Chapter 1: Introduction – Advanced Fabricated Building

Building codes are sets of regulations governing the design, construction, alteration, and maintenance of structures. They specify the minimum requirements for adequately safeguarding the health, safety, and welfare of building occupants. For the purposes of this course we will focus on two building codes: (1) the Manufactured Home Construction and Safety Standards or HUD Code (see Figure 1.1) which applies to manufactured homes under a program administered by the US Department of Housing and Urban Development (HUD) under a program administered by the US Department of Housing and Urban Development (HUD), and the (2) the International Residential Code or IRC (see Figure 1.1) which applies to modular buildings (see Figure 1.1). In addition to these two codes that govern the construction of manufactured and modular homes, the Energy Code that spells out the requirements for energy conserving features for the modular home will be covered. The HUD Code includes the energy standards for manufactured homes. In Florida, the Florida Building Code (2017) Energy Conservation specifies the energy standards and requirements for modular homes.

1.1.1 Today’s Major Building Codes

Rather than create and maintain their own codes, most states and local jurisdictions adopt the model building codes maintained by the International Code Council (ICC). In 2000, the three regionally-based model code organizations (BOCA Standard National Code, SBCCI Standard Code, and ICBO Uniform Code) combined together to form the ICC. The ICC family of International Codes includes:

- International Building Code (IBC): applies to all types of new buildings

- International Residential Code (IRC): applies to new one-and two-family dwellings and townhouses of not more than three stories in height

- International Existing Building Code (IEBC): applies to the alteration, repair, or change in occupancy of existing structures.

The ICC publishes new additions of the International Codes every three years and many states and local jurisdictions have adopted them since the first editions were issued in 2000.

Modular homes manufactured in factories are subject to the same regulations and standards as site built homes. The basic difference between inspections of site built homes and manufactured modular homes is that for modular homes, the inspections are conducted by state regulators during the manufacturing process and again after delivery to the site and the installation of the home on its foundation.

Manufactured homes or HUD homes are subject to federal inspections during the in plant manufacturing process and to inspections by the local jurisdiction during the on-site installation process (see Figure 1.2). Manufacturers are held accountable for building homes that are compliant with HUD’s standards by agents of HUD who are referred to as Production Inspection and Primary Inspection Agencies (IPIA). The IPIA is responsible for certifying manufacturing plants before they can begin operations and for routinely inspecting manufacturing in the plants to ensure that they are in compliance with the HUD Code. There are 10 states, including Florida, in which a state agency acts as the IPIA. In the other states where mobile/manufactured home manufacturing occurs, the IPIA is a private company. In Florida, the IPIA is the Bureau of Manufactured Homes/Recreational Vehicle Construction, located in the Division of Motor Vehicles in Tallahassee, Florida.

Figure 1.2 Every mobile/manufactured home must receive a HUD label certifying that it was built in accordance with the Federal Manufactured Housing Construction and Safety Standards (HUD Code). (Source: US Department of Housing and Urban Development)

1.1.2 – Early History of Building Codes

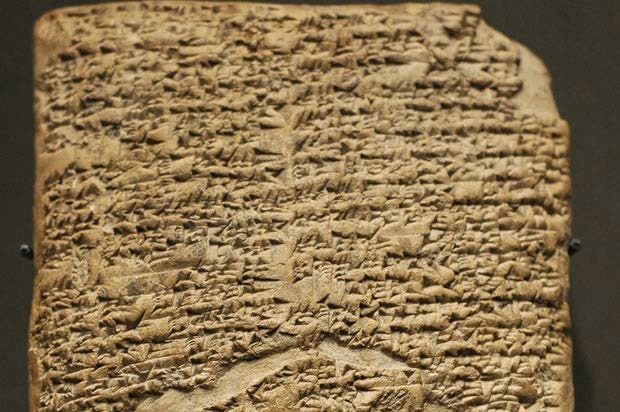

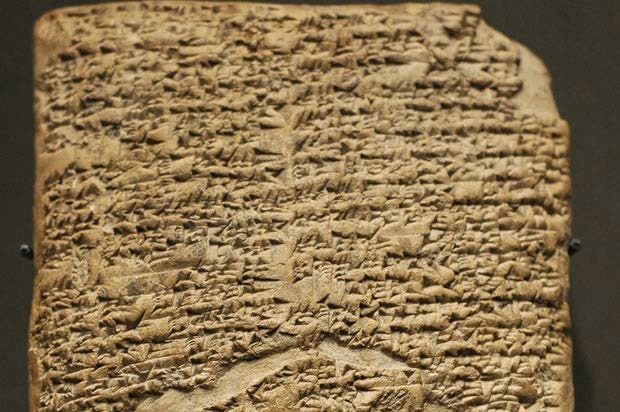

The earliest known written building code was part of the Code of Hammurabi which dates from about 1754 BC. This Code embodied the laws of ancient Mesopotamia and included 282 laws that specify punishments for a wide variety of infractions including harm caused by a poorly constructed home or building. Among the building related provisions in the Code Of Hammurabi are the following (see Figure 1.3):

- If a builder builds a house for someone and completes it, he shall give him a fee of two shekels in money for each “sar” of service. A shekel was the basic monetary unit and it had a weight of 8.33 grams of silver, worth about $32.50 today. Note: A sar is a unit of area that was about 400 square feet in size.

- If a builder builds a house for someone and does not construct it properly, and the house which he builds falls in and kills its owner, then that builder shall be put to death.

- If it kills the son of the owner, the son of that builder shall be put to death.

- If it kills a slave of the owner, then he shall pay slave for slave to the owner of the house.

- If it ruins goods, he shall make compensation for all that has been ruined, and inasmuch as he did not construct the house properly and it collapses, he shall re-erect the house from his own means.

- If a builder builds a house for someone, even though he has not yet completed, if the walls appear to be about to topple, the builder must make the walls solid from his own means.

Figure 1.3 The Code of Hammurabi was the law code of the ancient city of Babylon and copies of the code were etched into man-sized clay tablets for the citizens to read. (Source: Wikipedia Commons)

Mention of code requirements for buildings can be found in the book of Deuteronomy in the Bible in which it is stipulated that parapets must be constructed on all houses to prevent people from falling off. Another mention of building code requirements in the Bible can be found in Leviticus where the methodology on how to treat toxic mold and a system of inspection were established:

On the seventh day the priest shall return to inspect the house. If the mildew has spread on the walls, he is to order that the contaminated stones be torn out and thrown into an unclean place outside the town. He must have all the inside walls of the house scraped and the material that is scraped off dumped into the unclean place outside of town. Then they are to take other stones to replace these and take new clay and plaster the house. If the mildew reappears in the house after the stones have been torn out and the house is scraped and plastered, the priest is to go and examine it and, if the mildew has spread in the house, it is a destructive mildew, the house is unclean. It must be torn down, its stones timbers and all the plaster must be taken out of the town to the unclean place.

In the Middle Ages, the Great Fire of London in 1666 resulted in the first modern era building code, known as the Rebuilding of London Act (see Figure 1.4). The fire destroyed over 13,000 homes plus St Paul’s Cathedral and the result was that over 70,000 residents of London were left homeless. The enormous damage caused by this fire was a result of a combination of a dense built environment, oak timber and tar construction, narrow streets, and primitive fire fighting methods such as the bucket brigades which passed buckets of water from water sources to the fire. The Act required that housing must have some fire resistance and it also regulated the construction of the City of London by, for example, regulating the width of roads.

Figure 1.4 The Great Fire of London in 1666 was the triggering event for the enactment of the first known building codes. (Source: UK Government)

The London Building Act of 1844 was the first real national building standard. It contains provisions such as the thickness of walls, the height of rooms, the materials used in construction, and the placing and design of chimneys, fireplaces, and drains. The Metropolitan Buildings Office was formed to regulate construction throughout London and surveyors were empowered to enforce building regulations.

1.1.3 History of U.S. Building Codes

In early America, George Washington and Thomas Jefferson encouraged the development of building regulations to provide minimum standards that would ensure health and safety. The key events in the evolution of building codes in the United States include the following:

1631 – City of Boston fire prevention ordinance bans wood chimneys and thatch roof coverings.

1678 – City of Boston building laws require slate or tile roofs and brick walls.

1788 – Old Salem (now Winston-Salem, NC) writes first known formal US Building Code.

1844 – The London Building Act of 1844 required drainage improvements, sufficient street widths to ensure adequate ventilation, regulation of explosives, and required inspectors be appointed to supervise the act. The Metropolitan Building Office was established in 1845.

1859 – Baltimore passes its first building code.

1865 – New Orleans enacts a law requiring inspections of public places.

1867 – Due to the large influx of immigrants over the years and barely tolerable living conditions in tenement buildings, the City of New York enacts a “Tenement Housing Act”. This act requires fire escapes and a window for every room.1875 – As a result of the Chicago fire of 1871 the City of Chicago enacts ordinances regulating building construction and fire prevention.

One of the first building modern era building codes, the National Building Code, was developed in 1905 by the Fire Underwriters Association and with the intent that it become a national code. It was directed towards protecting the building rather than the people in the building. National codes that focused on the safety of the occupants (fire exiting, fire alarms, isolation of hazards) were not developed until the 1930’s and 1940’s. The creation of the National Building Code led to the formation of organizations of building officials. By 1940, the United States had three regional code organizations, each with its own code: the BOCA Standard National Code, the SBCCI Standard Code, and the ICBO Uniform Code. As noted earlier, these three organizations and their codes were consolidated into the International Code Council (ICC) and the first set of “I-codes” was published in 2000. These codes include the International Building Code (IBC), the International Residential Code (IRC), the International Energy Conservation Code (IECC), as well as mechanical, plumbing, fire and other codes.

Chapter 1.2: The Manufactured Home Construction and Safety Standard (HUD Code)- Advanced Fabricated Building

In the U.S. a manufactured home (formerly known as a mobile home) must be built to the Manufactured Home Construction and Safety Standards (HUD Code) which was developed in 1976. The U.S. Department of Housing and Urban Development (HUD) began to regulate the construction of mobile/manufactured homes in 1976 pursuant to the provisions of the National Manufactured Housing Construction and Safety Standards Act of 1974. As a consequence of the extensive damage done to manufactured homes by Hurricane Andrew in 1991, HUD amended the Manufactured Housing Construction and Safety Standards in 1994 to provide for greater protection for mobile/manufactured homes from wind damage. During the severe hurricane seasons of 2004 and 2005, no mobile/manufactured home that was built after these new standards went into effect sustained any significant structural damage from the storms.

A manufactured home displays a red certification label on the exterior of each transportable section. Manufactured homes are built in the controlled environment of a manufacturing plant and are transported in one or more sections on a permanent chassis. Manufactured homes are constructed according to a code administered by the U.S. Department of Housing and Urban Development (HUD Code). The HUD Code, unlike conventional building codes, requires manufactured homes to be constructed on a permanent chassis.

1.2.1 HUD Code Definitions

Certification label means the approved form of certification by the manufacturer that is permanently affixed to each transportable section of each manufactured home manufactured for sale in the United States.

Figure 1.5 The Certification Label must be permanently attached to every manufactured home sold in the U.S.

Certification report: the report prepared by an IPIA (see definition below) for each manufactured home manufacturing plant in which the IPIA provides a complete description of the initial comprehensive inspection of the plant, an evaluation of the quality assurance program under the approved quality assurance manual, and the identity of the DAPIA (see definition below) which approved the designs and quality assurance manual used in the plant. Where appropriate the certification report may be made by a DAPIA.

Date of manufacture: the date on which the required label is affixed to the manufactured home.

Defect: a failure to comply with an applicable Federal manufactured home safety and construction standard that renders the manufactured home or any part or component thereof not fit for the ordinary use for which it was intended, but does not result in an unreasonable risk of injury or death to occupants of the affected manufactured home.

Design: drawings, specifications, sketches and the related engineering calculations, tests and data in support of the configurations, structures and systems to be incorporated in manufactured homes manufactured in a plant.

Design Approval PIA (DAPIA): an agency that evaluates and approves or disapproves manufactured home designs and quality control procedures.

Failure to conform: an imminent safety hazard related to the standards, a serious defect, defect, or noncompliance and is used as a substitute for all of those terms.

Federal Manufactured Home Construction and Safety Standard: a reasonable standard for the construction, design, and performance of a manufactured home which meets the needs of the public including the need for quality, durability, and safety. Also referred to as the HUD Code HUD Display Label: Every mobile/manufactured home must receive a HUD label certifying that it was built in accordance with the Federal Manufactured Housing Construction and Safety Standards. The label shall be approximately 2 inches by 4 inches in size and shall be permanently attached to the home by means of 4 blind rivets, drive screws, or other means that render it difficult to remove without defacing it. It shall be etched on 0.32 inches thick aluminum plate. The label number shall be etched or stamped with a 3 letter designation which identifies the Production Inspection and Primary Inspection Agency (IPIA) for the state in which the home is manufactured. Each label shall also be marked with a 6 digit number which the label supplier will furnish. The label shall be located at the tail–light end of each transportable section of the home approximately one foot up from the floor and one foot in from the road side.

Imminent safety hazard: a hazard that presents an imminent and unreasonable risk of death or severe personal injury that may or may not be related to failure to comply with an applicable Federal manufactured home construction or safety standard.

Installations: all arrangements and methods of construction, as well as fire safety, plumbing, heat-producing and electrical systems used in manufactured homes. recognized standards or tests to determine suitable usage in a specified manner.

Label or certification label: the approved form of certification by the manufacturer that is permanently affixed to each transportable section of each manufactured home manufactured for sale to a purchaser in the United States.

Length of a manufactured home: the largest overall length in the traveling mode for a manufactured home, including cabinets and other projections which contain interior space. Length does not include bay windows, roof projections, overhangs, or eaves under which there is no interior space, nor does it include drawbars, couplings or hitches.

Manufactured home: a structure, transportable in one or more sections, which in the traveling mode is 8 body feet or more in width or 40 body feet or more in length or which when erected on-site is 320 or more square feet, and which is built on a permanent chassis and designed to be used as a dwelling with or without a permanent foundation when connected to the required utilities, and includes the plumbing, heating, air-conditioning, and electrical systems contained in the structure. The term does not include any self-propelled recreational vehicle. Calculations used to determine the number of square feet in a structure will include the total of square feet for each transportable section comprising the completed structure and will be based on the structure’s exterior dimensions measured at the largest horizontal projections when erected on site. These dimensions will include all expandable rooms, cabinets, and other projections containing interior space, but do not include bay windows.

Noncompliance: a failure of a manufactured home to comply with a Federal manufactured home construction or safety standard that does not constitute a defect, serious defect, or imminent safety hazard.

Production Inspection PIA (IPIA): an agency that evaluates the ability of manufactured home manufacturing plants to follow approved quality control procedures and provides ongoing surveillance of the manufacturing process.

Quality Assurance Manual: a manual, prepared by each manufacturer for its manufacturing plants and approved by a DAPIA which contains: a statement of the manufacturer’s quality assurance program, a chart of the organization showing, by position, all personnel accountable for quality assurance, a list of tests and test equipment required, a station-by-station description of the manufacturing process, a list of inspections required at each station, and a list by title of personnel in the manufacturer’s organization to be held responsible for each inspection. Where necessary, the quality assurance manual used in a particular plant shall contain information specific to that plant.

Red tag: affixing a notice to a manufactured home which has been found to contain an imminent safety hazard or a failure to conform with any applicable standard. A red tag is the notice so affixed to the manufactured home.

Serious defect: any failure to comply with an applicable Federal manufactured home construction and safety standard that renders the manufactured home or any part thereof not fit for the ordinary use for which it was intended and which results in an unreasonable risk of injury or death to occupants of the affected manufactured home.

Width of a manufactured home: the largest overall width of a manufactured home in the traveling mode, including cabinets and other projections which contain interior space. Width does not include bay windows, roof projections, overhangs, or eaves under which there is no interior space.

1.2.2 Major Provisions of the HUD Code

HUD Wind Zones and Thermal Zones

A HUD home is designed and built to be wind resistant and energy efficient. Wind resistance is provided by metal hurricane straps that connect the roof, walls, and floor together and to the foundation or ground. Homes that will be located in zones with higher winds will have stronger and more robust systems to tie the home to its foundation. For instance, a home located in coastal Louisiana must be more wind-resistant than one in Kentucky.

Similarly, the colder the climate the more insulation and thermal resistance is required for the home envelope. Homes located in Michigan will require higher envelope thermal resistance than homes located in Florida.

The HUD Code specifies wind and thermal resistance requirements based on dividing the U.S. into zones. There are three wind zones and three thermal resistance zones and the division of the country is different for the wind zones compared to the thermal zones. The wind and thermal requirements and their corresponding zones are described in the following sections.

HUD Wind Zones

Each manufactured home must be designed according to the federal HUD Code. The HUD Code stipulate that the home shall be designed and constructed to conform to one of three wind load zones. The higher the number of the Wind Zone, the more stringent are the requirements for wind-resistant construction. The appropriate Wind Zone used in design is dependent on where the home will be initially installed. Homes designed and constructed to a higher Wind Zone can be installed in a lower Wind Zone (a Wind Zone III home can be installed in a Wind Zone I or II location). However, a Wind Zone I home cannot be installed in either a Wind Zone II or III area.

Wind loads are lateral loads that must be resisted by the home. The home must be capable of transferring these imposed lateral loads to the home’s stabilizing devices without exceeding the allowable stresses and other deflection requirements. Wind Zone I, Wind Zone II and Wind Zone III are identified on the basic Wind Zone Map below. The manufactured home producer designs the home to resist the wind load, which is measured in pounds per square foot. Wind Zone I equates to a 70-mph fastest-mile wind speed; Wind Zone II to a 100-mph fastest-mile wind speed; and Wind Zone III to a 110-mph fastest-mile wind speed. Most of the US is in Wind Zone I except for Gulf and Atlantic coastal areas. Wind Zone III is a small area in south Florida that includes Miami and the Florida Keys plus portions of Louisiana.

Figure 1.6 There are three Wind Zones in the HUD Code, with Wind Zone III designating the highest wind velocities. The higher the Wind Zone, the more stringent are the requirements for connecting the home and it components together and to the ground.

HUD Thermal Zones

In addition to the Wind Zones, HUD specifies three Thermal Zones that designate varying levels of thermal resistance for the home envelope. The higher the Thermal Zone number, the more thermal resistance or insulation is required. The Thermal Zones are shown below together with the minimum required Uo value. Uo indicates how much resistance the wall, window, or roof must have to energy flows between the outside and home interior. The lower the Uo value the more thermal resistance the envelope must have. The further north the home will be installed, the lower the Uo value must be to provide adequate thermal resistance for the purpose or reducing energy consumption and cost. In simple terms, a lower Uo value indicates the home envelope has more insulation. Note that a higher number Wind Zone has a lower Uo value.

Figure 1.7 The HUD Code requires more insulation and thermal resistance for homes in the colder northern U.S. compared to the south. Thermal Zone 3 is the most stringent area and requires the most insulation due to the large temperature differences that occur between inside and outside the home. The Uo value is a measure of thermal resistance and a lower number indicates more resistance.

The appropriate Thermal Zone value used in design is dependent on where the home will be initially installed. Homes designed and constructed to a higher Thermal Zone can be installed in a lower Thermal Zone (a home designed to a Thermal Zone 3 can be installed in a Thermal Zone 1 or 2). However, a Thermal Zone 1 home cannot be installed in either a Thermal Zone 2 or 3 area.

The Uo value is the overall coefficient of heat transmission of the manufactured home based on the respective thermal zone location and an indoor design temperature of 70 oF, and is defined in units of BTU/(hour)(square foot)(oF). The overall Uo value for the home thermal envelope design must not exceed the values as shown on the above map. The design Uo value for Thermal Zone 1 is 0.116 BTU/hr·ft2·oF, for Thermal Zone 2 is 0.096 BTU/ hr·ft2·oF, and for Thermal Zone 3 is 0.079 BTU/ hr·ft2·oF. Again, the lower the Uo value, the greater the thickness of insulation that is required.

1.2.2.2 Major HUD Code Requirements

1.2.2.2.1 Lighting and Ventilation

Lighting. Each habitable room shall be provided with exterior windows and/or doors having a total glazed area of not less than 8 percent of the gross floor area.

- Kitchens, bathrooms, toilet compartments, laundry areas, and utility rooms may be provided with artificial light in place of

- Rooms and areas may be combined for the purpose of providing the required natural lighting provided that at least one half of the common wall area is open and unobstructed, and the open area is at least equal to 10 percent of the combined floor area or 25 square feet whichever is greater.

Whole-house ventilation. Each manufactured home must be provided with whole-house ventilation having a minimum capacity of 0.035 cubic feet per minute (cfm)/ft2 of interior floor space or its hourly average equivalent. This ventilation capacity must be in addition to any openable window area. In no case shall the installed ventilation capacity of the system be less than 50 cfm nor more than 90 cfm.

- The ventilation capacity must be provided by a mechanical system or a combination passive and mechanical system. Mechanical means fan powered and passive refers to ventilation cby air flow that is caused by natural forces such as the chimney effect in which air rises due to warming. Passive implies a fan is not being used. A combination passive and mechanical system can operate in either

- The ventilation system or provisions must exchange air directly with the exterior of the home, except that the ventilation system must not draw or expel air from or to the space underneath the home. The ventilation system must not draw or expel air into the floor, wall, or ceiling/roof systems, even if those systems are vented. The ventilation system must be designed to ensure that outside air is distributed to all bedrooms and main living areas. The combined use of undercut doors or transom grills connecting those areas to the room where the mechanical system is located meets this requirement.

- The ventilation system or a portion of the system is permitted to be integral with the home’s heating or cooling system. The system must be capable of operating independently of the heating or cooling modes. A ventilation system that is integral with the heating or cooling system is to be listed as part of the heating and cooling system or listed as suitable for use with that

- A mechanical ventilation system, or mechanical portion thereof, must be provided with a manual control, and must be permitted to be provided with automatic timers or

- A whole-house ventilation label must be attached to the whole-house ventilation control, must be permanent, and must state: ‘‘WHOLE-HOUSE ’’

Additional ventilation.

- At least half of the minimum required glazed area in paragraph (a) above shall be openable directly to the outside of the manufactured home for unobstructed

- Kitchens shall be provided with a mechanical ventilation system that is capable of exhausting 100 cfm to the outside of the home. The exhaust fan shall be located as close as possible to the range or cook top, but in no case farther than 10 feet horizontally from the range or cook

- Each bathroom and separate toilet compartment shall be provided with a mechanical ventilation system capable of exhausting 50 cfm to the outside of the home. A separate toilet compartment may be provided with 1.5 square feet of openable glazed area in place of mechanical ventilation, except in Uo value Zone

1.2.2.2.2 Exit Facilities and Exterior Doors.

Number and location of exterior doors. Manufactured homes shall have a minimum of two exterior doors located remote from each other.

- Required egress doors shall not be located in rooms where a lockable interior door must be used in order to

- In order for exit doors to be considered remote from each other, they must comply with all of the following:

- Both of the required doors must not be in the same room or in group of rooms which are not defined by fixed

- Single wide units: Doors may not be less than 12 ft. from each other as measured in any straight line direction regardless of the length of path of travel between

- Double wide units: Doors may not be less than 20 ft. from each other as measured in any straight line direction regardless of the length of path of travel between

- One of the required exit doors must be accessible from the doorway of each bedroom without traveling more than 35

1.2.2.2.3 Egress Windows and Devices.

- Every room designed expressly for sleeping purposes, unless it has an exit door, shall have at least one outside window or approved exit

- The bottom of the window opening shall not be more than 36 inches above the

- Locks, latches, operating handles, tabs, and any other window screen or storm window devices which need to be operated in order to permit exiting, shall not be located in excess of 54 inches from the finished

- Integral rolled-in screens shall not be permitted in an egress window unless the window is of the hinged

1.2.2.2.4 Room Requirements.

- Every manufactured home shall have at least one living area with not less than 150 sq. ft. of gross floor area.

- Rooms designed for sleeping purposes shall have a minimum gross square foot floor area as follows:

- All bedrooms shall have at least 50 sq. ft. of floor

- Bedrooms designed for two or more people shall have 70 sq. ft. of floor area plus 50 sq. ft. for each person in excess of

- Every room designed for sleeping purposes shall have accessible clothes hanging space with a minimum inside depth of 22 inches and shall be equipped with a rod and

1.2.2.2.5 Toilet Compartments.

Each toilet compartment shall be a minimum of 30 inches in width, except, when the toilet is located adjacent to the short dimension of the tub, the distance from the tub to the center line of the toilet shall not be less than 12 inches. At least 21 inches of clear space shall be provided in front of each toilet.

1.2.2.2.6 Hallways.

Hallways shall have a minimum horizontal dimension of 28 inches measured from the interior finished surface to the interior finished surface of the opposite wall. When appliances are installed in a laundry area, the measurement shall be from the front of the appliance to the opposite finished interior surface. When appliances are not installed and a laundry area is provided, the area shall have a minimum clear depth of 27 inches in addition to the 28 inches required for passage. In addition, a notice of the available clearance for washer/dryer units shall be posted in the laundry area. Minor protrusions into the minimum hallway width by doorknobs, trim, smoke alarms or light fixtures are permitted.

1.2.2.2.7 Glass and glazed openings.

Windows and sliding glass doors. All windows and sliding glass doors shall meet the requirements of the ‘‘Standard for Windows and Sliding Glass Doors Used in Manufactured Homes’’.

Safety glazing. Glazing in all entrance or exit doors, sliding glass doors, units (fixed or moving sections), unframed glass doors, unbacked mirrored wardrobe doors (i.e., mirrors not secured to a backing capable of being the door itself), shower and bathtub enclosures and surrounds to a height of 6 feet above the bathroom floor level, storm doors or combination doors, and in panels located within 12 inches on either side of exit or entrance doors shall be of a safety glazing material. Safety glazing material is considered to be any glazing material capable of passing the requirements of the governing standards.

1.2.2.2.8 Fire Safety and Flame Spread Requirements

Materials are rated with respect to their fire safety by the Flame Spread Index. The Flame Spread Rating is a ranking derived by laboratory standard test methodology of a material’s propensity to burn rapidly and spread flames. The higher the Flame Spread Index the more rapidly that flames will burn across the material surface. In general, the National Fire Protection Association defines three classes of materials depending on their Flame Spread Index:

| Class | Flame Spread Index |

| A | 0-25 |

| B | 26-75 |

| C | 76-200 |

The interior finish of all walls, columns, and partitions must not have a Flame Spread Index exceeding 200 except as otherwise specified herein. Ceiling interior finish must not have a Flame Spread Index exceeding 75. Walls adjacent to or enclosing a furnace or water heater and ceilings above them must have an interior finish with a Flame Spread Index not exceeding 25. Exposed interior finishes adjacent to the cooking range shall have a Flame Spread Index not exceeding 50. The HUD Code spells out the Flame Spread Index requirements for all elements of the home. Note that the terminology, Flame Spread Index and flame spread rating are used interchangeably.

Smoke alarm requirements.

- Each smoke alarm required must bear a label with evidence of conformance with HUD requirements

- Required smoke alarm locations. At least one smoke alarm must be installed in each of the following locations:

- To protect both the living area and kitchen space. Manufacturers are encouraged to locate the alarm in the living area remote from the kitchen and cooking appliances. A smoke alarm located within 20 feet horizontally of a cooking appliance must incorporate a temporary silencing feature or be of a photoelectric

- In each room designed for

- On the ceiling of the upper level near the top or above each stairway, other than a basement stairway in any multistory home. The alarm must be located so that smoke rising in the stairway cannot be prevented from reaching the alarm by an intervening door or obstruction

1.2.2.2.9 Structural design requirements.

General. Each manufactured home shall be designed and constructed as a completely integrated structure capable of sustaining the design load requirements of this standard, and shall be capable of transmitting these loads to stabilizing devices without exceeding the allowable stresses or deflections. Roof framing shall be securely fastened to wall framing, walls to floor, and the floor to the chassis.

Fastening of structural systems.

Roof framing must be securely fastened to wall framing, walls to floor structure, and floor structure to chassis, to secure and maintain continuity between the floor and chassis in order to resist wind overturning, uplift, and sliding, and to provide continuous load paths for these forces to the foundation or anchorage system. The number and type of fasteners used must be capable of transferring all forces between elements being joined.

Walls.

The walls shall be of sufficient strength to withstand the load requirements. The connections between the bearing walls, floor, and roof framework members shall be fabricated in such a manner as to provide support for the material used to enclose the manufactured home and to provide for transfer of all lateral and vertical loads to the floor and chassis.

Floors.

- Floor assemblies shall be designed in accordance with accepted engineering practice standards to support a minimum uniform live load of 40 lb/ft2 plus the dead load of the materials. In addition (but not simultaneously), floors shall be able to support a 200–pound concentrated load on a one-inch diameter disc at the most critical location with a maximum deflection not to exceed one-eighth inch relative to floor framing.

- Wood, wood fiber or plywood floors or subfloors in kitchens, bathrooms (including toilet compartments), laundry areas, water heater compartments, and any other areas subject to excessive moisture shall be moisture resistant or shall be made moisture resistant by sealing or by an overlay of nonabsorbent material applied with water-resistant adhesive.

Roofs.

- Roofs shall be of sufficient strength to withstand the load requirements. The connections between roof framework members and bearing walls shall be fabricated in such a manner to provide for the transfer of design vertical and horizontal loads to the bearing walls and to resist uplift forces.

- Roofing membranes shall be of sufficient rigidity to prevent deflection which would permit ponding of water or separation of seams due to wind, snow, ice, erection or transportation forces.

- Cutting of roof framework members for passage of electrical, plumbing or mechanical systems shall not be allowed except where substantiated by engineering

- All roof penetrations for electrical, plumbing or mechanical systems shall be properly flashed and sealed. In addition, where a metal roof membrane is penetrated, a wood backer shall be installed. The backer plate shall be not less than 5⁄16 inch plywood, with exterior glues, secured to the roof framing system beneath the metal

Windstorm protection.

Each manufactured home shall have provisions for support/anchoring or foundation systems that, when properly designed and installed, will resist overturning and lateral movement (sliding) of the manufactured home as imposed by the respective design loads.

Anchoring Systems.

- The provisions of this section shall be followed and the support and anchoring systems shall be designed by a Registered Professional Engineer or

- The manufacturer of each manufactured home is required to make provision for the support and anchoring systems but is not required to provide the anchoring equipment or stabilizing devices.

- For anchoring systems, the instructions provided by the Engineer or Architect shall indicate:

- The minimum anchor capacity required;

- That anchors should be certified by a professional engineer, architect, or a nationally recognized testing laboratory as to their resistance;

- That ground anchors should be embedded below the frost line and be at least 12 inches above the water table; and

- That ground anchors should be installed to their full depth, and stabilizer plates should be installed to provide added resistance to overturning or sliding

- Anchoring equipment should be certified by a registered professional engineer or architect to resist these specified forces in accordance with testing procedures in ASTM Standard

1.2.2.2.10 thermal protection

Ceiling vapor retarders.

- In Thermal Zones 2 and 3, ceilings must have a vapor retarder installed on the living space side of the roof cavity.

- For manufactured homes designed for Thermal Value Zone 1, the vapor retarder may be omitted.

Exterior wall vapor retarders.

- Exterior walls must have a vapor retarder installed on the living space side of the wall; or

- Unventilated wall cavities must have an external covering and/or sheathing that forms the pressure envelope. Formed exterior siding applied in sections with joints not caulked or sealed, are not considered to restrict water vapor transmission; or

Air infiltration.

The opaque envelope shall be designed and constructed to limit air infiltration to the living area of the home. Any design, material, method or combination that accomplishes this goal may be used. The goal of the infiltration control criteria is to reduce heat loss/heat gain due to infiltration as much as possible without impinging on health and comfort and within the limits of reasonable economics.

- Envelope penetrations. Plumbing, mechanical and electrical penetrations of the pressure envelope, and installations of window and door frames shall be constructed or treated to limit air infiltration. Penetrations of the pressure envelope made by electrical equipment, other than distribution panel boards and cable and conduit penetrations, are exempt from this requirement. Cable penetrations through outlet boxes are considered exempt.

- Joints between major envelope elements. Joints not designed to limit air infiltration between wall-to-wall, wall-to- ceiling and wall-to-floor connections shall be caulked or otherwise sealed. When walls are constructed to form a pressure envelope on the outside of the wall cavity, they are deemed to meet this requirement.

1.2.2.3 Plumbing Systems

1.2.2.3.1 General requirements

Any plumbing system installed in a manufactured home shall conform, at least, with the provisions of this subpart.

- General. The plumbing system shall be of durable material, free from defective workmanship, and so designed and constructed as to give satisfactory service for a reasonable life expectancy.

- Conservation. Water closets shall be selected and adjusted to use the minimum quantity of water consistent with proper performance and cleaning.

- Connection to drainage system. All plumbing, fixtures, drains, appurtenances, and appliances designed or used to receive or discharge liquid waste or sewage shall be connected to the manufactured home drainage system in a manner provided by this

- Workmanship. All design, construction, and workmanship shall be in conformance with accepted engineering practices and shall be of such character as to secure the results sought to be obtained by this standard.

- Components. Plumbing materials, devices, fixtures, fittings, equipment, appliances, appurtenance, and accessories intended for use in or attached to a manufactured home shall conform to applicable standards.

1.2.2.3.2 Water distribution systems.

- Supply piping. Piping systems shall be sized to provide an adequate quantity of water to each plumbing fixture at a flow rate sufficient to keep the fixture in a clean and sanitary condition without any danger of backflow or siphonage. The manufacturer shall include in his written installation instructions that the manufactured home has been designed for an inlet water pressure of 80 psi, and a statement that when the manufactured home is to be installed in areas where the water pressure exceeds 80 psi, a pressure reducing valve should be installed.

- Hot water supply. Each manufactured home equipped with a kitchen sink, and bathtub and/or shower shall be provided with a hot water supply system including a listed water

1.2.2.3.3 Drainage systems.

- Each fixture directly connected to the drainage system shall be installed with a water seal trap.

- The drainage system shall be designed to provide an adequate circulation of air in all piping with no danger of siphonage, aspiration, or forcing of trap seals under conditions of ordinary use.

- Materials

- Drainage piping shall be standard weight steel, wrought iron, brass, copper tube DWV, listed plastic, cast iron, or other listed or approved materials.

- Drainage fittings shall be recessed drainage pattern with smooth interior waterways of the same diameter as the piping and shall be of a material conforming to the type of piping used. Drainage fittings shall be designed to provide for a 1⁄4 inch per foot grade in horizontal piping.

1.2.2.3.4 Heating, Cooling, and Fuel Burning Systems

Heating, cooling and fuel burning appliances and systems in manufactured homes shall be free of defects, and shall conform to applicable standards in the following table unless otherwise specified in this standard.

1.2.2.3.5 Gas piping systems.

General. The requirements of this section shall govern the installation of all fuel gas piping attached to any manufactured home. The gas piping supply system shall be designed for a pressure not exceeding 14 inch water column (1⁄2 psi) and not less than 7 inch water column (1⁄4 psi). The manufacturer shall indicate in his written installation instructions the design pressure limitations for safe and effective operation of the gas piping system. None of the requirements listed in this section shall apply to the piping supplied as a part of an appliance. All exterior openings around piping, ducts, plenums or vents shall be sealed to resist the entrance of rodents.

Materials. All materials used for the installation, extension, alteration, or repair of any gas piping system shall be new and free from defects or internal obstructions. It shall not be permissible to repair defects in gas piping or fittings. Inferior or defective materials shall be removed and replaced with acceptable material. The system shall be made of materials having a melting point of not less than 1,450 F.

1.2.2.3.6 Heat producing appliances.

- Heat-producing appliances and vents, roof jacks and chimneys necessary for their installation in manufactured homes shall be listed or certified by a nationally recognized testing agency for use in manufactured

- A manufactured home shall be provided with a comfort heating

- When a manufactured home is manufactured to contain a heating appliance, the heating appliance shall be installed by the manufacturer of the manufactured home in compliance with applicable sections of this

- When a manufactured home is manufactured for field application of an external heating or combination heating/cooling appliance, preparation of the manufactured home for this external application shall comply

1.2.2.3.7 Exhaust duct system and provisions for the future installation of a clothes dryer.

All gas and electric clothes dryers shall be exhausted to the outside by a moisture-lint exhaust duct and termination fitting. When the clothes dryer is supplied by the manufacturer, the exhaust duct and termination fittings shall be completely installed by the manufacturer. However, if the exhaust duct system is subject to damage during transportation, it need not be completely installed at the factory when:

- The exhaust duct system is connected to the clothes dryer, and

- A moisture lint exhaust duct system is roughed in and installation instructions are provided.

- A clothes dryer moisture-lint exhaust duct shall not be connected to any other duct, vent or chimney.

- The exhaust duct shall not terminate beneath the manufactured

- Moisture-lint exhaust ducts shall not be connected with sheet metal screws or other fastening devices which extend into the interior of the

- Moisture-lint exhaust duct and termination fittings shall be installed in accordance with the appliance manufacturer’s printed

1.2.2.3.8 Appliances, cooling.

Every air conditioning unit or a combination air conditioning and heating unit shall be listed or certified by a nationally recognized testing agency for the application for which the unit is intended and installed in accordance with the terms of its listing.

1.2.2.3.9 Circulating air systems.

Supply ducts and any dampers contained therein shall be made from galvanized steel, tin- plated steel, or aluminum. A duct system integral with the structure shall be of durable construction that can be demonstrated to be equally resistant to fire and deterioration.

1.2.2.4 Electrical Systems

- The National Electrical Code, and specifically Article 550 of the National Electrical Code (NFPA No. 70–2005), plus the HUD Code address the electrical conductors and equipment installed within or on manufactured homes and the conductors that connect manufactured homes to a supply of

- The provisions of the HUD Code apply to manufactured homes intended for connection to a wiring system nominally rated 120/240 volts, 3-wire AC, with grounded

- All electrical materials, devices, appliances, fittings and other equipment shall be listed or labeled by a nationally recognized testing agency and shall be connected in an approved manner when in

- Aluminum conductors, aluminum alloy conductors, and aluminum core conductors such as copper clad aluminum; are not acceptable for use in branch circuit wiring in manufactured homes.

1.2.2.4.1 Power supply.

The power supply to the manufactured home shall be a feeder assembly consisting of not more than one listed 50 ampere manufactured home power supply cords, or a permanently installed circuit. A manufactured home that is factory-equipped with gas or oil-fired central heating equipment and cooking appliances shall be permitted to be provided with a listed manufactured home power-supply cord rated 40 amperes.

1.2.2.4.2 Disconnecting means and branch-circuit protective equipment.

- The branch-circuit equipment is permitted to be combined with the disconnecting means as a single assembly. Such a combination is permitted to be designated as a distribution panelboard. If a fused distribution panelboard is used, the maximum fuse size of the mains must be plainly marked with lettering at least 1⁄4-inch high and that is visible when fuses are changed.

- Plug fuses and fuseholders shall be tamper-resistant, Type ‘‘S,’’ enclosed in dead-front fuse panelboards. Electrical distribution panels containing circuit breakers shall also be dead-front type.

- A single disconnecting means shall be provided in each manufactured home consisting of a circuit breaker, or a switch and fuses and their accessories installed in a readily accessible location near the point of entrance of the supply cord or conductors into the manufactured home. The main circuit breakers or fuses shall be plainly marked ‘‘Main.’’ This equipment shall contain a solderless type of grounding connector or bar for the purposes of grounding with sufficient terminals for all grounding conductors. The neutral bar termination of the grounded circuit conductors shall be insulated.

1.2.2.4.3 Grounding.

- General. Grounding of both electrical and nonelectrical metal parts in a manufactured home shall be through connection to a grounding bus in the manufactured home distribution panelboard. The grounding bus shall be grounded through the green-colored conductor in the supply cord or the feeder wiring to the service ground in the service-entrance equipment located adjacent to the manufactured home location. Neither the frame of the manufactured home nor the frame of any appliance shall be connected to the neutral conductor in the manufactured home.

- Insulated neutral. The grounded circuit conductor (neutral) shall be insulated from the grounding conductors and from equipment enclosures and other grounded parts. The grounded (neutral) circuit terminals in the distribution panelboard and in ranges, clothes dryers, counter-mounted cooking units, and wall-mounted ovens shall be insulated from the equipment enclosure.

Chapter 1.3: The Florida Building Code – Advanced Fabricated Building

The Florida Building Code is patterned after the International Construction Code but has modifications, additions and deletions that are specific to Florida. The Florida Building replaced Florida’s patchwork of codes and regulations that were developed, amended, administered, and enforced by more than 400 local jurisdictions and state agencies with building code regulation responsibilities. The current Code is a single statewide code based on national model codes and consensus standards, amended for Florida specific needs for the design and construction of buildings. The Code is designed to make the local building process more efficient, increase accountability, bring new and safer products to the market, increase consumer confidence, and better protect the residents of Florida.

The base codes for the sixth Edition (2017) of the Florida Building Code Residential is the International Residential Code, 2015 edition; the National Electrical Code, 2014 edition; plus substantive criteria from the American Society of Heating, Refrigerating and Air-Conditioning Engineers’ (ASHRAE) Standard 90.1-2013. State and local codes adopted and incorporated into the code include the Florida Building Code, Accessibility, and special hurricane protection standards for the High-Velocity Hurricane Zone.

The Florida Building Code is adopted and updated with new editions every three years by the Florida Building Commission. It is amended annually to incorporate interpretations, clarifications and to update standards. Minimum requirements for permitting, plans review and inspections are established by the Code, and local jurisdictions may adopt additional administrative requirements that are more stringent.

The purpose of this module is to provide an understanding of the basic minimum home building requirements as outlined by the international building code, and the importance of adhering to minimum code requirements. The module includes the following sections:

- The permitting and inspection process

- Building planning and construction requirements

- The means of egress system

- Minimum mechanical and plumbing requirements

1.3.1 Permits and Inspections

1.3.3.1 Permit Application:

The code-enforcement process is normally initiated by an application for a permit to construct or remodel a building. In the state of Florida, a permit is required for any owner or authorized agent who intends to construct, enlarge, alter, repair, move, demolish, or change the occupancy of a building or structure, or to erect, install, enlarge, alter, repair, remove, convert or replace any required impact-resistant coverings, electrical, gas, mechanical or plumbing system, the installation of which is regulated by code, or to cause any such work to be done.

To obtain a building permit one must first make an application with the building official, by filing an application in writing on a form furnished by the building department. Each application will have the date of application, and the building code version that is in effect as of that date. The building official is responsible for processing applications and issuing permits.

1.3.1.2 Application Requirements:

An application for a permit is good for 180 days after the date of filing. The building official can grant one or more extensions for no more than 90 days each as long as the extension is requested in writing and has justifiable cause. As a condition to receiving a permit, the applicant must show proof that workers’ compensation coverage has been provided for employees and contractors have the required licenses.

Additionally, the Florida Building Code requires that the permit applicant can adequately demonstrate that construction for the proposed project complies with the code. This is primarily accomplished by submitting construction documents for the project along with the application for permit.

Construction Documents:

Within the construction documents each official is looking for sufficient clarity and detail of the location, nature and extent of the work proposed, as well as conformance to the provisions of the building code. Specifically, construction documents need to be prepared by a design professional and affixed with their seal as required by Florida law; and they should be dimensioned and drawn upon suitable material.

Review of construction documents by the building official shall include the following minimum criteria and documents: a floor plan; site plan; foundation plan; floor and roof framing plan or truss layout; and all exterior elevations.

Once the construction documents are reviewed, approved and stamped as “Reviewed for Code Compliance”, one set is kept by the building official, the other set is returned to the applicant to be kept at the job site, and the building permit is issued. Even after the permit is issued, the building official can inspect the approved plans for errors or code violations and require corrections as such. Work done should be in accordance with the approved construction drawings, any changes made during construction which deviate from the approved drawings, need to be resubmitted for approval as an amended set of documents.

1.3.1.5 Permit Longevity:

A permit becomes null and void after 6 months if the work has not been started or if the work was started but is suspended or abandoned for a period of 6 months. Lack of at least one approved inspection within 180 days of permit issuance will serve as a validation that the job has been suspended or abandoned. Once the permit has been issued, a copy must be kept on the jobsite until completion of the project. The building permit and inspection card must be in plain view on

1.3.1.5 Inspections:

Work that requires a permit is also subject to inspections by the building official. A list of required inspections is located on the bottom of the permit placard. Instructions on scheduling inspections are provided when the permit is issued. It is the applicant’s responsibility to ensure that all required inspections are made prior to proceeding with work beyond each successive point.

Upon notification from the permit holder, the building official makes these inspections. However, the timing and sequencing of when these inspections occur and what elements are inspected is up to the building official.

If the work passes inspection, then the official will release that portion of the construction, if not, the permit holder will be informed of violations which must be corrected to comply with applicable codes and to proceed with work.

For new dwellings, once all fees are paid and all required inspections are passed and completed, the applicant will be issued a Certificate of Occupancy (commonly called a CO).

1.3.2 Building Planning and Construction

1.3.2.1 Building Planning

It is important for design and construction professionals to adhere to basic standards for building a home, starting with the structural frame. Strengthening the structural frame of a house includes creating a “complete load path” within the home, which is a method of construction that uses a system of wood, metal connectors, fasteners (like nails and screws) and shear walls to connect the structural frame of the house together. A complete load path is like a chain that ties the house together from the roof to the foundation. A home is more likely to withstand a seismic or high wind event and stay intact when all parts of the house – roof, walls, floors and foundation – are connected together securely.

The Florida Building Code requires all buildings and structures, and all parts thereof, to be constructed in a way that safely support all loads, including dead loads, live loads, roof loads, flood loads and wind loads. And a continuous load path between foundations, walls, & roofs must be provided. (FBC- Residential R501.2 Requirements and R601.2 Requirements)

1.3.2.2 Florida Building Code Loads

Dead Loads – The weight of materials of construction incorporated into the building, including walls, floors, roofs, ceilings, stairways, finishes, cladding and other architectural or structural items, and the weight of fixed service equipment such as cranes, plumbing stacks and risers, electrical feeders, heating, ventilating and air-conditioning systems and fire sprinkler systems.

Live Loads – Those loads produced by the use and occupancy of the building or other structure and do not include construction or environmental loads such as wind load, snow load, rain load, earthquake load, flood load or dead load.

Live Loads (Roof) – Those loads produced (1) during maintenance by workers, equipment and materials; and (2) during the life of the structure by movable objects such as planters and by people.

Nominal Loads – The magnitudes of other design loads including soil, wind, snow, rain, flood and earthquake.

Constructing homes in accordance with the provisions of the code should result in a system that provides a complete load path, which will transfer of all loads from their point of origin through the load-resisting elements to the foundation.

1.3.2.3 Exterior Walls

Exterior walls of the house must create a weather-resistant exterior wall envelope and include corrosion-resistant flashing. One purpose of the wall envelope is to prevent the accumulation of water within the wall assembly. One way it can be accomplished is by using weather- resistant sheathing paper such as No. 15 asphalt felt or other approved water-resistive barrier over studs or sheathing of all exterior walls. Concrete and masonry walls properly constructed and flashed in accordance with code specifications do not require a weather-resistant exterior wall envelope.

1.3.2.4 Interior Wall Coverings

Interior coverings and finishes must be installed as required by the code which outlines the minimum thickness for plaster, gypsum plaster proportions, maximum volume aggregate per volume of cementitious material for Portland cement plaster, and minimum thickness for gypsum drywall. Interior finishes and materials must comply with the flame spread and smoke- development requirements which state that wall and ceiling finishes shall have a flame-spread classification of no greater than 200 and a smoke-developed index of no greater than 450.

1.3.2.5 Minimum Room Dimensions

The total area of a residence is generally not regulated by code; however, a structure more than three stories in height would have to meet the provisions of the Florida Building Code- Building, rather than the Florida Residential Code. Only homes three stories or less, with a separate means of egress for accessory structures (like a garage or carport) fall under the provisions of the Residential Code. The Code does, however, have several minimum requirements that apply to residences. Residential space standards provide specifications for the internal floor area of dwellings and rooms.

Every dwelling must have at least one habitable room that has a minimum of 120 square feet of gross floor area. In most cases, this larger room is designed as the living area in a home. Other habitable rooms must have a floor area of at least 70 square feet and cannot have any one wall less than 7 feet in length.

The kitchen, however, though still considered a habitable room, can be a little smaller, but not less than 50 square feet in gross floor area. A habitable room is defined as all rooms used for living, dining, sleeping and cooking purposes. Bathrooms, closets, halls, and utility spaces are not considered habitable rooms.

When figuring the square footage of a room, any portions of the room with a sloped ceiling measuring less than 5 feet or a furred ceiling measuring less than 7 feet from the finished floor to the finished ceiling are not included as habitable space for the room.

The home designer has the flexibility to distribute the total amount of space among the rooms as they wish, as long as the combined spaces and the individual rooms meet minimum code requirements.

1.3.2.6 Ceiling Heights and Insulation

Habitable space, hallways, bathrooms, toilet rooms, laundry rooms, and portions of basements containing these spaces cannot have a ceiling less than 7 feet.

There are some exceptions to that provision:

- Rooms with sloped ceilings need to have a ceiling height of at least 7 feet in no less than 50% of the required floor area of the room, and no portion of the required floor area can have a ceiling height of less than 5

- The ceiling in a bathroom must be at least 6 feet 8 inches over bathroom fixtures as well as at the center of the clearance area in front of the fixtures, which ranges from 21” to 24” depending on the fixture type. In a shower or tub area with a showerhead, there are minimum space requirements, which include a 30 inch x 30 inch area at the showerhead and a ceiling height of no less than 6 feet 8 inches

The code further specifies that ceilings in basements without habitable space, hallways, bathrooms, toilet rooms and laundry rooms can be as low as 6 feet 8 inches in height, and beams, ducts, or other obstructions may project to within 6 feet 4 inches of the finished floor.

Often people renovate an attic to increase their home’s resale value but spaces with a ceiling height of less than 7 feet don’t contribute to a home’s square footage in terms of appraisal.

Insulation materials must have a flame spread index not to exceed 25 with an accompanying smoke-developed index not to exceed 450.

1.3.2.7 Garages

The relationship between the garage and the habitable spaces of the home, require special attention and detailing. In order to prevent carbon monoxide or fumes from other hazardous materials stored in the garage from entering the house, openings from the garage leading directly into a bedroom space are not permitted by the Florida Building Code. Other openings between the garage and residence shall be equipped with either a solid wood door, solid, or honeycomb core steel door, none of which can be less than 1 3/8” thick, or you can use a 20- minute fire-rated door. The garage must be separated from the home interior and attic area by a minimum of ½” thick gypsum board applied to the garage side.

Garages situated beneath habitable rooms require a separation of at least 5/8” Type X gypsum board or equivalent.

There are two types of gypsum wallboard, regular and type X. Type X wallboard is formulated by adding noncombustible fibers to the gypsum. These fibers help maintain the integrity of the core as shrinkage occurs, providing greater resistance to heat transfer during fire exposure. Type X gypsum is typically required to achieve required fire resistance ratings.

1.3.2.8 Detached Garages and Carports:

Detached garages on the same lot as a house but located less than 3 feet away from it, require at least ½” gypsum board applied to the interior side of exterior wall that faces the home, this extra protection is not required on the garage walls perpendicular to the house.

There should be no opening for air duct systems into the garage, such as returns or vents. These might actually “fuel” a fire. Any ducts passing through the garage or penetrating the separating wall or ceiling are required to be a minimum of 26-gauge sheet steel, 1 inch minimum rigid nonmetallic Class 0 or Class 1 duct board, or other approved material.

Garage floors are required to be of an approved noncombustible material, and should be sloped to facilitate the movement of liquids either to a drain or toward the main vehicle entry.

Carports need to be open on at least two sides, and have approved noncombustible floor material. Ground level carports can have asphalt surfaces. If a carport is not open on at least two sides, it’s considered to be a garage according to code, and must meet the minimum provisions for garages.

1.3.3 Means of Egress and Emergency Openings

1.3.3.1 Means of Egress

The Florida Building Code defines “means of egress” as a travel system that provides a continuous, unobstructed and undiminished path from an occupied point in a building or structure to a public way.

A means of egress is required by the building code to provide a point of emergency escape and rescue. The term “egress” is used in most building codes to specify areas of access or exits, typically doors, windows, and hallways. The phrase “means of egress” refers to the ability to exit the structure, primarily in the event of an emergency, such as a fire.

A means of egress comprised of three distinct parts: the path of travel to an exit, the exit itself, and the exit discharge (the path to a safe area outside).

Here are definitions of these terms, as well as some other important definitions for understanding the means of egress system.

1.3.3.2 Definition of Means of Egress Terms

- EXIT ACCESS: The portion of a means of egress system that leads you from occupied space to an exit. It includes any room or space occupied by a person and any doorway, aisle, corridor, stair, or ramp traveled on the way to the

- EXIT: The portion of a means of egress system that is between the exit access and the exit discharge or public way. This area is separated from other interior spaces by fire- resistance-rated construction and opening protectives as required. It can be very basic, such as an exterior door, or it can include enclosed stairwells and ramps. In some special cases, it can include exit corridors or passageways. The building materials used for an exit require higher fire ratings than the materials for exit

- EXIT DISCHARGE: The portion of a means of egress system between the termination of an exit and the public way. It can be inside a building such as the main lobby, or outside a building such as an exterior vestibule, courtyard, patio, small alley, or other safe passageway.

- PUBLIC WAY: An area exposed to open air that leads to a street permanently appropriated for the public and public use. This area can be a street, alley or other land parcel, but by definition has a minimal clear width and height of 10’. What distinguishes a public way from an exit discharge is its size. For example, any alley can be an exit discharge, but if it is 10 feet wide and 10 feet high and it leads to a public street, it is a public

1.3.3.3 Exit Doors

The number of exits required for a structure is based on its intended use and occupancy. Because the normal number of occupants in a residence is less than in a similarly-sized non- residential space, determining a safe level of means of egress is not as complicated.

The Building Code requires all dwellings to have at least one egress door that has direct access from a continuous unobstructed path of travel from all portions of the dwelling to the exterior, without requiring travel through a garage.

The required exit door must be side-hinged and cannot be less than 32” wide by 6’ 6” high. Other doors to the exterior are allowed to have smaller widths.

Each exterior door is required to have a floor or landing on each side of the door except when a stairway with two or fewer risers is located on the exterior side of the door.

The width of the landing should not be less than the width of the door and should have a minimum dimension of 36 inches measured in the direction of travel.

1.3.3.4 Emergency Exits

Basements and each sleeping room need to have at least one operable emergency escape and rescue opening with a minimum clear opening of 5.7 square feet, which opens directly into a public street, public alley, yard, or court.

Emergency escape openings can have a minimum net clear opening height of 24 inches or a minimum width of 20 inches, and must have sill height within 44 inches of the floor.

Emergency escape openings must be operable from the inside of the room without the use of keys or tools or special knowledge. This gives occupants in each sleeping area a method of escape in case of a fire.

1.3.3.5 Windows and Glazing

The light and ventilation requirements of the building code have a major effect on window type, size and placement. Window glass, called glazing, has come a long way since the days when windows had only a single pane of glass. Today’s energy-efficient windows come with glazing “systems” that incorporate multiple panes of glass, gas fillings, and high-tech, heat- sensitive coatings. These new and improved windows may cost more but they pay off in increased comfort and reduced energy costs.

Window Glazing – Ratings:

Window glazing is rated on three criteria: how well it insulates, how much light it lets through, and how effectively it blocks heat from the sun. By taking these values into consideration, you can effectively choose the best windows for the climatic conditions of the property, and even tailor individual windows to best suit specific rooms in the house.

Window Glazing- Hazardous Locations:

The Building Code requires each pane of glass to bear the manufacturer’s label, indicating the type and thickness of glass or glazing material. This safety glazing label has to be acid etched, sandblasted, ceramic-fired, embossed mark, or once applied unable to be removed without being destroyed.

The following are considered hazardous locations for glazing and require special attention or detailing:

- Glazing in swinging doors and storm

- Glazing in sliding and bifold closet

- Glazing in unframed swinging

- Glazing in doors, enclosures, walls and fences enclosing hot tubs, saunas, bathtubs, and showers.

- Glazing in an individual fixed or operable panel next to a door where the nearest vertical edge is within 24 inch arc of the door and the bottom edge is less than 60 inches above any walking

- Glazing in

- Glazing next to stairways, landings and ramps within 36 inches of walking

Window Glazing- Habitable Rooms:

The FBC states that all livable rooms need to have a combined glazing area of not less than 8 percent of the floor area of that room. Natural ventilation should be provided through windows, doors, louvers, or other approved openings to the outside air. These openings need to be readily accessible and controllable by the building occupants. The minimum openable area to the outdoors should be 4 percent of the floor area being ventilated.

Window Glazing- Bathrooms:

Bathrooms have different requirements: There should not be less than 3 square feet of combined glazing area in windows in bathrooms, water closets and similar rooms, half of which is readily controllable.

You can avoid this requirement by providing artificial light and a mechanical ventilation system. The minimum ventilation rates are 50 cubic feet per minute for intermittent ventilation or 20 CFM for continuous ventilation (which is a constant and controlled level of ventilation). Don’t forget ventilated air must always be exhausted directly to the outside.

Window Glazing- Opening Details:

Required glazed openings need to open directly onto a street, public alley, yard, or court located on the same lot as the building.

They can open onto a roofed porch as long as the longer side of the porch is at least 65 percent open and unobstructed and there’s a ceiling height of not less than 7 feet.

Windows are permitted to open into sunroom additions or patio covers that look onto a street, yard or court as long as more than 40 percent of the exterior sunroom walls are open, or are enclosed only by insect screening and if the ceiling height is not less than 7 feet.

The alternative to providing openable windows is to provide mechanical ventilation. Mechanical heating and cooling will be discussed in more depth in Section 5 of this module.

1.3.3.6 Exit Access- Stairways

Stairs can often dictate the layout of an entire structure. Because of their importance in the design process, stairs must be considered early on. The location of railings and balusters, the width and depth of treads, and the height of risers can all affect a stairway’s ease and safety of use, both in terms of everyday use and as part of a means of egress system. Therefore, these dimensions are regulated by most building codes.

The Florida Building Code requires that exterior landings, decks, balconies, stairs and similar facilities, must be positively anchored to the primary structure to resist vertical and lateral forces or shall be designed to be self-supporting. Attachment cannot be completed with nails, such as toenails, that are subject to withdrawal.

Treads, Risers & Landings:

The maximum height of a stair riser is 7 ¾ inches. Within any flight of stairs, the actual measurement cannot be more than 3/8” difference between the greatest riser height and the smallest

The minimum tread depth cannot be less than 10 inches. As with the stair risers, to achieve uniformity of motion, the actual measurement of the tread depth cannot be more than 3/8” difference between the greatest depth and the smallest.

Headroom must also be considered. In all parts of the stairway the minimum headroom is 6 feet 8 inches. This is measured vertically from the sloped plane created by adjoining tread nosings as well as from the finished floor of the landing or platform.

Allowing for this required headroom influences wall placement on an upper floor over the stairwell. Stairways can’t have less than 36 inches clear width between the height of the handrail and the headroom.

Landings should be provided at the top and bottom of each stairway. No vertical rise of more than 12’ is allowed between floor levels or landings. Additionally, the width of the landing can’t be smaller than the stairway it connects to, and every landing needs a minimum dimension of 36 inches measured in the direction of travel. The pitch of treads and landings cannot exceed 2%.

Stairway Lighting:

Lighting is an important element in stairway design. It does not need to be especially bright, but the risers and treads should have sufficient light to ensure that they can be distinguished. All interior and exterior stairways, including landings and treads, must be provided with a means of illumination.

Interior stairways must include an artificial light source located in the immediate vicinity of each landing, capable of illuminating the steps a minimum of 1 foot-candle. Exterior stairways need an artificial light source located at the top landing. Interior stairways with 6 or more risers need to include a light switch on the wall at both the top and bottom of the stairs. Exterior stairways need a light switch that can be controlled from inside the house. However, if the stairway lighting is continuously illuminated or automatically controlled, these switch requirements are not necessary.

Handrail Requirements:

Guards and handrails are needed by a variety of people for very different purposes. For example, they protect people from falling off the edge of the stair tread or landing but also help people keep their balance and provide leverage when ascending/descending stairs.

The maximum projection of the handrails off the wall is 4.5” on either side of the stairway. The space between the wall and the inner edge of the handrail can’t be less than 1- ½”. For a stairway with a handrail on only one side there must be a minimum clear width of 31.5 inches at the height of and below the handrail projection. For a stairway with handrails on both sides, this clear width can’t be less than 27”.

Any stairway with 4 or more risers has to have a handrail on at least one side. The height of which should be between 34 and 38” from the sloped plane created by adjoining adjacent nosings.

Handrails should be continuous for the full length of the flight and the ends should be either returned or terminated in newel posts or safety terminals.

The outside diameter of circular-shaped handrails must be between 1 ¼” and 2 inches. Handrails with a non-circular cross section need a perimeter dimension of 4 to 6 ¼ inches.

Ramps & Guards:

A ramp is an inclined plane that functions with or instead of stairs. Ramps permit wheelchair users, as well as people pushing strollers, carts, or other wheeled objects, to traverse an elevation change.