Chapter: 1 Introduction and Executive Summary

This course provides an overview of the Federal Energy Regulatory Commission’s (FERC’s) role in overseeing the reliable operation of the nation’s bulk power system, i.e., the interconnected electric grid. In order to understand FERC’s reliability program, it is use-ful to first understand the basic structure of how the bulk power system operates. Therefore, the course begins with an explanation of fundamental concepts and functions related to power system operations. The course then discusses FERC’s authority under section 215 of the Federal Power

Act (FPA) with regard to reliability and how FERC has implemented that authority, primarily focusing on the oversight of the development and enforcement of mandatory “Reliability Standards.” Reliability Standards impose requirements on the users, owners and operators of the bulk power system to as-sure that they fulfill their responsibilities in reliable grid operations, consistent with the basic engineering functions and concepts dis- cussed in the course. Finally, the role of the FERC-certified electric reliability organization or “ERO” and its relationship to FERC and electric industry stakeholders is discussed.

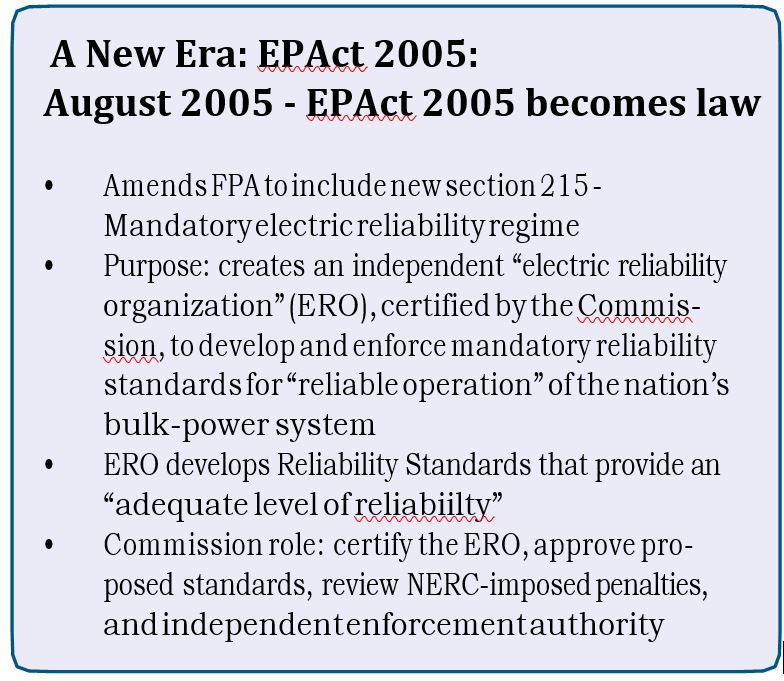

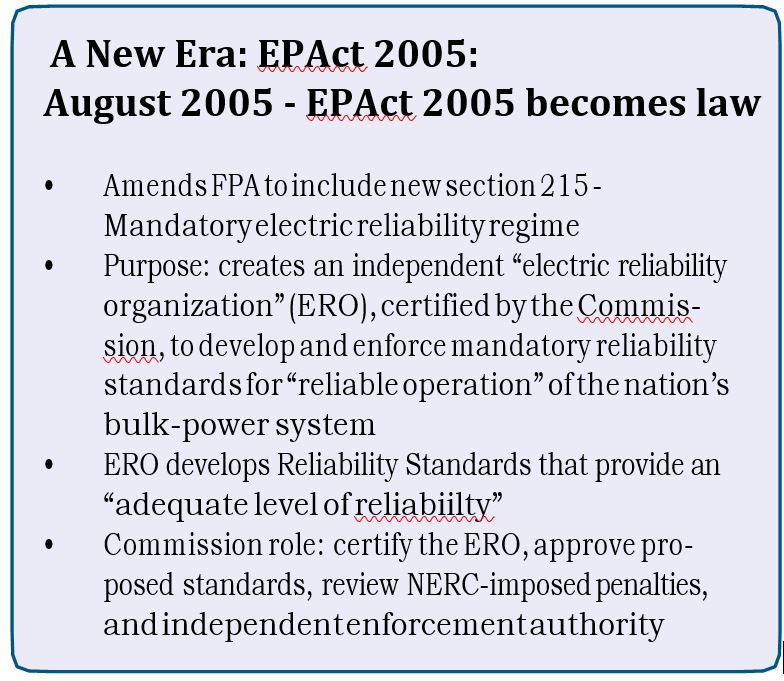

Under Part II of the FPA, FERC historically has regulated certain economic aspects of the public utility industry, such as the rates for sales by one utility to another in interstate commerce. Pursuant to the Energy Policy Act of 2005 (EPAct 2005), Congress expanded FERC’s role and jurisdiction under the FPA by adding a new section 215 pertaining to electric grid reliability. While FERC had previously addressed electric grid reliability in an indirect manner, such as allowing the cost recovery of public utility expenditures that address discrete reliability matters, new section 215 of the FPA tasked FERC with a direct role over an entire new field of activity.

Section 215 of the FPA also differs from other provisions in the FPA because it defines FERC’s jurisdiction in terms of “users, owners and operators” of the bulk power system. This term includes numerous entities that are excluded from most FERC economic regulation, such as federal power agencies, municipal utilities, and rural electric cooperatives. As a result, many entities typically not regulated by FERC had to familiarize themselves with the 2005 reliability legislation and comply with the new requirements. One commonality, however, with other provisions of Part II of the FPA is that section 215 delineates FERC’s jurisdiction in terms of the bulk power system, and expressly excludes facilities used in local distribution from the new reliability scheme.

Congress gave FERC authority to certify a non-governmental entity, referred to as the electric reliability organization, to develop and enforce mandatory “Reliability Standards.” Although Congress did not authorize FERC to write the Reliability Standards, it gave FERC the role of reviewing the Reliability Standards the electric reliability organization develops to ensure they are “just, reasonable, not unduly discriminatory or preferential, and in the public interest.” FERC must approve the electric reliability organization’s Reliability Standards before they can take effect in the United States. Section 215 of the FPA requires independence of the electric reliability organization from the users, owners and operators of the bulk power system. Yet, the statute also requires the electric reliability organization to assure “fair stakeholder representation” in selecting the electric reliability organization board of directors and other aspects of the electric reliability organization, such as committees.

A great amount has been accomplished since 2005. FERC has promulgated regulations defining the structure of the reliability program, certified the North American Electric Reliability Corporation (NERC) as the electric reliability organization, ap- proved eight “regional entities” that serve as regional compliance authorities, approved over 100 mandatory Reliability Standards that address many facets of maintaining and improving bulk power system reliability, issued directives and ordered standards to be developed as well as reviewed thousands of electric reliability organization compliance and enforcement actions.

The task, however, is not complete. Emerging reliability issues require a dynamic program that takes a proactive stance in ensuring ongoing grid reliability. Thus, in addition to maintaining vigilance on fundamentals of grid reliability – such as real-time balancing of load and resources, operating equipment within defined limits, adequate operator training, and tree trimming – emerging areas of concern such as cyber-security and changes in the nation’s resource mix continue to require FERC’s attention.

It is important to understand that in enacting section 215 of the FPA Congress did not “outlaw” blackouts; nor can FERC, the electric reliability organization or anyone else guarantee that blackouts will not occur. However, applying current knowledge and resources, FERC strives to implement its authority over the electric reliability organization and the Reliability Standards in a diligent manner to reduce the possibility of blackouts on the bulk power system.

Chapter: 2 Overview and History of the Electric Power System

Modern society has come to depend on reliable electricity as an essential resource for national security, health and welfare, communications, finance, transportation, food and water supply, heating, cooling, and lighting, computers and electronics, commercial enterprise, and even entertainment and leisure – in short, nearly all aspects of modern life. Providing reliable electricity is an enormously complex technical challenge: it involves real-time assessment, control and coordination of electricity production at thousands of generators, moving electricity across vast interconnected networks of transmission lines, and ultimately delivering the electricity to mil- lions of customers by means of extensive distribution networks.

Modern society has come to depend on reliable electricity as an essential resource for national security, health and welfare, communications, finance, transportation, food and water supply, heating, cooling, and lighting, computers and electronics, commercial enterprise, and even entertainment and leisure – in short, nearly all aspects of modern life. Providing reliable electricity is an enormously complex technical challenge: it involves real-time assessment, control and coordination of electricity production at thousands of generators, moving electricity across vast interconnected networks of transmission lines, and ultimately delivering the electricity to mil- lions of customers by means of extensive distribution networks.

It is these complexities that make the North American electric system such a great engineering achievement. This infrastructure represents more than $1 trillion in asset value, more than 211,000 miles of trans- mission lines operating at 230 kilovolts and greater, over 1.1 million megawatts of generating capability, and nearly 3,500 utility organizations serving over 334 million people whose total electricity demand exceeds 830 gigawatts (830,000 megawatts).

Structure of the North American Electric Power System

Each interconnection in the North American electricity system is essentially one large machine and comprises three main functions: generation, transmission, and distribution, each of which is discussed below. Electric generation (supply) creates electricity using various generating technologies with specific operating characteristics. The trans- mission system connects and transfers large amounts of power from generators to the distribution system, delivering electricity to population centers. The distribution system then routes electricity to individual customers, which are referred to as load. Together, these system parts are connected and operate in an electric balance.

The first electricity systems were independent of each other, serving local communities or regions. As North American electricity demand increased and systems grew, especially after World War II, the systems interconnected. The drivers of interconnection were both technical and economic. Justifications for expansion and interconnection were due to economies of scale, load factor (the ratio of average load

to the peak load for a period of time), and enhancement of reliability. First, the primary electric generators were large thermal plants fueled by coal. These systems have economies of scale, meaning that larger plants have lower per-unit production costs than small plants. Larger plants need a larger customer base, thus encouraging connections among service territories. Increased unit size is advantageous and provides incentives for utilities to connect enough customers so as to take full advantage of economies of scale. Second, by aggregating customers across regions, a higher load factor results, improving system operations. Third, the interconnection of many generators and customers across a wide region improves system reliability through the use of generation pooling which helps to ensure reliable electricity supply despite unexpected generation loss or outage. To this day, some service regions are referred to as “power pools.”2 In North America, there are four separate power grids or “interconnections” (See illustration below). The Eastern interconnection includes the eastern two-thirds of the continental United States and Canada from Saskatchewan east to the Maritime Provinces. In 2006, Québec’s trans- mission system was recognized as a full interconnection because it is not synchronized with neighboring systems. The Western interconnection includes the western third of the continental United States (excluding Alaska), the Canadian provinces of Alberta and British Columbia, and a portion of Baja California Norte, Mexico. The Electric Reliability Council of Texas (ERCOT) interconnection comprises most of the state of Texas. The four interconnections are electrically independent from each other except for a few small direct current (DC) ties. Within each interconnection, electricity is consumed the instant it is produced, flowing over transmission lines from generators to loads.

North American Grid

As shown in the chart below, the United States and Canada share an integrated electrical transmission network. Adding the Baja California region of Mexico, which also has interconnections with the United States, results in what is referred to as the North American interconnected transmission network.

FERC has certain authority over reliability for the portion of the bulk power system located in the United States. Canadian regulatory oversight of electric reliability rests primarily within the jurisdiction of the provinces. In Mexico, regulatory oversight rests with the Mexican Energy Regulatory Commission (Comision Reguladora De Energia or CRE).

These interconnected transmission networks provide economic benefits to each country by allowing electric utility companies to buy and sell power from each other, to save money and to share in the provision of support services that makes the delivery of energy possible. Over 30 international transmission lines are in use between the United States and Canada.

The electric interconnections between the countries also provide alternative power paths during emergencies, such as when a generator unexpectedly trips offline on a hot summer day. Thus, electric interconnections benefit reliability and resiliency of the bulk power system. However, these electrical interconnections can also result in certain vulnerabilities, as was demonstrated during the August 14, 2003 blackout. That blackout began in Ohio and rolled through eastern Canada, impacting its system, before cascading into New York and New England. By following a common set of operating protocols or Reliability Standards in both the United States and Canada, the vulnerabilities of shared interconnections are mitigated.

Generation

Generators are devices that produce electricity. Generators come in many forms and use different methods to convert a fuel or energy source into electricity. The table below shows the amount of generation capacity installed in the United States as of 2014. Natural gas, coal and nuclear energy make up the largest sources.

The various types of generation include:

- Thermal Power Plants: These plants burn fuel in a boiler, producing heat and converting water to steam at a high pressure and The steam is expanded through a turbine, which produces work to drive a generator. Steam plants may use coal, natural gas, oil, biomass, or various types of mineral or vegetative waste (such as by-products from fossil fuel refinement, wood, grasses, etc.) to produce electricity. Gas turbines are essentially natural-gas fired jet engines in which torque is produced to drive a generator. Gas turbines may be started within minutes whereas steam plants may require several hours to begin producing electricity.

- Combined Cycle: In a combined cycle power plant, fuel (typically natural gas) is burned in a gas turbine. A heat recovery system captures the exhaust heat from the turbine and uses that heat to raise steam temperature and pressure, which is expanded through a steam turbine. Both turbines drive electric generators. The heat recovery increases efficiency over a gas turbine or simple steam cycle plant.

- Cogeneration: A cogeneration plant is a simple steam generator that also produces steam for local Common in universities and industrial campuses, these types of power plants produce power and the steam is used for building heating and cooling and industrial applications. Cogeneration plants can have a very high thermal efficiency.

- Nuclear: These plants capture heat released during nuclear fission (or the splitting of uranium atoms) to create steam in a simple steam cycle. Nuclear plants typically operate continuously for 18 to 24 months before undergoing a scheduled maintenance break for refueling.

- Hydroelectric: Hydroelectric plants produce electrical power by passing flowing water through a turbine to drive a The two major types of hydroelectric facilities are impoundment and “run-of-river.” In an impoundment facility, a dam is used to store water, which is then released to drive a generator. In a “run-of-river” facility, a portion of the river’s flow is diverted to a generating station. Hydro- electric facilities are characterized by their high level of availability (given sufficient water levels) and controllability. Utilities balance power production of hydro plants on rivers with other uses, such as flood control, navigation, environ- mental regulations and recreation. Another type of hydro facility, pumped storage, pumps water to higher elevations during low demand hours so that it can be used to produce electricity during peak hours.

- Solar: There are two types of solar generators: photovoltaics and concentrated solar power. Photovoltaics use silicon wafers or non-silicon thin-film panels to convert sunlight directly into electricity and can often be found on homes, commercial buildings, or aggregated into large Concentrated solar power units use mirrors/lenses to focus solar rays toward a receiver where the light energy is concentrated to drive a simple steam cycle generating station.

- Wind: A typical wind turbine has three rotating blades atop a tall tower. The wind turns the blades, directly driving a generator. Units are often grouped together to form wind farms in areas with desirable wind characteristics. The grouping of wind turbines together improves the aggregate availability of the wind farm and its economic viability by harnessing different wind speeds and currents over a larger geographic area.

- Geothermal: These power plants use the heated reservoirs of steam that already exist far below the earth’s crust to provide Most people are familiar with “heat pumps” for residential and commercial heating and cooling that pump liquids through tubing in the ground. Utility-scale geothermal systems are open-loop and closed loop. Open-loop systems tap reservoirs of super-heated steam to drive a steam turbine. Closed-loop systems inject water into wells drilled in geothermal hot spots, which heats the water into steam, which is used to generate electricity.

- Biofuels: These power plants come in several Some use the methane gas by-product of the bacterial decomposition of manure or landfills as the fuel source that is burned to drive a turbine or a small steam-cycle plant. Other biomass plants use non-edible agricultural products and waste such as wood pulp, grasses, corn residue and forest thinnings as a fuel for a simple steam cycle plant.

Given their different fuel types and associated operating characteristics, generators are used to varying extents to serve customer demand or “load,” and generally fall into one of the following categories: base-load, load-following or peaking.

Base-load generation is traditionally comprised of generators that run almost continuously to serve a base level of demand that is typically present on the system due to everyday needs. Most often, nuclear plants, large thermal units, or hydroelectric plants are considered base-load generation. This type of generation is usually large, with respect to size and output, and operates within a steady range of production. For example, nuclear plants produce energy more than ninety percent of the time that they are in service. Due to economies of scale, large thermal fossil fuel plants also are often more economical to run and provide the system with added stability through their design. The large, rotating turbines in these base-load units create spinning mass, which contains kinetic energy known as inertia. Inertia is the momentum and energy built up in the turbines that resists changes due to changing loads by adding to or absorbing energy from the system. These large base-load units also tend to have longer start-up or shut-down times and must operate within a steady range of production. The run-of-river hydro plants, where available, are useful as base-load units because their energy source is constantly flowing. However, regional weather conditions can affect river flows and the amount of hydro-generation available.

Load-following generation is used when the demand for electricity is higher than the base level. Natural gas units have traditionally been used as intermedi- ate or load-following generation. Due to prevailing low prices of natural gas, these plants are increasing- ly used to serve base-load.

Units that can be called upon in a shorter time- frame, such as quick-responding gas combustion turbines, are utilized as peaking units during times of highest demand. While these units may have more operational flexibility, they may not be as economical to run due to their relatively lower efficiency and thus higher fuel and operating costs.

Operating reserves are the capability above firm system demand required to provide for changing demand levels and equipment and system failures.

System operators decide which generators to run based on their economic and operational characteristics or, in many regions, based on prices bid by competing generators. To minimize electricity production costs, system operators dispatch generation in order of cost (or bid) to meet load, unless reliability factors require otherwise. When load is at its peak, more expensive units generally are used to meet the increased demand and the overall cost goes up.

The amount of power needed to serve load constantly changes. System operators must schedule or “dispatch” production by the generators to meet constantly changing demands. Scheduling typically occurs on an hourly basis, and is then fine-tuned throughout the hour, sometimes through the use of automatic generation controls to continuously match generation to actual demand.

Transmission

The transmission function of the North American grid connects and transfers large amounts of power from generators to the distribution system via trans- mission lines, delivering electricity to population areas. Transmission lines are typically constructed using bundles of steel-reinforced copper or aluminum wires called “conductors” and are able to span great lengths with support from steel towers. The towers keep the lines suspended at a safe distance from trees or other objects, as well as maintain enough space between each conductor to keep the lines from connecting or arcing and to avoid mutual interference that could reduce transmission efficiency. Conductors are connected to the tower by insulators which prevent the flow of electricity into the tower. In addition to overhead towers, electricity can also be transmitted through underground or underwater cables, where the construction of a tower is not possible. A cable can include several conductors surrounded by an insulator.

Electricity is transmitted at high voltages. High volt- age transmission can range from 345 kilovolts to 765 kilovolts. In the United States, systems have different characteristics due to location, types of customer, proximity to population, and other considerations such as topography, geography or environmental conditions. Electricity from generators is “stepped up” from a lower voltage (10,000 to 25,000 volts) to higher voltages (i.e., 100,000 to 765,000 volts) for transportation in bulk over transmission lines.

Transmission at high voltage reduces the power losses associated with conductor heating and allows power to be shipped economically over long distances. This is because real losses on a power line are directly proportional to the product of the line resistance and the square of the load current. As the line resistance is relatively fixed per unit of distance (though may change slightly based on factors such as temperature or frequency), a high current will result in large losses. The amount of current required to transfer a given amount of power is inversely proportional to the voltage, thus doubling the voltage halves the current. The desired power level can still be maintained while minimizing line losses by increasing the voltage. As a result, the transmission system relies on higher voltages.

Transmission lines are interconnected at switching stations and substations to form a network of lines and stations that make up the power “grid.” Electricity flows through the interconnected network of transmission lines from the generators to the loads in accordance with the laws of physics in much the same way that water flows through a network of canals: along paths of least resistance. When the pow- er arrives near a load center, it is “stepped down” to lower voltages for distribution to customers.

The first central power plant in the United States, Thomas Edison’s Pearl Street Station in New York City, distributed direct current (DC) power. Today’s electricity transmission and distribution systems are primarily alternating current (AC) facilities. AC power became predominant because of the ease and low cost with which voltages in AC systems can be converted from one level to another. There are a number of modern high-voltage DC (HVDC) transmission links, but these are only a small part of the power grid.

Modern AC power systems are three phase, meaning that the system is comprised of three systems, each operating a third of a 360-degree cycle, 120 degrees, from the other two. Three phase systems have two principal benefits. First, in synchronous generators and motors, three-phase power permits constant torque on the rotor, thus reducing vibration and improving performance. Second, three-phase systems improve the economy of transmission. In principle, every electric circuit must have a return wire. How- ever, in three-phase systems, the sum of the delivered currents is zero, so no return wire is needed. In practice, the small amount of return current may be routed to the ground. This situation assumes that the currents are equal and exactly 120 degrees apart.

Real and Reactive Power

Power transferred along transmission lines consists of both “real” power and “reactive” power. The real power is the energy that is capable of performing work in electrical devices including industrial equipment, refrigerators, or toasters. Reactive power is needed to maintain the voltage as well as electric and magnetic fields in AC equipment, which includes air conditioners, motors, transmission lines, and other devices. Together, real power and reactive power comprise apparent power, which is measured in units of Volt-Amperes or kilo Volt-Amperes – kVA.

Reactive power cannot be transmitted as far as real power and instead must be replenished locally. Moreover, a deficit in reactive power causes voltage to drop. This is seen when the lights dim as an electric motor starts. While reactive power consumed by facilities or devices tends to cause the voltage to drop, it can also be produced or injected into the system to increase voltage in what is often referred to as “voltage support.” This is accomplished in a variety of ways, including by adjusting the reactive power output of generators or by activating capacitor banks or other power electronic equipment. If reactive power is not supplied promptly and in sufficient quantity, voltages decline, and in extreme cases a “voltage collapse” may result.

Transmission lines also face physical limitations based on their characteristics. Following the law of conservation of energy, the energy losses experienced in transmission (due to the resistance multi- plied by the current squared) are transformed into heat that cause lines to stretch and sag. This expansion can cause the line to come into contact with trees or other objects and cause a fault, or may lead to permanent physical changes and damage to the line. Thus transmission lines have thermal ratings that determine the maximum amount of electricity a line can safely conduct, thus limiting the amount of power that can be transferred. The thermal ratings can vary seasonally with the ambient temperature and with system conditions, such as normal (or continuous ratings) and emergency operation ratings. Emergency ratings may have a time limit associated with them such as a two-hour or four-hour rating. In addition, lines have voltage limits and other controls to make sure that generators and other elements at each end of the line are able to synchronize with the system when connecting. Because electricity flows freely and almost simultaneously across the power system, transmission lines may also have preset power transfer limits to avoid overloading other lines during certain system conditions.

Transformers and Substations

Transformers are devices that convert AC power from one voltage to another. Transformers are essentially a conductive core that facilitates the transfer of electric energy between two or more sets of line windings through magnetic fields. Transformers are used in electric power systems to convert voltages to a higher (“step-up”) or lower (“step- down”) voltage. For example, generators produce power at lower voltage levels and the power must be stepped up by transformers near the generation site before joining the transmission network.

AC current flowing through the source (primary) winding of a transformer creates an oscillating magnetic field within the conductive core and produces an induced voltage potential across the load (secondary) winding. This causes electrons to flow in the secondary winding and produces another AC current at the output. The strength of the voltage induced is dependent on the ratio of turns in the winding; if the number of turns is greater in the primary winding, then the resulting voltage will be smaller, or stepped down. If the number of turns is greater in the secondary winding, the resulting voltage will be greater, or stepped up. Various configurations can support multiple sets of windings, such as a third set of windings to provide local power. It is also possible to connect or “tap” the windings so that the number of turns used can be changed, thus controlling the resulting induced voltage as needed.

Transformers and associated equipment comprise the interface between two different transmission-level voltages, between generators and transmission, and between the transmission system and the distribution system. High voltage transformers, also referred to as “intertie banks,” deliver large amounts of power to highly populated areas or “load pockets” that may not have enough local generation. These large intertie banks are difficult and costly to replace because of their size, unique designs, and long manufacturing times. For these reasons, many utilities keep spare equipment on hand.

Transformers and other equipment needed to switch between voltage levels and multiple line terminals are contained within substations. Substations also contain a number of system control devices and protective elements that insulate electricity to keep equipment and people working within substations safe. Switches or circuit breakers are used to disconnect elements or portions of the system to isolate them, often for maintenance or to mitigate an unexpected disturbance on the line. Some switches take advantage of open air as an insulating medium when physically removing connections. This event often can result in arc flashes at high voltage levels as the conductors separate, though the arcs dissipate quickly once there is enough distance between contacts.

Switches may also be contained within a vacuum or in the presence of an inert gas, which both are better insulators than air. Additionally, circuit breakers are used to separate sections of the system when faults are detected. Bushings are insulated connectors for equipment, such as circuit breakers or transformers to conductors. Substations also house equipment used to maintain the voltage across the system such as the capacitor banks, reactors, and static-VAR compensators.

Distributions

The distribution system is generally comprised of sub-100kV lines that ultimately deliver power to customers, such as a home or business. Once power is generated and transferred over transmission lines to the vicinity of the load, the voltage must once again be lowered to move along the distribution lines.

This happens at a substation that uses transformers to step-down the voltage. From the substation, energy can be transferred either directly to the load or must be stepped down again. Some large industrial and commercial customers take service at intermediate voltage levels (12,000 to 115,000 volts), but most residential customers take their electrical service at 120 and 240 volts. Electric utilities ensure that this voltage stays within a specified range.

Other Equipment

Because the electric power system needs to perform continuously, efforts are taken to ensure that operations will continue during and after an undesired event. These events may often be the result of a lightning strike, or a tree or animal that has made contact with a line, causing a low-resistance connection that carries excessive current flows to unintended paths (often called a “short circuit” or “fault”).

To mitigate these events, protection systems that detect these high currents and other system problems and take automatic actions have been designed and deployed. The main purpose of these devices is to monitor and/or react to events and to minimize damage and maintain reliability. Collectively, these devices constitute the “protection system.”

Protection system devices are installed on the grid to protect and isolate the entire power system from trouble that emerges in isolated locations, while leaving as much of the grid as operational as possible. Protection systems can be viewed as having five principal components:

(1) current and voltage “transformers” measure currents and voltages and provide signals to relays;

(2) protective relays that sense faults and initiate a “trip” or disconnect;

(3) circuit breakers that open and/or close the line based on relay and other commands;

(4) batteries to provide power in case of power disconnection in the system; and

(5) communication channels to allow analysis of current and voltage at remote terminals of a line and allow remote tripping of equipment.

Relays and circuit breakers that isolate affected sections of a line are often the first line of defense. Relays monitor many aspects of the system, including: temperature, current, and voltage. Depending on the situation, a relay will “trip” a circuit breaker that takes a portion of the system out of service by disconnecting the line to protect the rest of the network. Often, relays will automatically “re-close,” meaning that they will reconnect after a preset delay under the assumption that the source of the fault is temporary. However, if the fault is still present, the relay will permanently remove the affected portion of the line from service until the fault can be resolved by maintenance crews. The application of these devices is designed to remove from service the smallest part of the system possible until restoration can be achieved. For redundancy, often there are secondary and tertiary back-up relays that are timed to watch for the clearing of a fault. If the system fault is still present after a set period of time, they will activate, though a larger portion of the line may then be out of service. Other relays will act to regulate the system characteristics within a certain range, or will trip if a prolonged over-current or over-voltage is detected.

Chapter: 3 Function and Concepts of Electric Power System Operations

Function and Concepts of Electric Power System Operations

The previous section discusses the structure of the North American electricity system and describes the three main functions (generation, transmission, and distribution) and how each interconnection within the system operates as essentially one big machine. Maintaining the reliability of the grid is a complex enterprise that requires trained and skilled opera- tors, sophisticated computers and communications, careful planning and design, and rigorous maintenance practices, including tree-trimming or “vegetation management,” and equipment maintenance. This section describes some of the aspects of reliably operating the grid. Reliable operation of the power grid is complex and demanding for two fundamental reasons:

- At present, it is difficult to store large quantities of electricity economically. Therefore, electricity must be produced the instant it is needed and

- The flow of AC electricity cannot be controlled like a liquid or gas by opening or closing a valve in a pipe, or switched like calls over a long-distance telephone Electricity flows freely along all available paths from the generators to the loads along the “path of least resistance.”

The unique characteristics of electricity mean that problems, when they arise, can spread and escalate very quickly if proper safeguards are not in place. Accordingly, through years of experience, the electric industry has developed a network of defensive strategies for maintaining reliability based on the assumption that equipment can and will fail unexpectedly on occasion. This principle is expressed by the requirement that the system must be operated at all times to ensure that it will remain in a secure condition (generally within emergency ratings for current and voltage and within established stability limits) following the unexpected loss of the most important generator or transmission facility (a “single largest contingency”). This is called the “N-1 criterion.” In other words, because a generator or line trip can occur at any time, the power system must be operated in a preventive mode. Use of the N-1 criterion means that the loss of the most important genera- tor or transmission facility does not jeopardize the remaining facilities in the system by causing them to exceed their emergency ratings or stability limits, which could lead to a cascading outage.

When a contingency does occur, system operators are required to identify and plan for the next contingencies based on the changed conditions. They must also promptly make any adjustments needed to ensure that if one of these contingencies were to occur, the system would still remain operational and safe. Generally, the system must be restored to normal limits as soon as practical but within no more than 30 minutes, and to a condition where it can once again withstand the next-worst single contingency without violating thermal, voltage, or stability limits. Most areas of the grid are operated to withstand the concurrent loss of two or more facilities (i.e., “N-2” or “N-3”). This may be done, for example, as an added safety measure to protect a densely populated metropolitan area or when lines share a common structure and could be affected by the same event (e.g., a single lightning strike).

Ensuring the reliability of a transmission grid involves several other key concepts, which are discussed below: Frequency Control – Balance of Generation and Load, Voltage Control – Maintaining Required Voltage Level, Power Flow and Stability Control, Short-Term and Long-Term Planning, Vegetation Management, Coordination and Communication, and Critical Infrastructure Protection.

Frequency Control – Balance of Generation and Load

The “frequency” of the AC power system in the United States is set at 60 cycles per second or 60 Hertz (Hz). Failure to match generation to demand causes the frequency of the power system to fluctuate higher or lower than the normal 60 Hz. When generation exceeds the load or demand to consume it, the system frequency increases; when there is less generation being produced than is needed to serve load, the frequency decreases. Random, small variations in frequency are normal, as loads constantly in- crease or decrease, and generators modify their out- put to follow the demand changes. However, large deviations in frequency can cause the rotational speed of generators to fluctuate, leading to vibrations that can cause damage to generator turbine blades and other equipment. Extremely low frequencies can trigger automatic under-frequency “load shed- ding” to enable frequency to increase, which takes sets of customers off-line to prevent a total collapse of the electric system. Such an imbalance of generation and demand can also occur when the system responds to major disturbances by disconnecting into separate “islands”; any such island may have an excess or a shortage of generation when compared to the demand within the island. The figure below presents the concept of frequency control in terms of maintaining the level of water in a tank.

Many processes in place help to maintain the system frequency at (or close to) 60 Hz. One inherent quality of the system is inertial energy, or momentum that resists sudden changes in speed. The large amounts of energy stored in rotating masses (such as the spinning turbines of generation plants) are resistant to changes in rotational speed. The inertia resists a decline in speed caused by a loss of generation, allowing control systems a brief opportunity to automatically produce more power from the remaining generators. This response often occurs in milliseconds. Conversely, when load is added to the system causing the frequency to decrease, rotational energy from the generator will be converted into electrical energy to serve the load and maintain a balance. To further control these rotational speeds, generators also have a device called a “governor.” The governor monitors the shaft speed of a genera- tor and either increases or decreases the amount of turbine-spinning force, by controlling the steam in- put to the turbine, to proportionally adjust the shaft speed back to the desired level. Governors on trucks or boats work exactly in the same manner, allowing only a steady and measured decrease or increase in drive train rotational velocity to prevent equipment damage and maintain safe operating practices. This frequency response occurs in a fraction of a second, before system operators are able to take action. For example, the sudden loss of a large generator in Kentucky can cause a frequency dip in the entire Eastern interconnection, from Miami up to Toronto, during which time all of the generators with automatic generation control mode in the interconnection will respond by incrementally increasing the amount of energy they produce to make up for the sudden loss of this one generator.

Voltage Control – Maintaining Required Voltage Level

As the load changes, so do the requirements for reactive power throughout the system. Reactive power sources, such as capacitor banks and generators, adjust to maintain voltages within a specified range for all system electrical equipment (e.g., stations, transmission lines, and customer equipment see previous “box” on Reactive Power Analogy). Most genera- tors have automatic voltage regulators that cause the reactive power output to increase or decrease based on system conditions, thus controlling voltage in an area. A system voltage schedule is set by the trans- mission operator and is designed to maintain the system within reliable operating limits. This schedule is done in advance so the transmission operator can convey voltage needs to area generators, and the generators can then be ready to respond based on their specific capabilities and requirements. When necessary, devices called reactors are used to contain excess reactive power by increasing the line reactance (the reactive component of impedance that absorbs or emits reactive power). Static VAR compensators and static synchronous compensators (also known as STATCOMs) are devices that inject and absorb reactive power and are used to maintain voltage by adjusting the impedance of the system.

Large deviations in voltage levels can have severe impacts. Low voltage can cause electric system in- stability or collapse and, at distribution voltages, can cause damage to motors and the failure of electronic equipment. Low voltage levels occur when there is a lack of reactive power, which can result from a load-driven surge of reactive power demand or when there are high reactive power losses due to heavy power transfers. At the other extreme, high voltages can exceed the insulation capabilities of equipment and cause dangerous electric arcs known as “flash- overs.” These conditions can occur when there is light loading on the system (e.g., less customer demand), causing an excess of reactive power that elevates the voltage beyond safe operating limits. Outages of reactive power equipment, transmission lines, or generators can also contribute to both under-and over-voltages.

Power Flow and Stability Control

Because the electric system is interconnected and dynamic, the system must be operated within electrical stability limits. Stability problems can develop very quickly – in time-frames ranging from milliseconds to minutes. Electricity system operators often describe events in terms of the number of “cycles” of alternating current that pass. One cycle is 1/60th of a second. The main concern is to ensure that gen- eration dispatch and the resulting power flows and voltages are such that the system is stable at all times. Stability limits, like thermal limits, are expressed as a maximum amount of electricity that can be safely transferred over transmission lines.

There are two types of stability limits. First, voltage stability limits are set to ensure that the unplanned loss of a line or generator (which may have been providing locally critical reactive power support, as described previously) will not cause voltages to fall to dangerously low levels. If voltage falls too low, it begins to collapse uncontrollably, at which point automatic relays either shed load or trip generators to avoid damage. Second, power (angle) stability limits are set to ensure that a fault or an unplanned loss of a line, transformer, or generator will not cause the remaining generators and loads being served to lose synchronism with one another (recall that all generators and loads within an interconnection must operate at or very near a common 60 Hz). Loss of synchronism with the common frequency means generators are operating out-of-step with one another. Even modest losses of synchronism can result in damage to generation equipment. Under extreme losses of synchronism, the grid may break apart into separate electrical islands; each island would begin to maintain its own frequency, determined by the load/ generation balance within the island.

Short-Term and Long-Term Planning

Reliable power system operation requires far more than monitoring and controlling the system in real-time. Thorough planning, design, maintenance, and analysis are required to ensure that the system can be operated reliably and within safe limits. Operations planning looks at day-ahead, week-ahead, seasonal and up to one year planning horizons. Short-term planning addresses one to five year planning horizons. Long-term planning focus- es on providing adequate generation resources and transmission capacity to ensure that in the future the system will be able to withstand severe contingencies without experiencing widespread, uncontrolled cascading outages.

A utility that serves retail customers must estimate future loads and, in some cases, arrange for adequate sources of supplies and plan adequate transmission or distribution infrastructure. Utilities must identify a range of possible contingencies and set correspond- ing expectations for system performance under several categories of possible events, ranging from every day “probable” events to “extreme” events that may involve substantial loss of customer load or generation in a widespread area. Utilities must also address requirements for voltage support and reactive power, disturbance monitoring, facility ratings, system modeling and data requirements, system protection and control, and system restoration.

System operators must take the steps described above to plan and operate a reliable power system. However, emergencies can still occur because of external factors such as severe weather, operator error, or equipment failures that exceed planning, design, or operating criteria. For these less frequent events, an operating entity maintains emergency procedures that address a credible range of emergency scenarios. System operators must be trained to recognize and take effective action in response to these emergencies. To deal with a system emergency that results in a blackout, such as the one that occurred on August 14, 2003, system operators must have procedures and capabilities to use “black start” generators, which are capable of restarting and synchronizing with no external power source, and to coordinate operations to quickly restore the system to a normal and reliable condition.

Vegetation Management

Vegetation management is critical to any utility company that maintains overhead energized lines because electric power outages can occur when trees, or portions of trees, grow or fall onto overhead electric power lines. While not all vegetation-related outages can be prevented (due to storms, high winds, etc.), some outages can be mitigated or prevented by managing the vegetation before it becomes a problem. Tree contact with a power line causes a fault, which signals the line’s relays to remove the line by interrupting the current flow. Direct physical contact is not necessary for a fault to occur. An electric arc can occur between a part of a tree and a nearby high-voltage conductor if a sufficient distance separating them is not maintained. Arcing distances vary based on such factors such as voltage, ambient temperature, and humidity conditions. Arcs can cause fires as well as faults and line outages. Most utilities have right-of-way and easement agreements allowing the utility to trim vegetation as needed along their lines to provide safe and reliable electric power. Electric utilities enter into easements or agreements with landowners to establish contractual rights regarding what can be pruned or removed in the transmission right-of-way. Transmission easements generally give the utility a great deal of control over the landscape, with rights to do whatever work is required to maintain the lines with adequate clearance through the control of vegetation.

FERC has approved a Reliability Standard on vegetation management, to reduce the risk of outages caused by inadequate tree trimming. This Reliability Standard, however, applies only to high voltage lines, typically 200 kilovolts and higher. Tree trimming for lower voltage lines generally falls under the jurisdiction of state or local authorities.

Coordination and Communication

Operating the electric system continuously at an optimal state requires that numerous entities communicate effectively in real-time to maintain the system balance between generation and load, stay within operating limits, and address issues that may arise.

This communication occurs both through interpersonal channels (telephone, radio, email) and auto- mated data exchange systems (e.g., links between neighboring transmission operators). The principal entities involved in coordination and communication include:

- Reliability coordinator: The entity that is the highest level of authority responsible for the reliable operation of the electric power system; it has a wide-area view, and has the operating tools, processes and procedures, including the authority to prevent or mitigate emergency op- erating situations in both next-day analysis and real-time operations. The Western interconnection and ERCOT interconnection each have one reliability coordinator, while the Eastern interconnection has 11 reliability

- Balancing authority: The entity that is initially responsible for maintaining the balance between generation and load within a “balancing authority area,” which is its defined electric Approximately 105 balancing authorities across the United States collectively make-up the areas where generation and load need to be kept in balance.

- Transmission operator: The entity that is responsible for the reliability of its “local” trans- mission system, and that operates or directs the operations of the transmission While some entities both own and operate transmission assets, others do not. Transmission opera- tors that do not own the transmission facilities have agreements with the owner to coordinate and operate those facilities. Approximately 315 transmission operators are registered with NERC to operate these “local” transmission systems across the United States.

- Generator operator: The entity that operates generating facilities and performs the functions of supplying energy and interconnected operations While some entities both own and operate generation assets, this is not always the case. Generator operators that do not own the generating facilities have agreements with the owner to coordinate and operate those facilities. Approximately 936 generation entities are registered with NERC across the contiguous United States. Many of these entities own more than one generator, and not all generators fall under NERC authority.

- Distribution provider: Provides and operates the “wires” between the transmission system and the end-use For those end-use customers who are served at transmission voltages, the transmission owner also serves as the distribution provider. Thus, the distribution provider is not defined by a specific voltage, but rather as performing the distribution function at any voltage. Approximately 393 entities are registered with NERC for this function across the United States.

The reliability coordinator typically has the highest level of authority, followed by the transmission operator and the balancing authority. These entities must maintain continuous communications with each of the appropriate entities, which also include neighboring entities that are affected by conditions within an operator’s area. Additionally, these entities must have plans to restore communications and establish an alternative communication capability.

Critical Infrastructure Protection

Physical Security

Physical security for the electric power system revolves around the protection of essential assets from physical harm. Different types of facilities present different physical security challenges. Centralized facilities that are normally manned, such as control centers, communication facilities, and corporate offices, present a different physical security challenge than do the decentralized and typically unmanned facilities, such as substations and transmission lines. While the more centralized nature of attend- ed facilities allows more focused and economical security measures, this advantage is balanced against the risks associated with the greater impact to the electric power system by a failure of that facility. As such, these centralized facilities need to use the most stringent security controls. Decentralized facilities, on the other hand, will often rely on automated security controls monitored from a different facility. This presents a different challenge to keep up to date with both automated security control technologies and communication technologies to ensure effective security for such facilities.

Physical security typically comprises at least six distinct concepts:

- Deter – visible physical security measures in- stalled to induce individuals to seek other, less secure targets.

- Detect – physical security measures installed to detect unauthorized intrusion and provide local and/or remote intruder alarms.

- Delay – physical security measures installed to delay an intruder’s access to a physical asset and provide time for incident assessment and response.

- Assess – the process of evaluating the legitimacy of an alarm and the procedural steps required to respond.

- Communicate – communication systems used to send and receive alarm/video signals and voice and data Also, includes the documented process to communicate detected intrusions.

- Respond – the immediate measures taken to assess, interrupt, and/or apprehend an intruder.

Cyber Security

For many years the control systems for utilities and industrial companies have operated in a stand-alone environment without computer or communication links to external information technology infrastructure. More recently, such stand-alone systems have been increasingly connected to both the corporate information technology environment and the external world via the Internet, and the electric power system is no exception to this trend. Computer and communication network interconnection brings with it the potential for cyber-attacks on these systems by adversaries. The problem is particularly important because such an attack can potentially affect several entities across the country simultaneously.

Controlling electronic access is one of the keys to preventing a successful cyber-attack. An adversary that can gain electronic access to a computer system may be able to gain control over that system and use it for his purposes. In today’s environment, many infrastructure control systems have an electronic pathway that leads to the outside world, which can create a potential for access that is vulnerable to exploitation by an adversary.

The potential solution to such cyber threats is a strong cyber security posture by entities that may be vulnerable to such attacks. A major challenge to preserve system protection is that computer and communication system architectures change, technology changes, and threats change, all of which means that defenses must change. Traditionally, threats can change faster than defenses. To meet or minimize these risks, one widely recognized cyber security strategy is “defense in depth.” This strategy involves layering of defense mechanisms in a way that discourages an attack and increases the potential that an entity will be alerted to an attack on it. While other strategies exist, defense in depth is a widely accepted, effective strategy to address cyber threats that is both comprehensive and flexible.

The development of a home security system provides a useful analogy for understanding the defense in depth strategy. For example, a home security system might include the following defenses:

(1) a motion sensor light that goes on whenever some- one gets close to the house,

(2) a video camera that records the approaches to the house,

(3) a door with a deadbolt lock and a chain,

(4) an alarm system that activates if a door or window is opened (along with decals notifying a potential intruder that the system exists), and

(5) a dog inside the house. Several of these items are designed to keep an intruder out, some are designed to activate if an intruder gains access, and some are designed to record the event if it occurs.

Each of these measures provides some degree of protection and, in combination, substantially increases the chances of successfully deterring a burglary.

Cyber defenses work in a similar manner. Some defenses, like firewalls, are designed to keep intruders out. Others, like intrusion detection systems, are designed to activate if someone gains access.

Still others, like audit logs, are designed to inform a computer operator whether another person has gained access. Information sharing, where entities voluntarily share information about attempted or successful access attempts with each other, is also a valuable security control. The combination of all of these technologies, and how they are combined and implemented, determines whether computer securi- ty personnel have effectively protected cyber assets.

Whereas grid operations usually involve readily measured quantities and activities, cyber security involves a careful balance of the technologies avail- able with the existing control equipment and the functions they perform. Compared to general grid operations, cyber security is in many ways as much, or even more, a matter of subjectively balancing physical and technical options rather than a purely objective task of achieving a single, steady, physical state. The task of balancing technical options for cybersecurity comes into play as one selects and combines various available technologies into a comprehensive architecture to protect the specific computer environment.

Major Blackouts and Responses

System failures, particularly when compounded with multiple problems, can result in cascading blackouts across multiple operating systems. System planners study such cascading disturbances and draw lessons from them to prepare their systems and avoid these problems in the future. Below is a description of some of the most severe cascading blackouts experienced in North America.

November 9, 1965: Northeast Blackout

On November 9, 1965, a blackout occurred in the northeastern United States and southeastern Ontario, Canada that affected 30 million people and interrupted more than 20,000 MW of electrical load for up to thirteen hours. This event is often referred to as “the Great Northeast Blackout,” mainly because this was one of the most significant blackout events of the time and affected major population centers such as New York City, Boston, and Toronto, as well as smaller or rural areas. Virtually all of New York, Connecticut, Massachusetts, Rhode Island, small segments of northern Pennsylvania and northeastern New Jersey, and substantial areas of Ontario, Canada, were affected.

The blackout was caused by the tripping of a 230 kV transmission line near Ontario, Canada, which caused several other heavily loaded lines also to fail. An initial protective relay tripped (due to incorrect settings) when a transmission line was overloaded. This also caused several other relays to operate on other transmission lines, which resulted in a power surge that overwhelmed the transmission system in western New York. Several generators also tripped off-line according to design because they were unable to transmit their power due to the overload- ed transmission lines. The resulting power swings caused a cascading outage that blacked out much of the Northeast.

Subsequent blackouts

Several other notable blackouts occurred through the years, but the November 1965 outage is significant due to the geographic size of the outages and underlying mechanical or human failures, rather than weather related causes. The July 13, 1977 New York City blackout occurred when two 345-kV lines on a common tower in Northern Westchester County, New York were struck by lightning and tripped out. With the loss of power imports ordinarily carried by these lines, generation in New York City was not sufficient to serve the load in the city, leading to load loss. The event affected nine million people, with 6,000 MW of load lost. Outages lasted for up to 26 hours.

A West Coast blackout occurred on December 22, 1982. This disturbance began when high winds caused the failure of a 500-kV transmission tower. This ultimately resulted in the loss of 12,350 MW of load and affected over 5 million people in the West.

On July 2-3, 1996, a 345-kV transmission line in Idaho sagged into a tree and tripped on July 2. A protective relay on a parallel transmission line detected the same fault and incorrectly tripped a second line. Similar conditions and initiating factors were present on July 3; however, as voltage began to collapse in the Boise, Idaho area, the operator dis- connected customers to maintain system integrity.

This event resulted in the loss of 11,850 MW of load and affected 2 million people in 14 states; Alberta and British Columbia in Canada; and Baja California Norte in Mexico. Outages lasted from a few minutes to several hours.

Another western interconnection blackout followed on August 10, 1996 when the transmission system from Canada south into California was heavily loaded with north-to-south power transfers. These flows were due to high Southwest demand caused by hot weather, leading to transmission lines sagging into untrimmed trees, causing the system to trip out. This resulted in the loss of over 28,000 MW of load and affected 7.5 million people in many of the same 14 states as the previous month’s event; Alberta and British Columbia in Canada; and Baja California Norte in Mexico. Outages lasted from a few minutes to as long as nine hours.

August 14, 2003: Midwest and Northeast US-Canadian Blackout

On August 14, 2003, the North American power grid experienced its largest blackout ever, impacting large portions of the Midwest and Northeast United States and Ontario, Canada. The outage affected an estimated 50 million people and 61,800 MW of electric load was lost in the states of Ohio, Michigan, Pennsylvania, New York, Vermont, Massachusetts, Connecticut, New Jersey and the Canadian province of Ontario. Although utilities successfully restored power to most customers within hours, some areas in the United States did not have power restored for several days. Parts of Ontario suffered rolling blackouts for up to two weeks before full power was restored. Estimates of total costs in the United States ranged between $4 billion and $10 billion; in Canada, gross domestic product was down 0.7 percent in August, there was a net loss of 18.9 million work hours, and manufacturing shipments in Ontario were down C$ 2.3 billion.

A combination of human error and equipment failures caused the August 14, 2003 blackout. A generating plant near Cleveland, Ohio tripped offline amid high heat and high electrical demand. The hot day also caused power lines to sag as power losses due to higher currents heated the lines. A transmission line in northern Ohio sagged into overgrown trees and tripped. Three other transmission lines sagged into trees and switched off, forcing other power lines to shoulder the extra burden. Normally, the problem would have activated an alarm in the control room but the alarm system failed. As designed, the power was diverted to other transmission lines, but they were not able to handle the increase. This, in turn, activated these lines’ relays which tripped lines and again diverted greater amounts of power to other transmission lines. For the next hour and a half, system operators tried to understand what was happening as load was shifting and transmission lines were overloading. Once the multiple line trips occurred, multiple generators also tripped out to prevent dam- age. The failures cascaded throughout southeastern Canada and eight northeastern states.

As with previous cross-border blackouts, the United States and Canadian governments conducted a joint-review into the events that occurred. A U.S. – Canadian Power System Outage Task Force, including personnel from FERC, carefully investigated the causes of the blackout and issued a detailed report that made recommendations on ways to reduce the possibility of recurrence.

The causes of the outages and the cascading significant load drops were many, but were summarized as the “3 Ts” – trees, tools and training. Overgrown trees had contacted multiple high-voltage transmission lines, tripping them out of service and thus increasing the load on the remaining lines that caused further sagging on additional lines, resulting in even more lines tripping. The system operators in the Midwest region at the time did not have the tools to make them aware of this chain of events, allowing the reliability problem to cascade further. The cascade continued onward as system operators did not have timely awareness of the events taking place. When they did begin to recognize the trouble, the system operators did not have adequate training on how to respond to the emergency conditions.

The causes of the outages and the cascading significant load drops were many, but were summarized as the “3 Ts” – trees, tools and training. Overgrown trees had contacted multiple high-voltage transmission lines, tripping them out of service and thus increasing the load on the remaining lines that caused further sagging on additional lines, resulting in even more lines tripping. The system operators in the Midwest region at the time did not have the tools to make them aware of this chain of events, allowing the reliability problem to cascade further. The cascade continued onward as system operators did not have timely awareness of the events taking place. When they did begin to recognize the trouble, the system operators did not have adequate training on how to respond to the emergency conditions.

The report included 46 recommendations for the industry and entities to undertake, including that “the U.S. Congress should enact the reliability provisions…to make compliance with Reliability Standards mandatory and enforceable. If that could be done, many of the other recommended actions identified in the report could be accomplished readily in the course of implementing the legislation.”

Chapter: 4 NERC – From a Voluntary Council to Electric Reliability Organization with Mandatory Reliability Standards

Following the 1965 Northeast Blackout, the National Electric Reliability Council (the predecessor organization to the North American Electric Reliability Corporation and also referred to as NERC) was established to provide a means for coordinating among interconnected utilities to ensure that the interconnected transmission network in the United States was reliable, adequate and secure. Additional- ly, regional reliability organizations were formalized under NERC, as well as regional planning coordination guides, which NERC maintained. The utilities maintained and practiced voluntary operating criteria and guides. NERC successfully operated for numerous years as a voluntary organization, rely- ing on reciprocity, peer alignment, and the mutual self-interest of all involved to ensure the voluntary compliance with reliability requirements.

Following the 1965 Northeast Blackout, the National Electric Reliability Council (the predecessor organization to the North American Electric Reliability Corporation and also referred to as NERC) was established to provide a means for coordinating among interconnected utilities to ensure that the interconnected transmission network in the United States was reliable, adequate and secure. Additional- ly, regional reliability organizations were formalized under NERC, as well as regional planning coordination guides, which NERC maintained. The utilities maintained and practiced voluntary operating criteria and guides. NERC successfully operated for numerous years as a voluntary organization, rely- ing on reciprocity, peer alignment, and the mutual self-interest of all involved to ensure the voluntary compliance with reliability requirements.

By 1981, NERC had expanded to include the inter- connected electric systems in Canada and its name was changed to the North American Electric Reliability Council to more accurately reflect the broader scope of NERC’s membership. As the electric industry evolved, the regional councils broadened their membership to include all segments of the electric industry: investor-owned utilities; federal power agencies; rural electric cooperatives; state, municipal and provincial utilities; independent power producers; power marketers; and end-use customers. Collectively, the members in the NERC regions account for virtually all the electricity supplied in the contiguous United States, Canada, and a portion of Baja California Norte, Mexico.

After the 2003 blackout, NERC’s role and responsibilities changed. Congress added section 215 to the FPA in 2005, which authorized the development of mandatory Reliability Standards by an independent electric reliability organization.

FERC established rules and regulations governing the formation and certification of an electric reliability organization in accordance with the reliability provisions of the newly enacted legislation. In April 2006, NERC filed an application with FERC for certification as the electric reliability organization. NERC also submitted 107 Reliability Standards to FERC for approval. The 107 proposed Reliability Standards were largely the existing voluntary proto- cols and guidelines repackaged to be the mandatory and enforceable Reliability Standards under the new statute. Concurrently with its FERC application, NERC made filings seeking comparable recognition from government authorities in Canada, including the provinces of British Columbia, Alberta, Saskatchewan, Manitoba, Ontario, Quebec, New Brunswick, and Nova Scotia, and the National En- ergy Board. Today, NERC is recognized as an electric reliability standards-setting organization in its role as the North American ERO.

FERC established rules and regulations governing the formation and certification of an electric reliability organization in accordance with the reliability provisions of the newly enacted legislation. In April 2006, NERC filed an application with FERC for certification as the electric reliability organization. NERC also submitted 107 Reliability Standards to FERC for approval. The 107 proposed Reliability Standards were largely the existing voluntary proto- cols and guidelines repackaged to be the mandatory and enforceable Reliability Standards under the new statute. Concurrently with its FERC application, NERC made filings seeking comparable recognition from government authorities in Canada, including the provinces of British Columbia, Alberta, Saskatchewan, Manitoba, Ontario, Quebec, New Brunswick, and Nova Scotia, and the National En- ergy Board. Today, NERC is recognized as an electric reliability standards-setting organization in its role as the North American ERO.

FERC certified NERC as the electric reliability organization in July 2006 and, at the start of 2007, NERC reorganized as a corporation: the North American Electric Reliability Corporation. In March 2007, FERC approved 83 of NERC’s proposed 107 Reli- ability Standards, which were the first set of legally enforceable mandatory standards for the U.S. bulk power system, to become effective June 2007. For the remaining 24 proposed standards, FERC deter- mined that NERC must submit additional information. However, FERC held that NERC and the utilities should voluntarily comply with NERC’s non-approved standards as good utility practice while FERC continued to evaluate them.

FERC also approved delegation agreements by which NERC delegates its authority to monitor and enforce compliance with NERC Reliability Standards to the eight regional entities, with NERC continuing in an oversight role. Under NERC’s oversight, the regional entities perform certain aspects of the electric reliability organization functions through these delegation agreements. The delegation agreements with each regional entity address, among other things:

- Development of regional Reliability Standards

- Monitoring compliance with and enforcing mandatory Reliability Standards (both North American wide and regional), certification of registered entities, and registration of owners, operators and users of the bulk power system

- Reliability assessment and performance analysis

- Training and education

- Event analysis and reliability improvement

- Situation awareness and infrastructure security

Today, NERC is a not-for-profit international entity whose mission is to assure the reliability of the bulk power system in North America. NERC develops and enforces Reliability Standards; annually assesses seasonal and long-term reliability; monitors the bulk power system through system awareness; and educates, trains, and certifies industry personnel. NERC’s activities cover the users, owners, and operators of the bulk power system, which serves more than 334 million people. NERC-developed Reliability Standards apply in whole or part to more than 1,400 bulk power system users, owners and operators.

NERC and the eight regional entities are often referred to as the ERO Enterprise, which collectively brings together the leadership, experience, judgment, skills, and supporting technologies of NERC and the regional entities to fulfill the electric reliability organization’s statutory obligations to assure the reliability of the bulk power system.

Chapter: 5 The Energy Policy Act of 2005

FPA Section 215

Purpose and Scope

Following the August 2003 blackout, Congress enacted the Energy Policy Act of 2005 (EPAct 2005), which President George W. Bush signed into law on August 8, 2005. Title XII of EPAct 2005 added a new section 215 to the FPA, titled “Electric Reliability.” Section 215 of the FPA does not prohibit or otherwise “outlaw” blackouts. Instead it authorizes FERC to certify an entity to operate as an in- dependent electric reliability organization to develop and enforce mandatory Reliability Standards that “provide for reliable opera- tion of the bulk power system,” subject to FERC oversight. More- over, the statute does not pertain to outages on the distribution system that may occur, for example, when a tree falls on a local distribution wire. Rather, section 215 of the FPA makes clear that the Reliability Standards are to address the reliable operation of the bulk power system so that “instability, uncontrolled separation, or cascading failures” will not occur as a result of a sudden disturbance. This mandatory approach replaces the electric industry’s voluntary protocols and guidelines for operating and planning the bulk power system that had been in place since the 1960s.

Following the August 2003 blackout, Congress enacted the Energy Policy Act of 2005 (EPAct 2005), which President George W. Bush signed into law on August 8, 2005. Title XII of EPAct 2005 added a new section 215 to the FPA, titled “Electric Reliability.” Section 215 of the FPA does not prohibit or otherwise “outlaw” blackouts. Instead it authorizes FERC to certify an entity to operate as an in- dependent electric reliability organization to develop and enforce mandatory Reliability Standards that “provide for reliable opera- tion of the bulk power system,” subject to FERC oversight. More- over, the statute does not pertain to outages on the distribution system that may occur, for example, when a tree falls on a local distribution wire. Rather, section 215 of the FPA makes clear that the Reliability Standards are to address the reliable operation of the bulk power system so that “instability, uncontrolled separation, or cascading failures” will not occur as a result of a sudden disturbance. This mandatory approach replaces the electric industry’s voluntary protocols and guidelines for operating and planning the bulk power system that had been in place since the 1960s.

The statute contemplates an electric reliability organization that lever- ages the expertise of the industry in developing Reliability Standards. EPAct 2005 requires that the electric reliability organization have an independent governing board, without financial ties to the users, owners and operators of the bulk power system. At the same time, the electric reliability organization must have rules that provide for fair stakeholder representation in the selection of its directors, and there must be bal- anced decision-making in the electric reliability organization’s commit- tees. The electric reliability organization must provide “reasonable notice and opportunity for public comment, due process, openness, and balance of interests” in devel- oping Reliability Standards and otherwise exercising its duties.

The electric reliability organization develops and enforces Reliability Standards that provide for an “adequate level of reliability” of the interconnected transmission network.

FERC only approves Reliability Standards that are applicable to registered entities in the contiguous United States. Governmental organizations outside of the United States, but in North America, can also approve NERC’s standards for applicability in their respective countries. Under section 215 of the FPA, NERC develops the Reliability Standards, not FERC. Once NERC develops a Reliability Standard, FERC may approve the standard or remand the standard to NERC. FERC also has authority to direct NERC to develop a new or modified Reliability Standard that addresses a specific reliability matter. FERC does not have the authority to write a Reliability Standard.

FERC must approve a Reliability Standard before it may be enforced in the United States. An approved Reliability Standard may be enforced by NERC, and NERC’s enforcement of a Reliability Standard is subject to FERC’s review. FERC also may initiate a compliance action – including imposition of a penalty – independent of NERC.