reduction shall not be permitted. (6) An instantaneous override that is less than the available arcing current

(7) An approved equivalent means

(See NEC text for Informational Notes)

Reason for Change: New section added dealing with reconditioned equipment. Molded- case circuit breakers shall not be permitted to be reconditioned.

240.88 Reconditioned Equipment.

240.88 Reconditioned Equipment. Reconditioned equipment shall be listed as “reconditioned” and the original listing mark removed.

(A) Circuit Breakers. The use of reconditioned circuit breakers shall comply with (1) through (3):

(1) Molded-case circuit breakers shall not be permitted to be reconditioned.

(2) Low- and medium-voltage power circuit breakers shall be permitted to be reconditioned.

(3) High-voltage circuit breakers shall be permitted to be reconditioned.

(B) Components. The use of reconditioned trip units, protective relays, and current transformers shall comply with (1) and (2):

(1) Low-voltage power circuit breaker electronic trip units shall not be permitted to be reconditioned.

(2) Electromechanical protective relays and current transformers shall be permitted to be reconditioned.

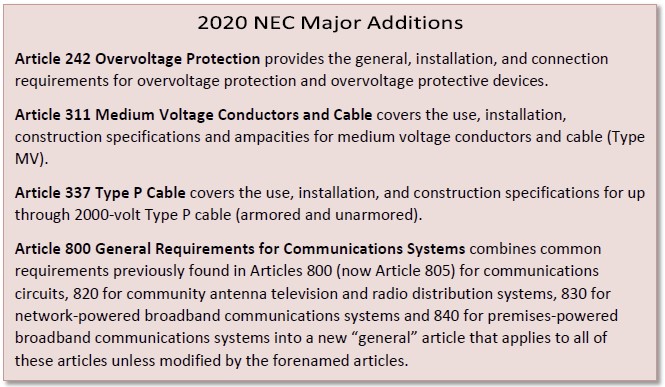

242 – Overvoltage Protection

Article 242 Overvoltage ProtectionReason for Change: New article added to provide the general, installation, and connection requirements for overvoltage protection and

overvoltage protective devices. Relocates Articles 280 and 285 into a new Article 242.

Article 242 Overvoltage Protection Part I. General 242.1 Scope.

Article 242 Overvoltage Protection Part I. General 242.1 Scope. This article provides the general requirements, installation requirements, and connection requirements for overvoltage protection and overvoltage protective devices. Part II covers surge-protective devices (SPDs) permanently installed on premises wiring systems of not more than 1000 volts, nominal, while Part III covers surge arresters permanently installed on premises wiring systems over 1000 volts, nominal.

Informational Note: Article 242 combines and replaces Articles 280 and 285 in NFPA 70-2017.

242.3 Other Articles. Table 242.3 Other Articles Part II. Surge-Protective Devices (SPDs), 1000 Volts or Less 242.6 Uses Not Permitted. 242.8 Listing. 242.10 Short-Circuit Current Rating. 242.12 Type 1 SPDs. (A) Installation. (B) At the Service. 242.14 Type 2 SPDs. (A) Service-Supplied Building or Structure. (B) Feeder-Supplied Building or Structure. (C) Separately Derived System. 242.16 Type 3 SPDs. 242.18 Type 4 and Other Component Type SPDs. 242.20 Number Required. 242.22 Location. 242.24 Routing of Connections. 242.26 Connection. 242.28 Conductor Size. 242.30 Connection Between Conductors. 242.32 Grounding Electrode Conductor Connections and Enclosures. Part III. Surge Arresters, Over 1000 Volts 242.40 Uses Not Permitted. 242.42 Surge Arrester Selection. (A) Rating. (1) Solidly Grounded Systems. (2) Impedance or Ungrounded System. (B) Silicon Carbide Types. 242.44 Number Required. 242.46 Location. 242.48 Routing of Surge Arrester Equipment Grounding Conductors. 242.50 Connection. 242.52 Surge-Arrester Conductors. 242.54 Interconnections. (A) Metal Interconnections. (1) Additional Grounding Connection. (2) Multigrounded Neutral System Connection. (B) Through Spark Gap or Device. (1) Ungrounded or Unigrounded Primary System. (2) Multigrounded Neutral Primary System. (C) By Special Permission. 242.56 Grounding Electrode Conductor Connections and Enclosures. (See NEC for complete text)

250 – Grounding and Bonding

250.25 Grounding Systems Permitted to Be Connected on the Supply Side of the Disconnect.Reason for Change: New section created to cover the requirements for grounding of

supply-side disconnects permitted to be connected on the supply-side of a service. Points user of the Code to 250.24.

250.25 Grounding Systems Permitted to Be Connected on the Supply Side of the Disconnect.

250.25 Grounding Systems Permitted to Be Connected on the Supply Side of the Disconnect. The grounding of systems connected on the supply side of the service disconnect, as permitted in 230.82, that are in enclosures separate from the service equipment enclosure shall comply with 250.25(A) or (B).

(A) Grounded System. If the utility supply system is grounded, the grounding of systems permitted to be connected on the supply side of the service disconnect and are installed in one or more separate enclosures from the service equipment enclosure shall comply with the requirements of 250.24(A) through (D).

(B) Ungrounded Systems. If the utility supply system is ungrounded, the grounding of systems permitted to be connected on the supply side of the service disconnect and are installed in one or more separate enclosures from the service equipment enclosure shall comply with the requirements of 250.24(E).

Reason for Change: Code language was formatted into a list format for improved clarity and usability and to clarify that terminations for aluminum or copper-clad aluminum conductors located in the interior of equipment “listed and identified for the environment” are separated from the earth and can be terminated within 450 mm (18 in.) of the earth.

250.64 Grounding Electrode Conductor Installation.

250.64 Grounding Electrode Conductor Installation. Grounding electrode conductors at the service, at each building or structure where supplied by a feeder(s) or branch circuit(s), or at a separately derived system shall be installed as specified in 250.64(A) through (F).

(A) Aluminum or Copper-Clad Aluminum Conductors. And identified for the environment

(1) Bare or covered conductors without an extruded polymeric covering shall not be installed where subject to corrosive conditions or be installed in direct contact with concrete.

(2) Terminations made within outdoor enclosures that are listed and identified for the environment shall be permitted within 450 mm (18 in.) of bottom of the enclosure.

(3) Bare Aluminum or copper-clad aluminum grounding electrode conductors external to buildings or equipment enclosures shall not be used where in direct contact with masonry or the earth or where subject to corrosive conditions. Where used outside, aluminum or copper-clad aluminum grounding electrode conductors shall not be terminated within 450 mm (18 in.) of the earth.

Reason for Change: Revision clarifies that Schedule 80 is required when PVC conduit is used for protection from physical damage for a grounding electrode conductor.

250.64 Grounding Electrode Conductor Installation (B) Securing and Protection Against Physical Damage.

250.64 Grounding Electrode Conductor Installation (B) Securing and Protection Against Physical Damage. Where exposed, a grounding electrode conductor or its enclosure shall be securely fastened to the surface on which it is carried. Grounding electrode conductors shall be permitted to be installed on or through framing members.

(1) Not Exposed to Physical Damage. A 6 AWG or larger copper or aluminum grounding electrode conductor not exposed to physical damage shall be permitted to be run along the surface of the building construction without metal covering or protection.

(2) Exposed to Physical Damage. A 6 AWG or larger copper or aluminum grounding electrode conductor exposed to physical damage shall be protected in rigid metal conduit (RMC), intermediate metal conduit (IMC),

Schedule 80 rigid polyvinyl chloride conduit (PVC), reinforced thermosetting resin conduit Type XW (RTRC-XW), electrical metallic tubing (EMT), or cable armor.

(3) Smaller Than 6 AWG. Grounding electrode conductors smaller than 6 AWG shall be protected in RMC, IMC,

Schedule 80 PVC, RTRC-XW, EMT, or cable armor.

Reason for Change: New provisions added to clarify that the rebar system in a footing or foundation is not suitable as the conductor to interconnect other grounding electrodes.

250.68(C)(3) Grounding Electrode Conductor and Bonding Jumper Connection to Grounding Electrodes.

250.68(C)(3) Grounding Electrode Conductor and Bonding Jumper Connection to Grounding Electrodes. The connection of a grounding electrode conductor at the service, at each building or structure where supplied by a feeder(s) or branch circuit(s), or at a separately derived system and associated bonding jumper(s) shall be made as specified 250.68(A) through (C).

(C) Grounding Electrode Conductor Connections. Grounding electrode conductors and bonding jumpers shall be permitted to be connected at the following locations and used to extend the connection to an electrode(s):

(1) Interior metal water piping…(see NEC for complete Code text)

(2) The metal structure frame of a building…(see NEC for complete Code text)

(3) A rebar-type concrete-encased electrode installed in accordance with 250.52(A)(3) with an additional rebar section extended from its location within the concrete foundation or footing to an accessible location that is not subject to corrosion shall be permitted for connection of grounding electrode conductors and bonding jumpers. The rebar extension shall not be exposed to contact with the earth without corrosion protection. in accordance with the following:

(a) The additional rebar section shall be continuous with the grounding electrode rebar or shall be connected to the grounding electrode rebar and connected together by the usual steel tie wires, exothermic welding, welding, or other effective means.

(b) The rebar extension shall not be exposed to contact with the earth without corrosion protection.

(c) Rebar shall not be used as a conductor to interconnect the electrodes of grounding electrode systems.

Reason for Change: Bonding jumper(s) used to bond metal water piping system(s) together are not required to be larger than 3/0 copper or 250 kcmil aluminum or copper- clad aluminum.

250.104 Bonding of Piping Systems and Exposed Structural Metal. (A) Metal Water Piping.

250.104 Bonding of Piping Systems and Exposed Structural Metal. (A) Metal Water Piping. The metal water piping system shall be bonded as required in

250.104(A) (1), (A)(2), or (A)(3)

of this section. (1) General. Metal water piping system(s) installed in or attached to a building or structure shall be bonded to any of the following:

(1) Service equipment enclosure

(2) Grounded conductor at the service

(3) Grounding electrode conductor, if of sufficient size

(4) One or more grounding electrodes used, if the grounding electrode conductor or bonding jumper to the grounding electrode is of sufficient size The bonding jumper(s) shall be installed in accordance with 250.64(A), 250.64(B), and 250.64(E). The points of attachment of the bonding jumper(s) shall be accessible. The bonding jumper(s) shall be sized in accordance with Table 250.102(C)(1) except

that it shall not be required to be larger than 3/0 copper or 250 kcmil aluminum or copper-clad aluminum and except as permitted in 250.104(A) (2) and 250.104(A)(3).

Reason for Change: Revision clarifies the sizing requirements for bonding jumper(s) used for bonding metal water piping systems when a building or structure is supplied by a feeder or branch circuit. Reference changed from Table 250.102(C)(1) to 250.102(D) (and Table 250.122).

250.104 Bonding of Piping Systems and Exposed Structural Metal. (A) Metal Water Piping.

250.104 Bonding of Piping Systems and Exposed Structural Metal. (A) Metal Water Piping. The metal water piping system shall be bonded as required in 250.104(A) (1), (A)(2), or (A)(3) of this section.

(3) Multiple Buildings or Structures Supplied by a Feeder(s) or Branch Circuit(s). The metal water piping system(s) installed in or attached to a building or structure shall be bonded to any of the following:

(1) Building or structure disconnecting means enclosure where located at the building or structure

(2) Equipment grounding conductor run with the supply conductors

(3) One or more grounding electrodes used The bonding jumper(s) shall be sized in accordance

with Table 250.102(C)(1),

250.102(D) based on the size of the feeder or branch-circuit conductors that supply the building or structure. The bonding jumper shall not be required to be larger than the largest ungrounded feeder or branch-circuit conductor supplying the building or structure.

Reason for Change: New section indicating metal enclosures can be used to connect bonding jumpers or equipment grounding conductors, or both, together to become a part of an effective ground-fault current path.

250.109 Metal Enclosures

250.109 Metal Enclosures Metal enclosures shall be permitted to be used to connect bonding jumpers or equipment grounding conductors, or both, together to become a part of an effective ground-fault current path. Metal covers and metal fittings attached to these metal enclosures shall be considered as being connected to bonding jumpers or equipment grounding conductors, or both.

Reason for Change: New sub-section prohibits the structural metal frame of a building or structure from being used as an equipment grounding conductor.

250.121 Restricted Use of Equipment Grounding Conductors.

250.121 Restricted Use of Equipment Grounding Conductors. The structural metal frame of a building or structure shall not be used as an equipment grounding conductor.

Reason for Change: Revisions clarify that adjustment and/or correction factors do not require an increase in the size of the EGC. New exception was added to allow the EGC to be sized by a qualified person, provided an effective ground fault current path can be established.

250.122 Size of Equipment Grounding Conductors. (B) Increased in Size. If

250.122 Size of Equipment Grounding Conductors. (B) Increased in Size. If Where ungrounded conductors are increased in size

for any reason other than as required in 310.15(B) or 310.15(C) from the minimum size that has sufficient ampacity for the intended installation, wire-type equipment grounding conductors, if where installed, shall be increased in size proportionately,

according to the to the increase in circular mil area of the ungrounded conductors.

Exception: Equipment grounding conductors shall be permitted to be sized by a qualified person to provide an effective ground fault current path in accordance with 250.4(A)(5) or (B)(4).

Reason for Change: Revision clarifies that all wire-type equipment grounding conductors associated with any of those spliced circuit conductors must be connected within the box or to the box.

250.148 Continuity of Equipment Grounding Conductors and Attachment

250.148 Continuity of Equipment Grounding Conductors and Attachment of Equipment Grounding Conductors to in Boxes. If circuit conductors are spliced within a box or terminated on equipment within or supported by a box, all