Chapter: 1 Introduction

Solar thermal systems are commonly used for the domestic water heating, space heating, (industrial) process heating, and even for cooling of goods and buildings. The Energy Independence and Security Act (EISA) 2007 SEC. 523 requires that “if lifecycle cost-effective, as compared to other reasonably available technologies, not less than 30% of the hot water demand for each new Federal building or Federal building undergoing a major renovation be met through the installation and use of solar hot water heaters.” In the United States, different types of solar water heating systems are available and primarily used for standalone buildings. Different design guidelines are available from the National Renewable Energy Laboratory (NREL) and American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) for small size systems. These systems are relatively complex and application of solar based heating in the United States is often limited by economical considerations when compared to traditional heating systems and local cost of fossil fuels.

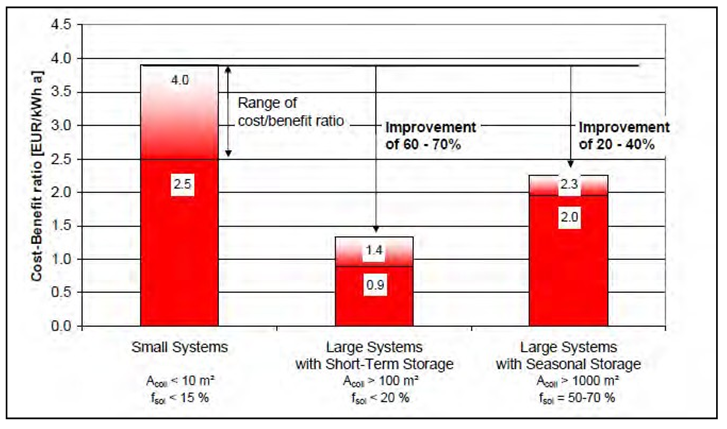

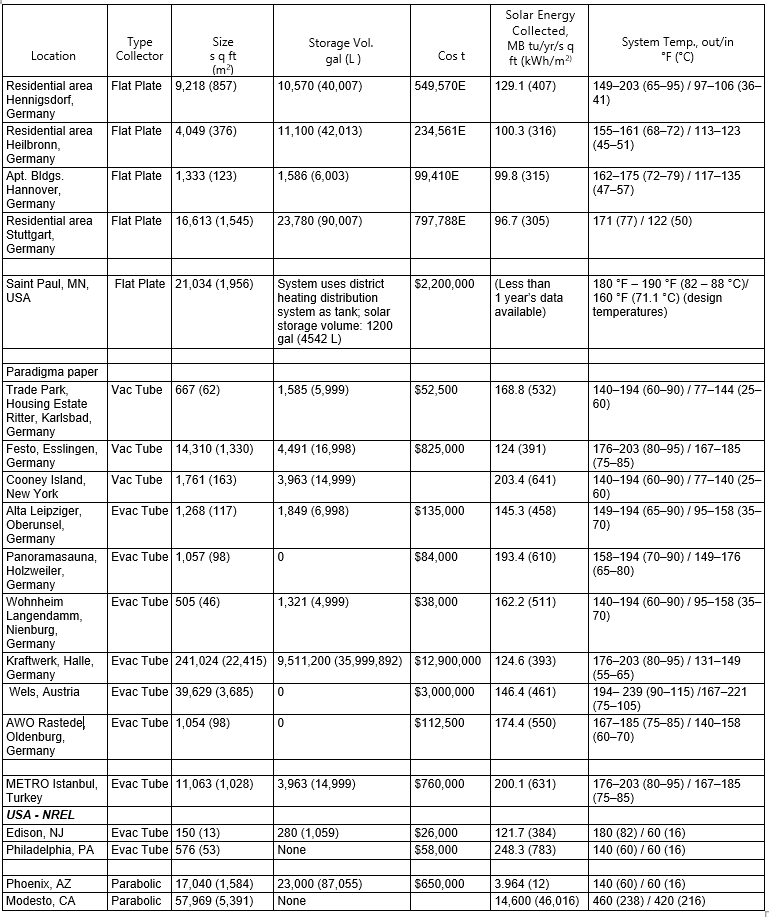

In recent years, numerous innovations in solar thermal technologies have resulted in cost effective large scale systems including integrated solar supported heating networks. Examples of such systems installed in Denmark, Germany, Austria and other countries have proven that such systems are reliable and may be more economical compared to small scale systems. Such systems may be cost effective for clusters of buildings containing e.g., Army barracks, dining facilities, gyms, child development centers and swimming pools. Similar opportunities exist on large hospital campuses, family housing complexes, etc.

This course will assist an engineer with recommendations on optimal and reliable configurations of solar water heating systems in different climates along with design specifications, planning principles, and guidelines for such systems that serve building clusters with significant domestic hot water (DHW) needs (e.g., homes, dining facilities, Child Development Center [CDC], Gyms) that operate in combination with central heating systems. Note that, throughout the industry, the terms “district heating system” and “central heating system” are commonly used interchangeably. For the purposes of this course, the term “Central Solar Hot Water System” is used to denote systems that serve clusters of buildings from a large centralized solar thermal field(s) (in contrast with small size solar thermal systems that serve standalone buildings). The guidelines are complemented by numerous case studies of successfully implemented solar supported thermal networks along with results of exemplary simulations of different system options based on real world scenarios. This course also discusses the benefits and disadvantages of large scale centralized versus decentralized solar thermal systems.

Chapter: 2 Solar Energy

2.1 Solar radiation intensity

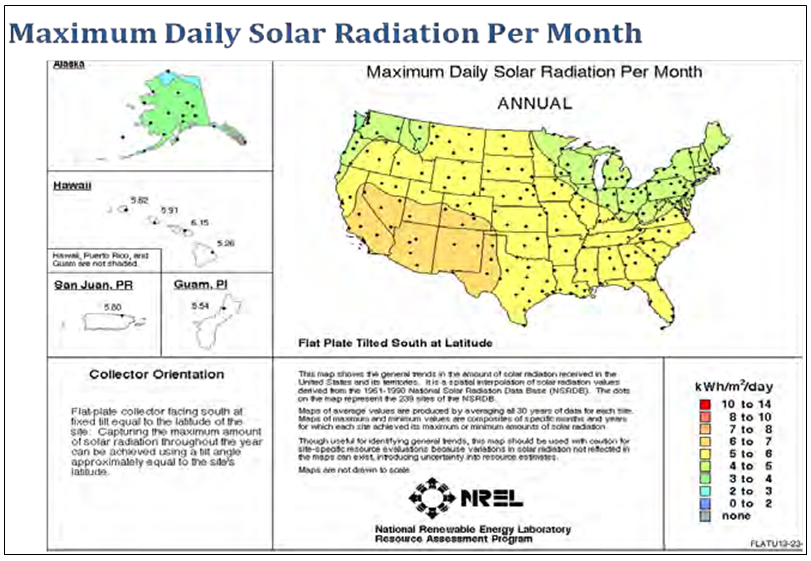

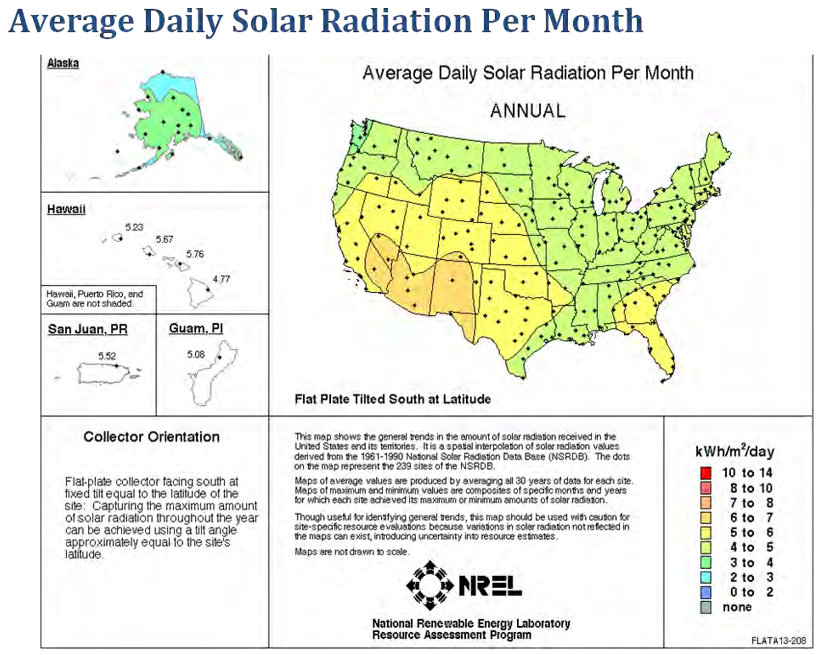

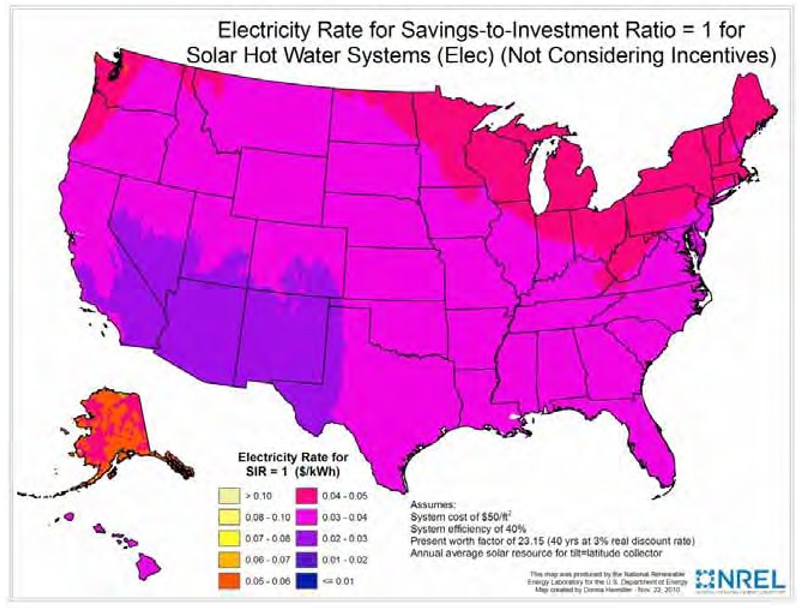

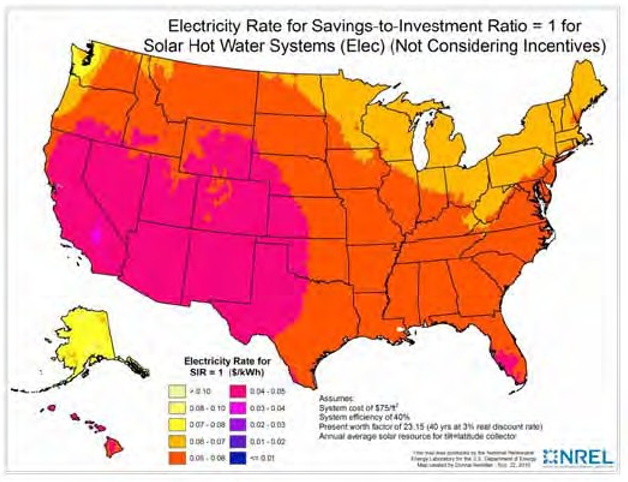

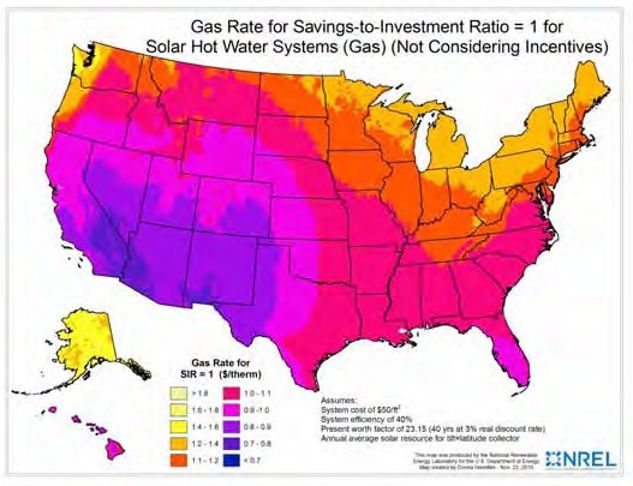

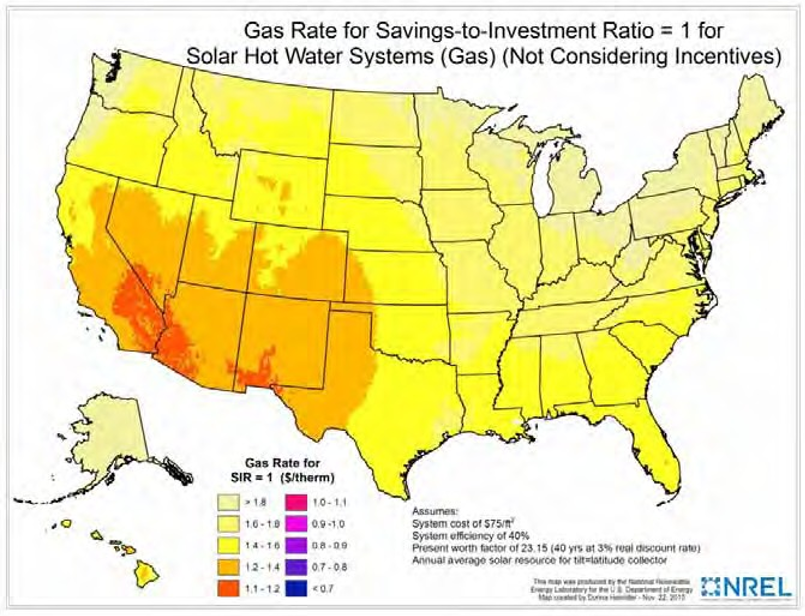

The efficiency and performance of solar water heating systems depend on a site’s solar energy resource. Solar resource is measured by the solar radiation intensity of an area, but cloud cover and latitude must also be factored into the system purchase decision. The amount of solar energy available for heating water varies by geographical location. Figures 2.1 and 2.2 show that tilted flat plate collectors located in the United States at an angle equal to the latitude receive the most sunlight in the desert Southwest and the least sunlight in the Pacific Northwest and states in the Northeast. Table 2.1 lists the maximum daily solar radiation and average daily solar radiation for selected US locations. Detailed monthly solar radiation information for a multitude of locations in the United States is available from the National Renewable Energy Laboratory at:

2.2 Cloud cover

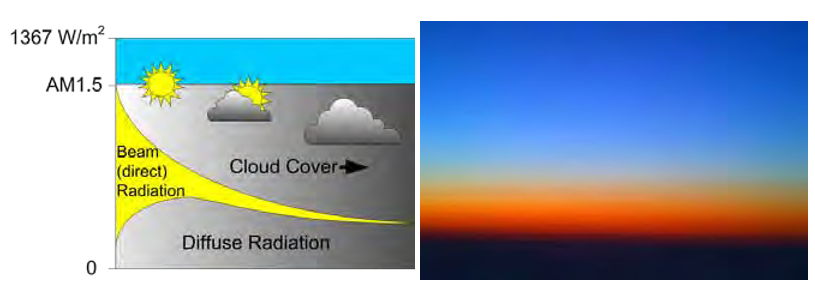

The power of solar radiation entering the atmosphere, or the “solar constant,” is 1367 W/m2 (50,169 Btu/hr/sq ft). Within the atmosphere, this power is reduced by absorption, scattering, and reflection effects to about 1000 W/m2 (36,700 Btu/hr/sq ft) on the earth’s surface if there is a clear sky (Figure 2.3). The solar radiation that reaches the earth’s surface is further reduced by clouds,

which reflect part of the radiation back into space, and absorb another part. In addition, a part of the radiation is dispersed into diffuse radiation by multiple reflections. Diffuse irradiation on the earth’s surface consists of the irradiation coming from angles different than the solar incidence angle (i.e., the actual sun position). Therefore, cloud cover reduces the total amount of irradiation (global radiation), and (due to scattering), it also changes the relation between beam and diffuse radiation. As cloud cover changes with the seasons, these effects are also seasonal dependent. The diffuse fraction of the total annual global radiation can be higher than 50%, depending on the location.

Even on a clear day a significant amount (>10%) of solar radiation is scattered due to the effects of molecules in the atmosphere. This causes the sky at daytime to appear blue and colors the sun red at sunset, when the distant light waves that enter the atmosphere are longer.

2.3 Site latitude

The latitude of the site will affect the solar radiation collected, so it is important to tilt panels based on the latitude of the installation site. The United States lies closer to the middle latitudes, which means it receives more solar energy in the summer when the sun’s path is most perpendicular to locations below. The sun slants far south during the shorter days of the winter months when the sun follows a southern path in the sky. For this reason, solar collectors should face true south in the northern hemisphere, i.e.:

2.3.1 Season of year

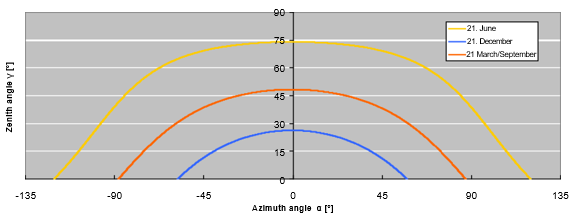

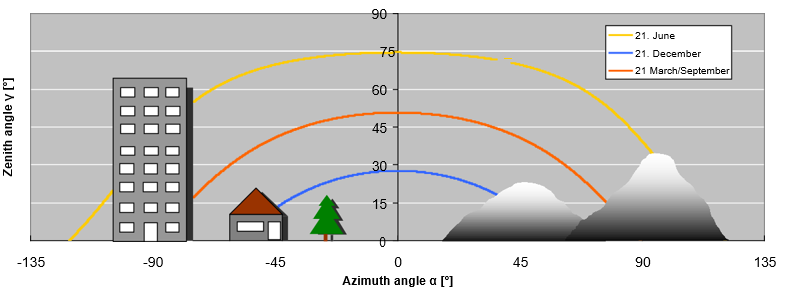

The height of the sun’s travel on the horizon varies by season of the year. In the summer, it is more directly overhead; in the winter, it is much lower. Figure 2.4 shows the different paths* of the sun over the sky for Washington, DC. The maximum incidence angle during (solar) noon for the location in this example is 75 degrees on the 21st of June (the summer solstice). The minimum incidence angle occurs on the 21st of December (the winter solstice). And the average incidence angle occurs on the 21st of March and the 21st of September (the autumnal and vernal equinoxes). For locations further north, these curves will be flatter, and for locations further south, steeper.

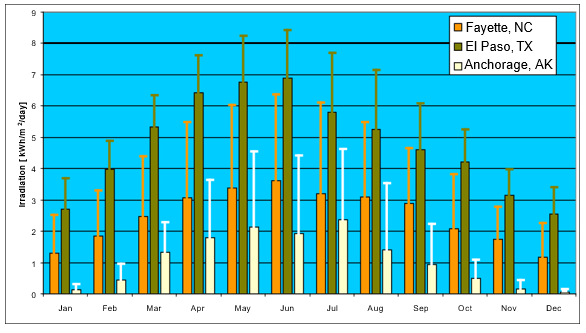

Thus, the amount of solar energy that can be collected varies throughout the year. Monthly available solar radiation values are used to determine the size of the solar collector system required to satisfy the heating demand. Figure 2.5 shows the variation of beam and diffuse radiation over the year for three locations. (The values apply to a collector surface tilted 40 degrees south facing.)

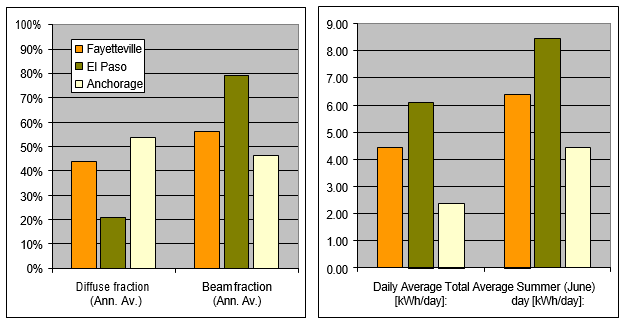

The sum of beam and diffuse radiation falling on a horizontal surface is usually called “global solar radiation.” The annual total in the figure above, 40-degree tilted south facing, for Fayette NC is~507,504 Btu/y*sq ft (~1600 kWh/y*m2); and for El Paso, TX, 697,818 Btu/y*sq ft (2200 kWh/y*m2); and for Anchorage, AK, 272,783 Btu/y*sq ft (860 kWh/y*m2). This results in an annual daily average of 1,396, 1,935, and 761 Btu/sq ft*day (4.4, 6.1, and 2.4 kWh/m2)*day respectively. The fraction of diffuse radiation is 44%in Fayette, 21% in El Paso, and 53% in Anchorage. Day and seasonal variation can be very high; a nice summer day may provide as much as 2,030.02 Btu/sq ft*day (6.4 kWh/m2)*day in Fayette and 2664 and 1459 Btu/sq ft*day (8.4 and 4.6 kWh/m2 *day) in El Paso and Anchorage and a cloudy winter day may have as little as 63.44 Btu/sq ft*day (0.2 kWh/m2*day) on average in the month of December in Anchorage (Figure 2.6).

2.3.2 Solar collector tilt

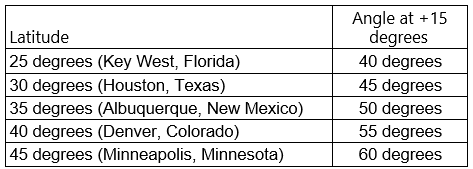

Solar systems should be designed to match the heating demands with the solar energy intensity that varies throughout the year. In the northern hemisphere, a solar thermal system will receive less solar radiation in the winter than in summer. To improve the seasonal solar energy collection, the solar collector can be tilted so that it would be more perpendicular to the sun’s path when the heating demand is greatest. Tilting of collectors (from horizontal) should be done to maximize the radiation collection skewed for usage. Thus a system that is providing heat for the winter should have a tilt angle equal to the site’s latitude, plus up to 15 degrees; a system for year round heating should have a tilt angle equal to the site’s latitude. Table 2.2 lists collector tilt angles at selected locations for maximizing winter solar energy collection.

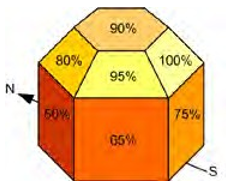

Maximum radiation can be collected when the collector is faced due South in the Northern Hemisphere. If the system must be East or West facing, using a Westerly azimuth is more optimal than an Easterly one since the collector can take advantage of the warmer part of the day.

2.4 Orientation to path of sun

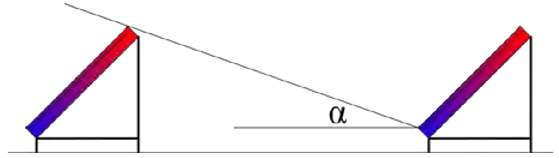

Two angles describe the orientation of the collector:

- The azimuth* angle α, also called “compass orientation”: The angle in a horizontal surface between the collector and the due south direction. Due south, towards the equator, is by definition an orientation of 0˚.

- The tilt angle β (“sky ward orientation”): The angle between the collector and the horizontal surface.

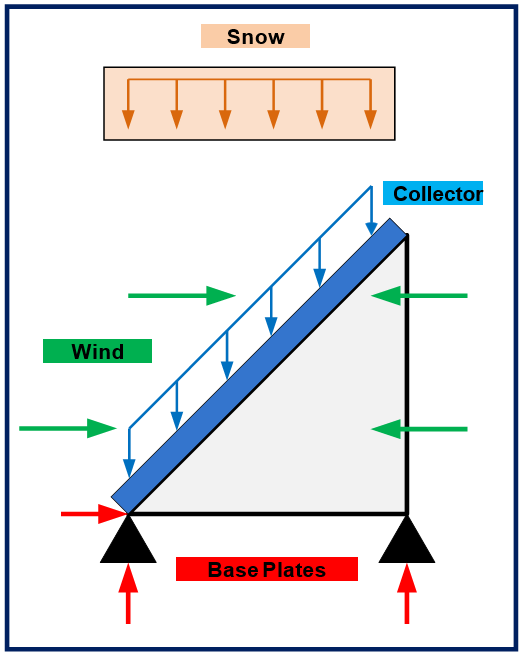

Costs for supporting structures can be saved by mounting collectors flush with an existing, suitable surface or structure. Tools (brackets etc.) are usually available from the supplier of the collector, which will suit various common surface types like tiled or sheet metal roofs, brick or wood walls etc. The fittings should provide sufficient strength to endure extreme weather conditions like wind and snow loads. It is important that the mounting and structure comply with local standards and regulations.

If mounted in line with an existing structure (e.g., a wall surface) the orientation may be less than optimal, in many cases. The effects of these compromises are often less than expected. This is shown in Figure 2.7. A deviation from the maximum yield tilt and orientation can be compensated for by a larger collector area, if space and costs permit.

A rule of thumb for optimum exposure to solar radiation is that a collector should face the equator (orientation of 0 degrees, due south) with a tilt angle of 0.7 times the Latitude of the location (but at least 10 degrees, or the minimum working angle of the collector). This applies to heating domestic water systems.

The optimum collector tilt angle for the usage of solar energy during winter months is higher because the average sunlight incidence angle is lower. Choosing a larger tilt angle provides a yield that is geared towards winter heat demands. The optimum collector tilt angle for the winter months is higher than the latitude, for example 50 degrees for a site at 45 degrees latitude. Deviations up to 60 degrees from these optimum angles generally will lead to a loss of solar radiation of less than 15% compared to optimum angles. Note that the annual yield also depends on many other factors such as the heat demand characteristics or the storage capacity.

Choosing a smaller tilt angle gears the yield towards the summer. Usually a summer bias increases the potential overall annual yield of a collector, but only if this extra yield can be used. Solar thermal systems are thus often sized by matching the collector yield during the summer period with the hot water heating need (called economical collector sizing), any increase in collector area will increase the fraction covered in winter, but will also increase the stagnation periods and duration during summer. Refer to Section 3.4.2 (p 33) for an explanation of stagnation.

2.5 Shading

Shading causes less radiation to reach the collector surface. The positioning decision of the collector may be influenced by anything that can cause shade on the collector surface such as mountain ranges on the horizon, nearby or tall buildings, nearby trees (in particular when carrying leaves during winter), and nearby roof construction. Local fog conditions can also cause a loss in sunlight. Shading should be avoided during the peak sun hours of the day, 9 a.m.–3 p.m.

The loss of incoming radiation due to shading must be taken into account during simulations for calculating the prospective yield and usually involves mapping the obstacles on the horizon and sky in the face of the collector orientation (Figure 2.8).

Causes of shade such as fallen leaves and snow depend on location and climatic conditions and should also be considered.

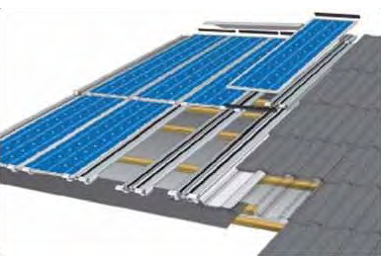

2.6 Collector placement within a building cluster

The solar collectors can be placed on buildings or on the ground. In some cases they could be placed in an elevated position over parking lots providing shade below as an additional benefit. Placement on a building is normally on the roof where a sloped or flat roof exists. Placement on a sloped roof normally creates a collector tilt similar to that of the roof. Also, the orientation may not be directly to the south. In these cases, heating energy obtained from the collector must be derated from that of an optimum placement. Such a placement normally gives a better appearance than that of tilted collectors on a flat roof. Building integrated collectors are assimilated into the original construction of the roof or can be placed slightly above the pitched roof. In either case, the collectors will use the structure framework of the roof as the main support.

The most important considerations for collector placement is to encourage integration in existing infrastructure, and to avoid shading at periods when solar radiation is plentiful and heating is needed. For large central systems the option of creating a large collector field is usually chosen. This system can be integrated with carport roofing or placed on the flat roof of a large building.

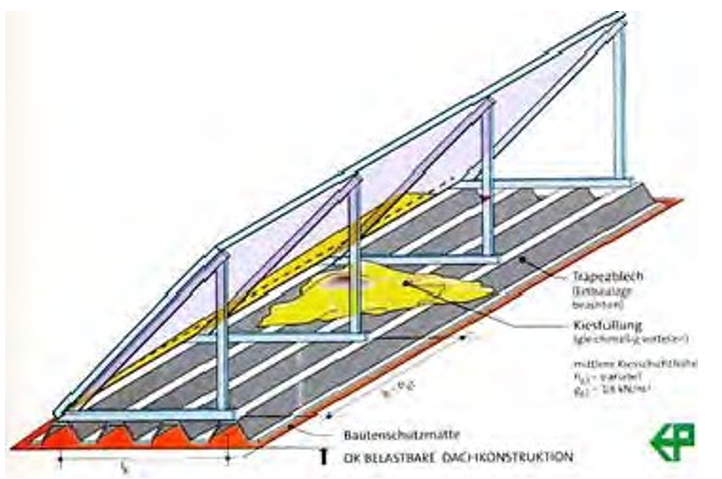

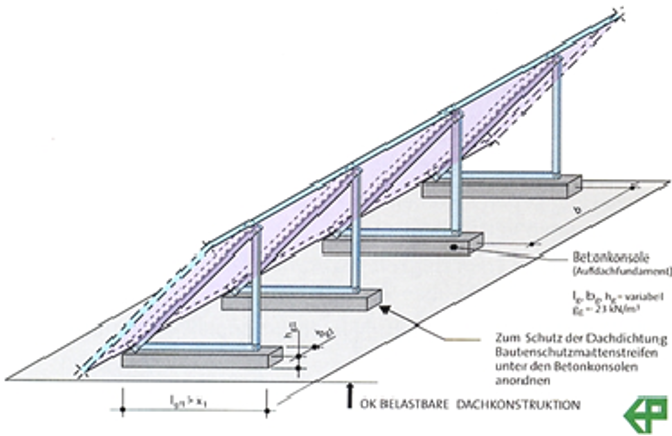

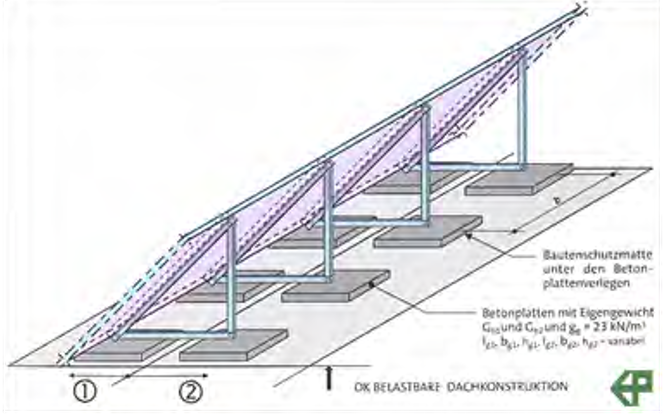

Figures 2.9 and 2.10 show examples of installed collector fields. Integration into new building structures may be more aesthetic and may provide for savings in roof cover material otherwise used. Specially constructed flat plate collectors can provide a closed, insulated surface, which may serve as a roof cover (Figure 2.11).

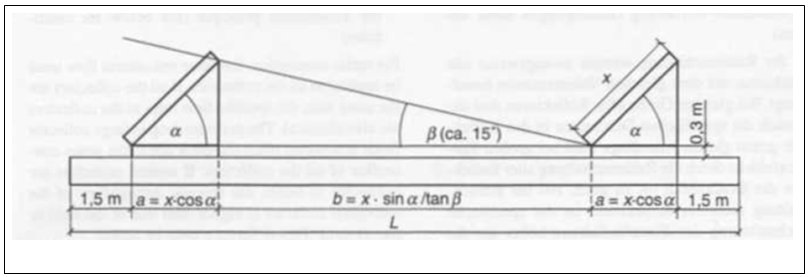

Collectors placed on the ground or on flat roofs need a supplemental support to generate the collector tilt to the sun. The rows of collectors must be separated by a short distance so that one row does not shade the row behind it. The distance to assure no shading on the winter solstice can be calculated by:

Separation distance = collector height X tangent of the angle (90 – latitude- 23.5)

Since the energy collected in the winter is a small percentage of the total, then the spacing between rows can be slightly reduced with only minor loss in performance. Figure 2.12 shows how the winter midday sun-angle is (usually) used to determine the angle.

Chapter: 3 Solar Hot Water Thermal System

The main components added to a conventional heating system when solar thermal energy is used are:

- collector field with collector field piping and support structure

- heat transfer fluid (water or water glycol mixture)

- a storage tank system

- pump for solar loop and other pumps for other loops

- heat exchangers to transfer heat from one loop to another

- expansion and safety devices for each closed loop

- a controller with temperature sensors in collector field and storage tank and that turns the pump on and

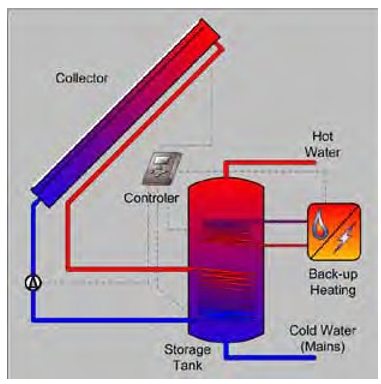

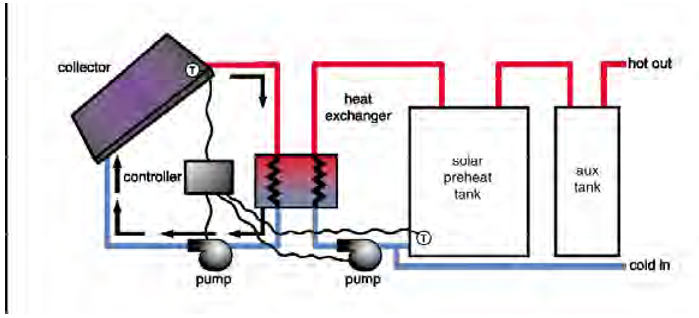

Since a solar thermal system does not usually act as the main heat source, an auxiliary (back-up) heater is necessary to cover periods of high energy demand or too little solar radiation (usually in winter). Figure 3.1 shows a schematic of a solar domestic hot water system.

3.1 Collector performance indices

Various performance characteristics are used to assess and compare solar thermal systems. The most important ones are the “solar fraction” (SF), the “specific solar energy yield” (SE), and the “solar system efficiency” (SN). The following sections discuss these indices.

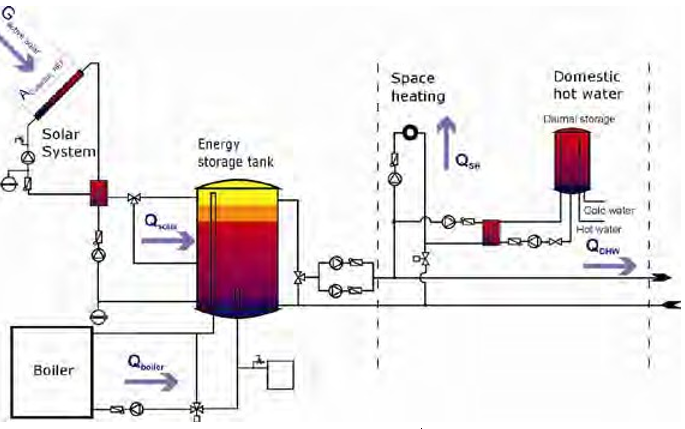

To ensure that the reference quantities and energy flows can be clearly assigned, the essential parameters are entered in accordance with their definition and their “position within the system” (Figure 3.2). When selecting the proper components of a large solar hot water thermal system it is best to use analytical modeling tools such as f-Chart or TRNSYS. These computer programs can estimate annual energy collected, storage and heat exchanger effects, system heat losses, etc. Refer to Section 3.3.2 (p 23) for information regarding these modeling tools.

3.1.1 Solar fraction (fsolar or SF) and Fsave

A commonly used solar system performance measure is the solar fraction, which identifies the fractional amount of the building heating energy needed is supplied by the solar thermal system. This Design Guide defines the solar fraction for solar supported heating networks as:

Thus, a building that requires 10.24 MBtu (3000 kWh) per year to generate hot water and obtains 6.83 MBtu/yr (2000 kWh/yr) from its solar system has a solar fraction of 67%. A very similar indicator is the “f-save” ratio. This indicator shows the thermal heating energy saved by the supply of solar energy as compared to the heating energy that would have been used by a non-solar thermal (reference) system for the same purpose. For example, when a non-solar heating system (the reference system) requires 10.24 MBtu/yr (3000 kWh/yr) to provide for a certain hot water use, and the solar thermal system requires 6.8 MBtu/yr (2000 kWh/yr) auxiliary heating, then the f-save of the solar thermal system is 33% (i.e., the fraction of auxiliary energy saved compared to the reference system). The formula for f-save (thermal) is:

For both indicators it must be specified whether direct energy (heating energy demand), primary energy, or secondary energy is used in their calculations. The major difference is what is included in the building heating energy use (the reference system) and the impact of thermal system losses and supporting equipment energy use such as by pumps, etc.

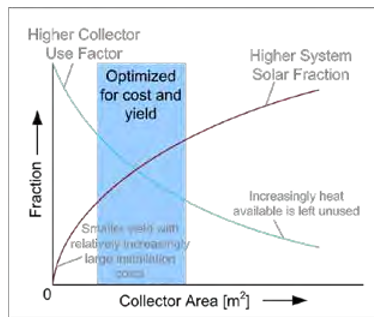

Higher solar fractions mean higher energy and CO2-savings relative to the conventional energy source. However, one must also consider that the higher losses of the solar thermal system negatively affect the solar system efficiency. An economic optimum has to be found.

3.1.2 Solar system efficiency (SN)

In addition to the solar fraction, economic investigations of solar thermal systems are often affected by another parameter, the solar system efficiency (SN). The solar system efficiency describes the ratio between the annual amount of energy supplied to the heat storage unit and the global irradiation that strikes the collector surface:

3.1.3 Specific solar energy yield (SE)

The specific solar energy yield describes the annual amount of energy supplied to the heat storage unit from 11 sq ft (1 m2) of collector surface area. Compared to other calculation results, the kind of surface (absorber, aperture or gross collector area) must always be indicated for the specific yield result.

The specific solar energy yield is often said to be the crucial parameter for measuring the capacity of a solar energy system. For a correct interpretation of this parameter, the size of the system, the solar fraction and the system losses (storage and heat distribution losses) must be considered. Solar collector ratings provided by Solar Rating and Certification Corporation and the Florida Solar Energy Center use the gross area of the collector (not the net area) in their performance efficiency rating information. ASHRAE Standard 93-2010 (for testing to determine thermal performance of solar collectors) also uses the gross area of the collector.

3.1.4 Collector testing and certification organizations

Several organizations provide certification of solar collector and solar collector system performance in the United States, the most recognized of which are:

- Solar Rating and Certification Corporation (SRCC). This is the principle rating organization for solar domestic hot water collectors. The SRCC offers OG-100 certification for solar collectors and OG-300 for entire systems. OG-300 certification is for smaller residential systems.

- Florida Solar Energy Center (FSEC). Mandated by the state of Florida to perform testing of solar energy products, the FSEC is a good source for performance characteristics on both solar thermal collectors and entire solar thermal systems. Although specifically geared towards the solar industry in Florida, the FSEC is a good resource for the Southeast region as a whole. FSEC Standard 101-09, which was revised May 2009, is the institute’s solar collector certification. It supersedes FSEC Standard 102-05.

- North American Board of Certified Energy Practitioners (NABCEP). The NABCEP provides certification programs for solar electric and thermal system installers. A NABCEP-certified installer provides for an extra level of assurance as to the qualifications of the installer. However, because the solar thermal certification is a relatively recent development, NABCEP- certified installers are not especially common.

3.2 Types of hot water solar systems

3.2.1 Passive systems

“Passive” systems solar hot water systems do not have a pump or other moving parts. These heating systems rely on temperature changes in the water located in the solar collectors on the roof to move the water through the system. They are typically less expensive than systems having a pump (active systems) because they have no mechanical parts, but they are usually not as efficient. However, passive systems can be more reliable and may last longer. There are two basic types of passive systems: batch and thermosiphon.

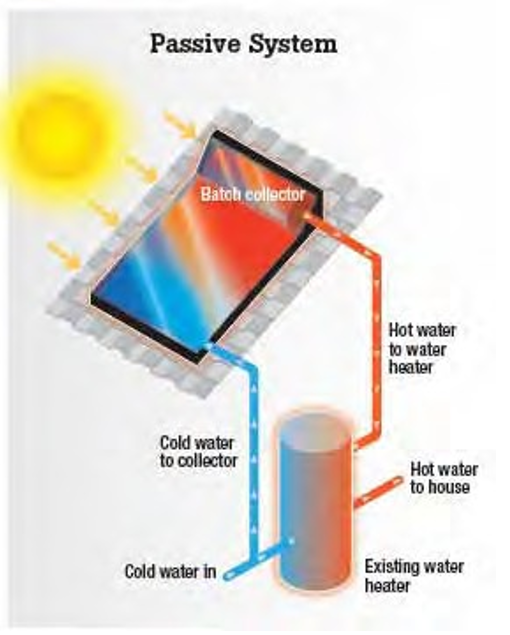

Batch or Integrated collector-storage (ICS) systems. These systems work best in areas where temperatures rarely fall below freezing. They also work well in buildings with significant daytime and evening hot-water needs. Batch collectors (Figure 3.3) or ICS, use one or more black tanks or tubes in an insulated, glazed box. Cold water first passes through the solar collector and is preheated.

The water then continues on to the conventional backup water heater, providing a reliable source of hot water. This type of collector should be installed only in mild-freeze climates because the outdoor pipes can freeze in severely cold weather.

Thermosiphon systems. Thermosiphon systems (Figure 3.4) move water through the system due to density differences (warm water rises as cooler water sinks). Neither pumps or electricity are used. However, the collector must be installed below the storage tank so that warm water can rise into the tank. These systems are reliable, but contractors must pay careful attention to the roof design because of the heavy storage tank. Although they are usually more expensive than ICS systems, they can be used in areas with less sunshine.

Passive solar water heating systems are used on individual buildings or for a single heating demand. They are not for central heating systems that service several buildings. They are also inefficient in cooler climates. Since the purpose of this design guide is to focus on systems that can serve multiple buildings, these systems will not be further discussed.

3.2.2 Active systems

Solar water heating systems that rely on electric pumps to circulate fluid through the collector are called “active systems.” Active systems are generally categorized into two types: direct and indirect, which simply means that water in the storage tank is either directly filled using the hot water flowing from the solar collectors (one loop) or indirectly using two water circulating loops separated by a heat exchanger. The latter type is normally used in locations where outdoor winter temperatures below freezing may occur. These systems use an anti-freeze solution such as a water glycol mixture as a heat transfer medium that circulates through the collectors to avoid freezing.

Direct circulating active system (no anti-freeze). These systems use pumps to transfer the sun’s energy directly to potable water by circulating this water through the collector tubing and storage tank; no anti-freeze solution or heat exchanger is used. The pumps circulate water through the collectors, into the building, and back again. They work well in climates where it rarely freezes.

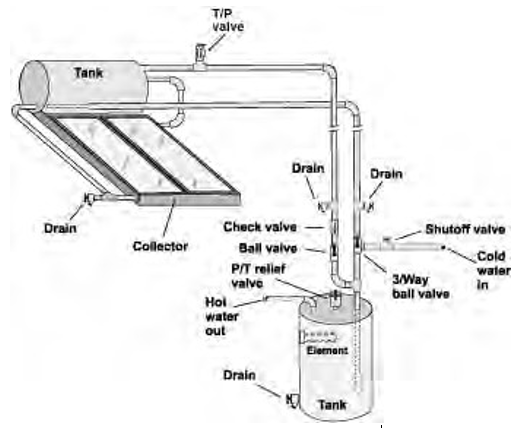

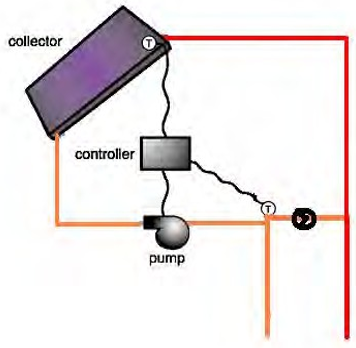

A direct active system (Figure 3.5) has one or more solar energy collectors installed and a nearby storage tank. The system uses a differential controller that senses temperature differences between water leaving the solar collector and the coldest water in the storage tank. When the water in the collector is about 15 to 20 °F (-9 to -7 °C) warmer than the water in the tank, the pump is turned on by the controller. When the temperature difference drops to about 3 to 5 °F (-16 to -15 °C), the pump is turned off, so the stored water always gains heat from the collector when the pump operates. A flush-type freeze protection valve installed near the collector provides freeze protection. Whenever temperatures approach freezing, the valve opens to let warm water flow through the collector. The collector should also allow for manual draining by closing the isolation valves (located at a height above the storage tank) and opening the drain valves. Automatic recirculation is another means of freeze protection. When the water in the collector reaches a temperature near freezing, the controller turns the pump on for a few minutes to warm the collector with water from the tank.

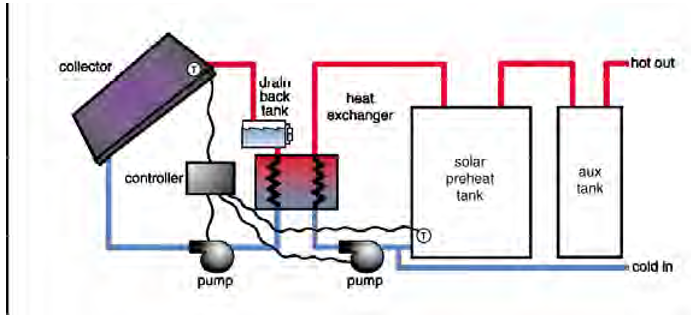

Another type of direct active solar water heating system is called “a drainback-system” (Figure 3.6), which is also designed for cold climates. This type of system typically uses regular water as a heat transfer fluid, and is designed to allow all of the water in the solar collector to “drain back” to a holding tank in a heated portion of a building. When no sunlight is available for heating, the solar pump turns off and the water flows into the drainback tank by means of gravity. Since these systems use water, they can be designed with or without a heat exchanger.

the collector to the water in the storage tank. These systems offer excellent freeze protection, tolerate hard water well, and have high maintenance requirements.

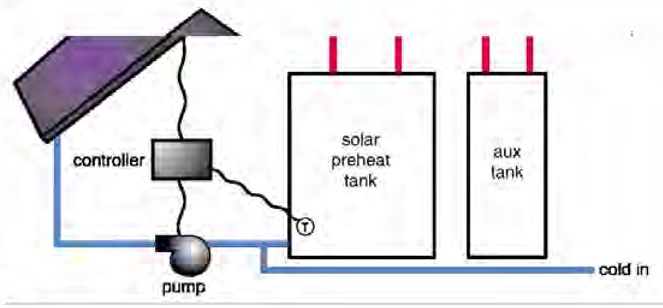

Indirect circulating active system (anti-freeze used). This system operates similar to the direct active system except that there are two circulating heat transfer fluid loops. In the first (solar primary) loop non-freezing, heat-transfer fluid such as a water-glycol mixture circulates through the collector field. A heat exchanger transfers the heat from the water-glycol mixture into the potable water. The heat exchanger can either be directly integrated into a storage (internal heat exchange) or the storage can be connected to a second loop (solar secondary loop) via an external plate heat exchanger (Figure 3.7). These systems are popular in climates that are prone to freezing temperatures.

If the solar collector is extremely well insulated and is not prone to freezing like an evacuated tube collector, water can be the heat transfer fluid. By using water the heated water from the collector can be sent directly to the storage tank; no heat exchanger is needed. Figure 3.8 shows the portion of this system before the storage tank (and, if used, before the heat exchanger).

Indirect circulating solar water heating systems used on individual buildings or groups of buildings are consistent with the US Army’s needs. They can easily be applied to central heating systems for domestic hot water and building heating. Since the purpose of this design guide is to focus on systems that can serve multiple buildings, these systems will be emphasized in further sections of this course.

3.3 Solar thermal energy collectors

The collector is a key part in a solar thermal heating installation. The following sections discuss the working principle of collectors, and the most common collector types. Most relevant for the application in domestic hot water and space heating systems are glazed flat plate and evacuated tube collectors. A collector should be selected based on the quantity and quality (temperature) of the demanded heat.

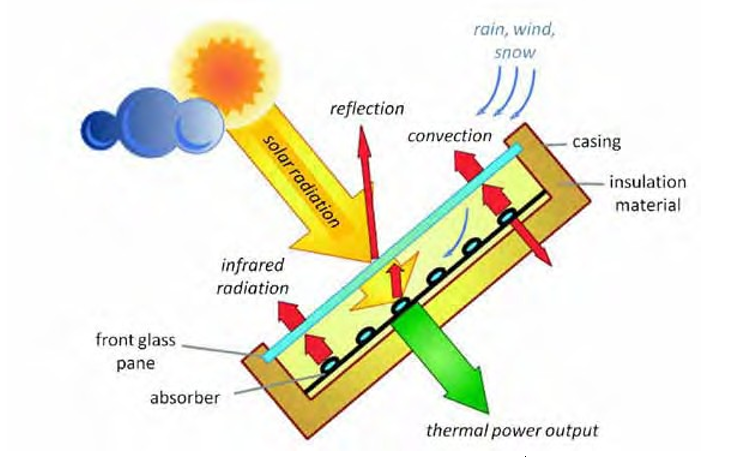

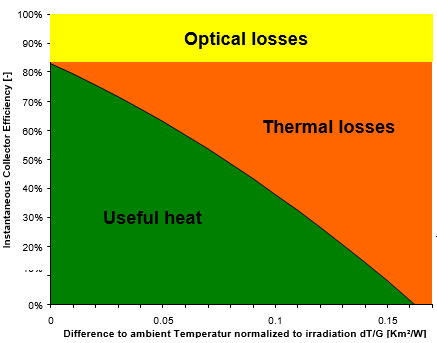

In principle, heat gain and loss mechanisms in different collector types are the same. In general, one differentiates between optical losses (reflection, absorption) and thermal heat losses due to heat transfer mechanisms (conduction, convection and radiation). Figure 3.9 shows the mechanisms for a flat plate collector (FPC).

3.3.1 General construction

Figure 3.9 shows how heat from the sun is collected by the absorber and is carried away by the fluid flowing through the tubes attached to the absorber. Since these collectors are located outside and normally in a cooler environment, the heated absorber can lose heat its surroundings. To reduce this heat loss, a cover is placed over the absorber and the sides and back of the absorber are insulated. The cover must allow solar radiation to penetrate and, since glass is typically used, some of this radiation will be reflected and radiated out to the atmosphere. The following sections will provide a brief overview and details of the solar collector parts.

3.3.1.1 Absorber

The function of the absorber is to effectively convert solar radiation into heat. The absorber surface is often coated to maximize this energy collection. The absorber coating is thus designed with a high absorption coefficient, a, for the sun’s radiation spectrum (typically a = 0.92 to 0.96).

Absorptivity is the fraction of incident sunlight captured (not reflected) by the absorber. The reflectance is the complement of the absorption and is given by: ρ= 1 – α. For best performance, the absorber should have a low emission coefficient ε (typically, ε = 0.05 to 0.1) for infrared radiation to keep the losses from long wave radiation emission low as the collector heats up.

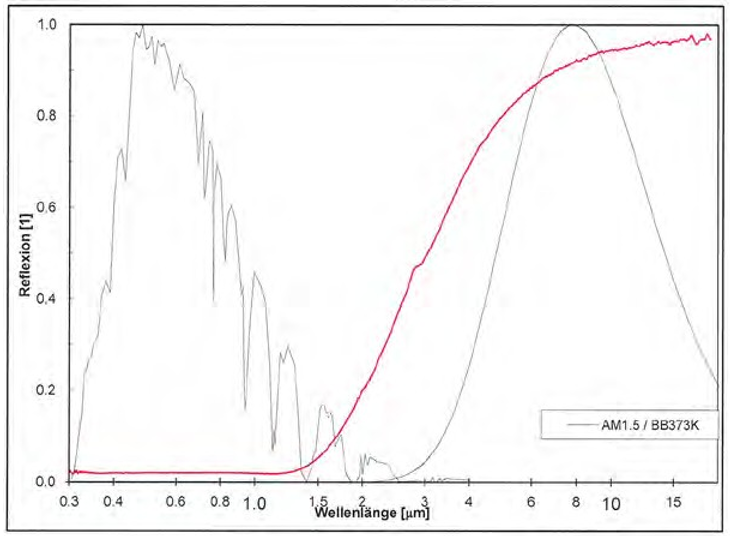

Emissivity is the ratio of radiant heat loss off the absorber relative to that of a perfectly black surface (“blackbody”). Most common materials, such as black paint, have an absorptivity equal to the emissivity, and the second law of thermodynamics requires that all materials have a=e at a given wavelength of incident light. However, special surface treatments (semiconductor coatings, blackened nickel layer) have an absorptivity in the short-wavelength solar spectrum that is much higher than emissivity in the long-wavelength infrared radiant heat loss spectrum. Such surfaces are called “selective surfaces” and improve the performance of solar collectors, especially when operating at elevated temperatures where radiant heat loss is more important.

Absorber coatings that possess high absorptivity and low reflectance are called “selective absorbers.” Figure 3.10 shows this selective effect where the absorption/reflection characteristics of a selective surface are identified at various wavelengths of the solar spectrum. These wavelength values are taken with an atmospheric thickness of 1.5 of the thickness taken directly above (AM = 1.5). This is important since the atmosphere affects the spectral nature (wavelength distribution) of the solar radiation, and properties reported at AM=1 refer to one thickness of atmosphere. If the sun is not directly overhead, the sun’s rays will have to go through more than one thickness of atmosphere. For example, AM = 1.5 corresponds to a zenith angle of around 48.2 degrees, and AM=0 refers to the wavelength outside of the earth’s atmosphere.

spectral reflectivity (Reflection) of a s elective absorber is indicated by the red line.

For spectral irradiance originating from the sun the solar constant (1.367 W/m2) is defined as AM = 0. AM = 1 is defined as the spectral irradiance on a horizontal plane (zenith angle = 0°). AM = 1.5 is equal to a zenith angle of around 48.2 degrees and the global radiation accounts for 36,700 Btu/hr/sq ft (1000 W/m2). (Tables of these standard spectra are given in ASTM G 173-03. The extraterrestrial spectral irradiance (i.e., that for AM0) is given in ASTM E 490-00a).

3.3.1.2 Transparent cover

The purpose of the transparent cover is to reduce the convection losses from the absorber, while allowing the maximum amount of radiation to reach the absorber. The cover must also provide the mechanical strength to protect the absorber from the environment.

Special solar glass with low iron content is used. It is occasionally called “water white glass” and its typical transmittance is t = 0.89 to 0.91 for the wavelength range of the solar radiation. This can be enhanced to t = 0.94 to 0.96 when anti reflective coatings are applied. This glass should be tempered to reduce breakage by impact.

3.3.1.3 Housing

The housing of a collector must provide the necessary mechanical strength to protect the absorber and the insulation to minimize heat loss to the environment. It must withstand wind and snow loads that occur in the area where the collector is installed. It also must be tight enough against rain penetration. These features need to be ensured over the entire lifetime of the system (20 to 25 yrs). Housings are typically made from aluminum sheet stock or extruded sections, galvanized and painted steel, molded or extruded plastic parts, or composite wood products.

3.3.1.4 Insulation

Insulation is added behind the absorber plate and on the sides of the collector to reduce thermal heat losses. The insulation must use a minimum of binders because it is intended for high temperatures (up to about 400 °F [204 °C] for flat plate collector stagnation); otherwise, the binders will outgas and form a film on the underside of the collector glazing blocking solar radiation.

Common insulating materials include, for example, mineral fiber, ceramic fiber, glass fiberglass, and plastic foams. Sometimes polyurethane foam is used, though its resistance to temperature and moisture is limited so it should not be allowed to contact the absorber plate inside the collector. The insulation provides low heat conductivity, some mechanical strength, and temperature and fire resistance.

3.3.2 Types of solar thermal energy collectors

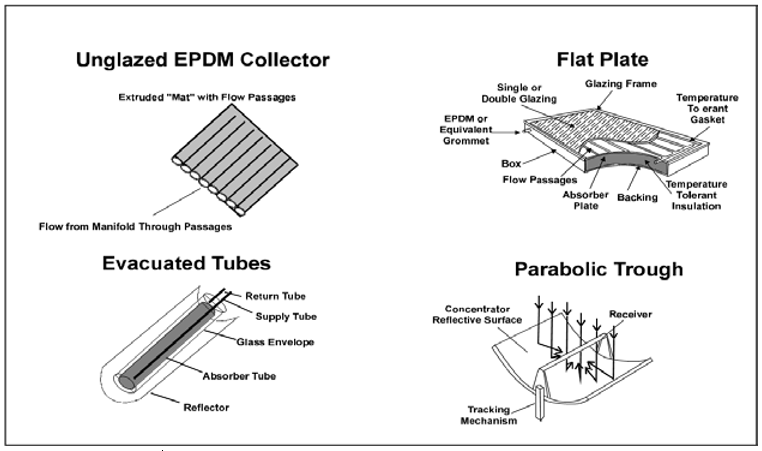

Figure 3.11 shows the four different types of solar hot water collectors. The type of collector chosen for a certain application depends mainly on the required operating temperature and the given ambient temperature range. Due to the design and simplicity of design each type has a maximum temperature that they are best suited to provide:

- Unglazed EPDM* collector – below 90 °F (32 °C)

- Flat plate – below 160 °F (71 °C)

- Evacuated tube – up to 350 °F (177 °C)

- Parabolic trough – up to 570 °F (299 °C).

In the Army, the major hot water requirements are heating for domestic hot water, reheat for humidity control, and building heating. These requirements need a hot water source with a temperature of at least 140 °F (60 °C). This eliminates the unglazed EPDM collector from consideration. The ability of the parabolic trough greatly exceeds these requirements and thus would be a poor selection due to its high cost. This leaves the flat plate and the evacuated tube collectors as appropriate choices for Army applications. Both types of collector would be a good choice for most Army installations, but several factors could influence the selection:

- Cost (from RS Means Green Building Project Planning and Cost estimating, 3rd )-

- Flat plate – ~$17/sq ft = ~129€/m2

- Evacuated tube – ~$24/sq ft = ~182€/m2

- Freeze Protection

- Flat plate – Use non freeze liquid (glycol solution)

- Evacuated tube – some are well insulated so they could use water as collector fluid with the strategy of cycling warm water into the collector from the storage tank if the collector fluid gets too

- Stagnation Issues. Stagnation is caused when the flow through the collector stops and the solar energy heats the collector fluid to extremely high temperatures causing the collector fluid to boil. At what temperature this boiling occurs is dependent on the fluid and the operating pressure on the system. This boiling will push a portion of the collector fluid from the pipes in the collector and can hamper later collector performance. Section 4 (p 32) discusses this topic in more detail.

3.3.2.1 Unglazed flat plate

Unglazed flat plate collectors (Figure 3.12) are usually plastic collectors that are rolled out onto a roof and that are generally used for low temperature heating of such things as swimming pools or preheating of domestic hot water. Due to the absence of a glass cover they have no optical losses and therefore are most suitable for low temperature applications since heat losses increase more with higher temperatures compared to the other collector types. The manufacturers use plastic materials that reduce production and installation costs. Extensive testing and analysis have so far confirmed that the technology meets or exceeds reliability goals. They are generally less expensive, but less efficient than standard solar water heating collectors used throughout all seasons.

3.3.2.2 Glazed flat plate

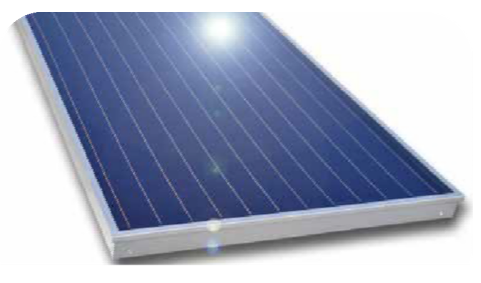

Flat plate collectors (FPC) are essentially insulated boxes that have a flat dark plate absorber that is covered by a transparent cover (Figure 3.13). The solar energy heats the absorber and heat is carried away by a heat transfer fluid that flows through riser tubes that are connected to the absorber. The riser tubes are attached to the absorber in a parallel pattern or they meander from one side to the other.

The cover (usually a sheet of glass) is held in place by a frame above the absorber. The frame also seals the collector at the sides and at the back. It must provide mechanical strength and rain tightness, and must be designed to enable simple roof- and facade attachment or even integration into these building elements. The back and sides of the collector are insulated. Flat plate collectors are usually installed in stationary systems, i.e., they do not rotate to follow the path of the sun. The advantages of flat plate collectors are their simple, robust, low-maintenance design, and their large and effective aperture area.

Flat plate collectors are most commonly used for commercial or residential domestic hot water systems. These collectors generally increase water temperature to as much as 160 °F (71 °C). Special coatings on the absorber maximize absorption of sunlight and minimize re-radiation of heat. These collectors are prone to freezing and in climates where this can occur a mixture of about 60% water and 40% polypropylene glycol is used as the collector fluid (heat transfer medium).

3.3.2.2.1 Design considerations

Flat plate collectors similar to today’s design have been manufactured for over 30 yrs and experience has been gained as to the proper materials to use for best performance and long life. The casing is typically made of aluminum. The absorber plate is made of copper or aluminum; steel is seldom used. To maximize the absorption of the solar energy the absorber plate is typically coated with black chrome, which is a selective covering providing good absorption and weak reflection of solar radiation.

Copper is normally used as the flow channel (tubing) through which the heat transfer fluid flows. It must be well bonded to the absorber plate for good heat transfer. The tubes are commonly placed in parallel rows (as shown in Figure 3.13) where the flow is released in a header at the top of the collector and is collected at the bottom.

Another tube arrangement is for the flow to meander across the surface of the absorber in a back and forth serpentine fashion. In this case the volume of heat transfer fluid spends more time on the collector surface and a greater temperature increase occurs. To obtain proper heat transfer from the absorber to the collector fluid the spacing between the runs of tubing cannot be too great and a tube interval of 4 to 5 in. (102 to 127 mm) is typical. In all cases, the tubes in a collector need to be placed so that the fluid can completely drain from the collector by gravity.

The housing around the absorption plate is mainly to minimize the heat loss to the environment and to provide a weather tight enclosure to prevent corrosion and other types of deterioration. Behind the absorption plate, rock or glass wool, or an insulating foam may be used an the insulating material. Typically a depth of 1-1/2 to 3 in. (38 to 76 mm) of insulating material is used. The insulating material must have the thermal stability to withstand the high temperatures that occur during times of collector stagnation. A glass cover is placed above the absorption plate that allows the solar radiation to pass through while limiting heat loss. Plastic covers deteriorate over time and are not recommended. Double pane glass covers retard the transparency to the solar radiation and thus are not commonly used. For sealing materials, EPDM or silicone rubber type materials should be used as the seal between the casing and the glass cover; adhesives should be silicon based and openings for pipes should be sealed with silicon based products.

3.3.2.2.2 Applications

Flat plate collectors are used mainly for producing domestic hot water and, in some cases, where building space heating is also accomplished. Standard flat plate collectors typically perform best providing hot water below 160 °F (70 °C). There are high performance flat plate collectors (those with a double, anti reflective cover) that perform well providing up to 200 °F (93 °C) hot water.

These are seldom used due to their high cost. Above that temperature, the efficiency drops significantly due to the higher temperature difference between the collector fluid and the ambient air.

It is possible to reduce the thermal heat losses by avoiding convective losses such as by using vacuum tube collectors. The following section discusses this option.

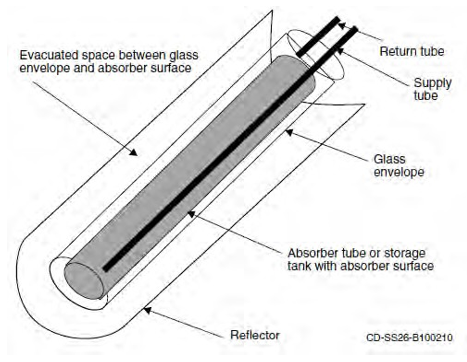

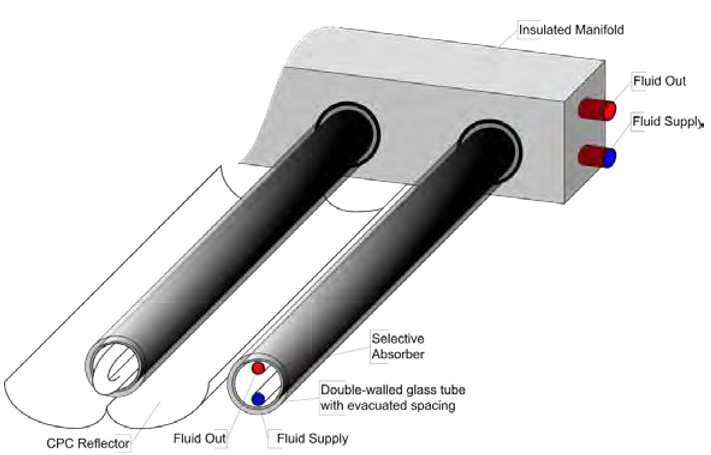

3.3.2.3 Evacuated Tube

Evacuated tube collectors (Figure 3.14) can be designed to increase water/steam temperatures to as high as 350 °F (177 °C). They may use a variety of configurations, but they generally encase both the absorber surface and the tubes of heat transfer fluid in a vacuum sealed tubular glass for highly efficient insulation. Evacuated tube collectors are the most efficient collector type for cold climates with low level diffuse sunlight.

There are three types of evacuated tube collectors: (1) direct flow, (2) heat pipe, and (3) Sydney tube type. The direct flow type has the heat transfer fluid flowing through copper tubes attached to a absorber plate mounted inside the evacuated tube. The heat pipe type uses a heat pipe attached to the absorber plate. The heat pipe transfers the heating energy to the condensing section of the heat pipe where the collector fluid is warmed. This occurs in the header where the evacuated tubes are connected. The last type has an evacuated tube called a Sydney tube (Figure 3.15) that encapsulates a heat conductor sheet (absorber) with heat transfer fluid carrying tubes. The Sydney tube slides over the absorber section and locks into the collectors header forming a tight seal. Within the Sydney tube the space between inner and outer glass tube is evacuated. The selective coating is sputtered onto the outside of the inner glass tube. A heat conductor/transfer sheet is located inside the inner glass tube that conducts the heat from the glass into the U-form tubes carrying the heat transfer fluid. The Sydney tube type collector’s performance can be enhanced through the use of a compound parabolic concentrator located behind each tube. This device will reflect the solar radiation that passes between each evacuated tube back to the underside of the cylindrical absorber in the collector tubes. There are various other construction methods like flat or round absorber, and single- or double-walled glass.

All evacuated tube collectors have the following in common:

- A collector consists of several evacuated glass tubes positioned in parallel and are joined by an insulated manifold at one end for the supply and removal of the heat transfer fluid (Figure 16).

- Due to the vacuum insulation (pressure < 10-2 Pa) heat loss caused by conduction and convection are minimal.

- The upper end of the tubes is connected to the “header.”

- The tubes are circular to withstand the outside pressure.

3.3.2.3.1 Design considerations

Evacuated tube collectors have only insulated tubes and a pipe header to which the evacuated are connected. The collector fluid tubes use copper and typically black chrome is used as the selective absorber coating. The pipe header is insulated and has a protective cover.

3.3.2.3.2 Applications

This type of collector is used when there is a need for hotter water than would be necessary for domestic hot water heating. Hotter water is needed for applications that have cooling in the summer as a requirement and in some cases where building heating is a major need. Solar assisted cooling uses an absorption or adsorption chiller, which requires hot water temperatures in the range of 130 to 350 °F (55 to 180 °C).

An evacuated tube type collector may also be chosen as an alternative for a flat plate collector in areas where winter time freezing occurs. In this case, water would be used as the heat transfer fluid in the collector and warm water would be pumped into the outside piping and collector when freezing of those components is threatened. This would required a small amount of heated water due to the insulating quality of the evacuated tubes. As a result, the cost and inferior heat transfer characteristics of a water glycol mixture is avoided. Also the a hotter water could be produced in the collector providing a lower heat transfer fluid flow thereby reducing distribution pipe and storage tank sizes. Also, the heat exchanger between the collector and the storage tank could be avoided thus reducing the required leaving collector temperature. As a total system, the evacuated tube collector could have a total cost competitive with a flat plate collector system. The use of evacuated tube type collectors obviates most of the stagnation concerns associated with an anti-freeze heat transfer fluid.

3.3.2.4 Concentrating Collectors

These collectors use curved mirrors to focus sunlight onto a receiver tube (sometimes encased in an evacuated tube called CPC or compound parabolic collectors) running through the middle or focal point of the trough (Figure 3.17). They can heat their heat transfer fluid to temperatures as high as 570 °F (299 °C). Such high temperatures are needed for industrial uses and for making steam in electrical power generation. Because they use only direct-beam sunlight, parabolic-trough systems require tracking systems to keep them focused toward the sun and are best suited to areas with high direct solar radiation like the desert areas of the Southwest United States. These collector systems require large areas for installation, so they are usually ground mounted. They are also particularly susceptible to transmitting structural stress from wind loading and being ground mounted helps with the structural requirements.

Parabolic-trough collectors generally require greater maintenance and supervision and particularly benefit from economies of scale, so are generally used for larger systems. Because of their higher cost and greater maintenance needs this type of collector is not recommended for US Army heating needs in their standard buildings.

Colorado.

3.3.3 Hot air collectors

Air collectors currently do not have a large market share (e.g., 0.5% in Germany in 2009). Nevertheless they can be considered as an alternative in certain situations (e.g., space heating, when an air heating system is used). As the type name indicates air collectors use air as the heat transfer medium (instead of water and glycol). This has some advantages:

- Air does not freeze or evaporate and air does not degrade when exposed to high temperatures. Freezing and stagnation thus does damage the system. Air collectors are usually intrinsically safe.

- Fresh air may be used directly as heat transfer fluid; a volume of air has no cost and is non- toxic. Leakage in the system does not cause damage to the system nor the

On the other hand some disadvantages are:

- Air has lower heat transfer attributes and a lower heat capacity (a factor of 4 times lower compared to water and glycol).

- Higher driving power by a fan is needed for a comparable mass flow [kg/h] to a fluid glycol.

- Larger cross sections for conduction pipes are necessary.

- If water is to be heated, an additional heat exchanger is needed.

3.3.4 Solar hot water collector efficiency

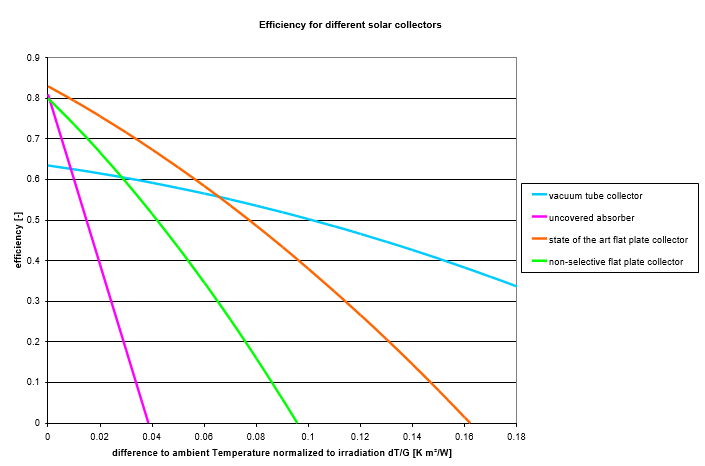

The efficiency of the solar collector is directly related to heat losses from the surface of the collector. Heat losses are predominantly governed by the thermal gradient between the temperature of the collector surface and the ambient temperature. Efficiency decreases when either the ambient temperature falls or when the collector temperature increases. This decrease in efficiency can be mitigated by increasing the insulation of the unit by sealing the unit in glass (for flat collectors), or providing a vacuum seal (for evacuated tube collectors). Figure 3.18 shows efficiency curves of these collectors. When comparing collector efficiencies, it is important to assume the same type of area (net vs. gross), and the same irradiation level.

The thermal performance of solar hot water collectors is characterized by:

- The power curve as shown in Figure 3.18, parameters: η0, a1 and a2.

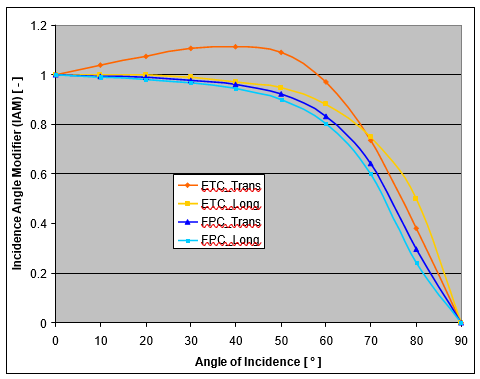

- Incidence Angle Modifier (IAM) because of the optical efficiency of the collector.

- Thermal capacity (Ceff), which is the measure of thermal response to heating and cooling.

- The quantity of heat input into the collector to heat it by -457.87 °F (1 °K). This information would be available from the collector manufacturer. This value is used in the solar collector simulation computer programs as it relates to the small time steps in the program to the estimated heat removed. The larger the Ceff, the more energy that will be lost when switching off and on the solar heat transfer pump, which can happen as the weather changes during the day.

3.3.4.1 Power curve

For the power curve, collector performance is measured at different operating temperatures and with perpendicular insolation of G > 29,360 Btu/hr/sq ft (800 W/m2). The collector’s performance is represented by:

Figure 3.19 shows the power curves of four low* temperature collectors. A “rule of thumb” is to select a collector type that achieves an efficiency h ~ 50% for the working temperature range.

For use in water and low temperature space heating, both flat plate collectors (with solar glass and selective coating) and evacuated tube collectors are applicable. Both have certain advantages in specific applications especially when freezing, leaving water temperature, available space and installation cost are concerns. For applications with large collector fields, these two collector types should always be considered, and the final decision to select one technology over the other should be based on annual simulation results.

3.3.4.2 Incidence angle modifier

The IAM [-] describes the modification of the conversion factor h0 of the collector for non- perpendicular solar incidence angles. By definition, an IAM equal to 1 is for normal incidence. The IAM has a significant effect on the performance of stationary installed collectors as the incidence angle changes throughout the day and the year. Incidence angles less than 50 degrees do not have a significant effect on the solar thermal collector efficiency while an Incidence angle of 90 degrees is equal to a total reflection of the sun rays. Figure 3.20 shows the IAM curves of a typical FPA and a typical ETC.

The longitudinal IAM (i.e., in the direction parallel to the tubes for the ETCs) of the ETCs is similar to the flat plate collector’s while the transversal IAM of most ETCs shows a characteristic increase at intermediate angles.

Collectors with a flat absorber surface, which includes some types of evacuated tubes, only have 100% efficiency at midday. Other evacuated tube collectors collect solar radiation in a perpendicular fashion over a longer period of the day since the collecting absorber surface is cylindrical. This feature can be enhanced by placing an optimally designed reflective compound parabolic concentrator (CPC) mirror behind the collectors, causing the sunlight to strike the collector at a perpendicular angle for a great percentage of the day. This provides most of the advantages of tracking systems while avoiding their high costs. The advantages of the CPC ETC include:

- longer usable daylight time.

- more continuous power in the course of the day.

- high target temperatures over the entire day.

- higher daily and yearly energy yields.

3.3.4.3 Thermal capacity

The thermal capacity ( Ceff ) of the collector has an effect on the system performance. Every time the collector heats up, energy is absorbed by the collector. This energy is not fully recovered as useful energy. In simulations, this factor is taken into account when calculating the annual energy yield. The thermal capacity ( Ceff ) of the collector is expressed in kWh per m2 collector area per degree K. The influence of this parameter is comparably small. Nevertheless, the lower the thermal capacity of the collector, the better.

3.4 Heat transfer fluid

As the solar collector heats up, the fluid in the collector increases in temperature. This fluid is then moved out of the collector so the heat can be extracted for some useful purpose. Larger solar systems either use the heat immediately, or use heat stored in a tank of heated fluid. When the solar system is located in a freezing climate, the fluid flowing through the collector is often an anti- freeze solution. When storing heated fluid in a tank, water is often the preferred medium (to reduce cost). If this is the case, a second fluids is used and flow through a heat exchanger is required to transfer the heat from the collector to the storage tank. There also may be a third fluid, potable water, which is used directly for domestic purposes, in which case another heat exchanger would be required. The heat transfer fluids used in a solar hot water system are very important and must meet a number of requirements to ensure good performance:

- a high heat capacity and conductivity allowing efficient heat transportation from the collector.

- anti-corrosive-protection, if mixed or corrosion prone materials are present in the collector.

- non-toxicity and environmental-friendliness.

- low viscosity for easy pumping of the fluid.

- low cost and availability.

Except where freezing is a concern, water is the fluid of choice in solar energy hot water systems. It has a low cost, is plentiful, and is compatible with the materials used in these systems. Water also has high heat capacity, good conductivity, a low viscosity, and can withstand the hot temperatures that are experienced during stagnation periods of time. Passive solar systems normally use water in the solar collector. Water is also often used in evacuated tube collectors. In freezing climates an anti-freeze liquid must be used in flat plate collectors.

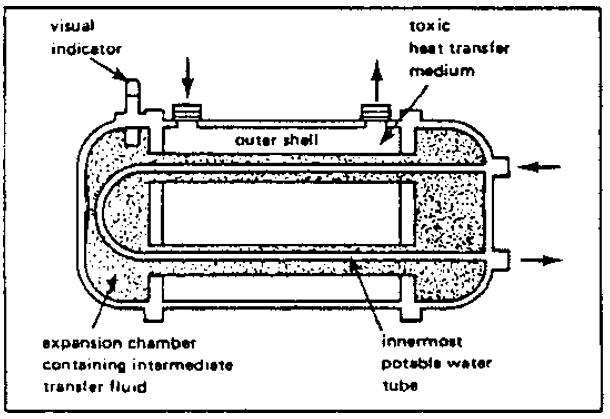

Water used for domestic hot water is a potable water source that must be kept safe to drink and not be contaminated by chemicals. Because of this, large systems must have at least two fluid circulating systems, one that flows through the solar collector, and another that is heated and dispensed as domestic hot water. A heat exchanger is placed between the two piping systems for the movement of captured heat from the collector heat transfer fluid to the domestic water. Figure 3.6 shows such a system. Separating the collector fluid from the domestic water allows for water treatment to prevent corrosion of the piping and collector materials. To protect the potable water a double wall heat exchanger must be used when the heated fluid is not-potable. This separation also allows for an anti-freeze solution to be used in the solar collectors if needed.

3.4.1 Anti-freeze fluids

The typical anti-freeze solution is a mixture of water and propylene glycol, but a water/ethylene glycol solution, silicon oil, hydrocarbon oil, or refrigerant could also be used. With the water/propylene glycol fluid the percent glycol should be 40% or less. A 40% solution begins to freeze at –11 °F; below that temperature, an ice slurry develops that does not readily freeze solid causing pipes to burst. A glycol solution greater than 50% is not recommended due to a higher viscosity and lower heat capacity. Systems using glycol should be aware that it has a greater tendency to seep through piping joints than water and thus the piping system should be sealed with care and checked for leaks at scheduled intervals. Glycol is not compatible with zinc so galvanized pipes should not be used.

The use of automatic water makeup to heat transfer fluids selected to be an anti-freeze should be avoided. This is because the water makeup will dilute the anti-freeze mixture and making the fluid more likely to freeze when exposed to cold outdoor temperatures. The anti-freeze fluid should be periodically checked to assure proper performance.

3.4.2 S tagnation

The heat transfer fluid used in the collector must also withstand the high stagnation temperatures. Stagnation occurs when the heat transfer fluid stays in the collector too long and a high temperature is reached greater than the normal due to the heat from solar radiation. This could happen when there is a pump or control failure, when the heating demand of the users and the storage tank are satisfied or when the system is down for maintenance. Under normal operation the heat transfer fluid is under a pressure to avoid vaporization. Most collector systems are designed to operate at pressures below 125 psig (833 kPa). This is to allow the use of standard piping components (class

125) and avoid using more costly components. Since the solar collector is generally placed at a higher elevation than other parts of the system the static head of the fluid column must be added to the operating pressure in the collector when determining the pressure on components. This means pressures at or just below 75 psig (500kPa) are common in the solar collector. At this pressure, a 60/40 mixture of water/glycol will begin to vaporize at 320 °F (160 °C). If the pressure is dropped to 45 psig (310 kPa), then vaporization would begin at a temperature of 284 °F (140 °C). Vaporization of water at these pressures is 307 °F and 275 °F (153 and 135 °C), respectively.

When vaporization begins to occur, the resulting gas displaces the liquid in the collector and to some degree in the nearby piping. This displaced fluid should be directed to a recapturing tank so that it can be used again to fill the system when the temperature cools down. There are safety valves in the piping system that must be certified for the highest temperature that may occur. They should be placed on connections to the lines leading to the recapture tanks.

The disadvantages of frequent vaporizations are:

- Water/glycol mixtures will have a shorten life when exposed to at temperatures in the 300 °F – 320 °F (149 – 160 °C) range.

- Anti-corrosion additives and contaminants may stick to the interior of pipes and absorbers flow channels.

- Operating personnel need to spend time refilling the system.

All glycol systems should use the Pressure Stagnation Protection (PSP) method. This method allows over sizing of the pressure relief valve to 150 psi (1034 kPa), which allows the system pressure to rise with stagnation temperature. This protects the fluid from overheating and preserves the properties of the glycol by keeping it in a liquid form at all times.

Since glycols begin to break down and start to become corrosive when heated to temperatures greater than 240 °F (116 °C). One way to avoid this condition is to send excess heat to a nearby low priority heat user such as a swimming pool when the temperature in the storage tank is satisfied. Such a connection to a swimming pool is established using another heat exchanger with redundant, multiple pumps. Another solution may be to route external fluid to air heat exchangers, or in some cases, to a ventilated recooling device. For smaller applications (up to several hundred m2) it is sufficient to design the solar loop expansion vessel in a way that both the additional volume of the heat transfer medium (due to the decreasing density), and the volume of the evaporated heat transfer medium (in case of stagnation) can be absorbed.

3.5 Piping arrangements

3.5.1 Collector piping alternatives

It is advised to choose collectors that feature a good emptying behavior during stagnation. This will reduce the strain on the heat transfer fluid and reduce the steam production of the collector field.

During periods of stagnation, it is likely that steam will develop in the collectors. The steam will push the fluid out of the collectors. The fluid will later be sent back into the collector field when the collector field is cooled down again.

Tables 3.1 to 3.9 list a selection of collector designs. The pipe manifolds are shown in relation to the arrangement of the tubes attached to the collector absorbers. Both flat plate and evacuated tube collectors are addressed. An attempt is made to assess the different absorber piping designs with respect to:

- steam producing power (SPP) (a low SSP is a positive property with respect to a smaller expansion vessel needed).

- glycol strain (a low glycol strain is a positive property).

- air vent possibility (a good air vent behavior is a positive property).

For the designs listed in Tables 3.1 to 3.9, real measurements of the SPP were carried out on sample collectors. For the other designs, estimations are provided that are deduced from the experience made in the investigations. In these tables, note that:

- A question mark “?” in the tables means that even no rough estimation on the expected behavior can be given. The assessment is very rough and the given collection of piping designs is not complete.

- ETC = Evacuated tube collector.

- FPC = Flat plate collector.

There are two methods connecting a row of collectors together – with an external manifold or an internal manifold. The external manifold uses a supply and return header and all the collectors in the row have supply connections to the supply header and also have a flow outlet connected to the return header. The internal manifold type connection has the supply pipes of each collector connected to the next collector. The same applies to the return side of the collector piping. The piping of the collector is similar to that listed in Table 3.9. Internal manifolds offer the following advantages:

- less piping reducing costs and heat loss

- more attractive

Disadvantages of internal manifolds are that they:

- make it more difficult to achieve a drainable system

- make it difficult to balance collector flow for a long row of collectors

- make it hard to remove a single collector

- create more significant expansion and contraction issues for a long

3.5.2 Solar System piping arrangements

Large solar systems serving multi-buildings typically have several heat transfer loops. First, there is one with the fluid flowing through the solar collector (solar primary loop). This one may contain an anti-freeze solution. Second, there is one that circulates from the heat exchanger with the collector fluid to the thermal storage tank (solar secondary loop). Third, may be a circulating fluid that heat the domestic hot water. Finally, there may be a circulating system going to a district or building heating system. Normally circulating systems use water as their heat transfer fluid. The types of piping systems can be characterized as:

- Solar supported local heating system with a two-pipe network:

- two-Pipe Networks with Decentralized Domestic Hot Water Storages

- two-Pipe Networks with Decentralized Heat Transfer Units

- Solar supported local heating system with a four-pipe network:

- four-pipe networks with centralized energy storage and centralized domestic hot water storage

- four-pipe networks with centralized energy storage and decentralized domestic hot water storage

- Solar supported district heating network with direct interconnection of a centralized solar thermal system:

- solar thermal plant directly feeding the supply line of an existing district heating network

- solar thermal plant directly preheating the return line of an existing district heating

3.5.2.1 Two pipe networks

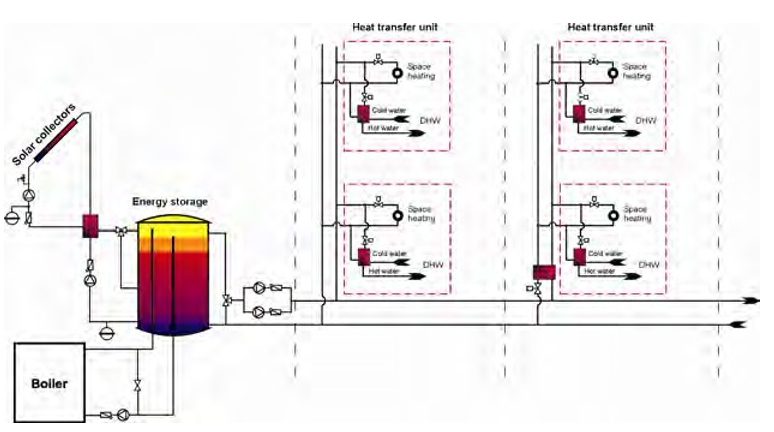

In two-pipe networks, the heat supply to the heat sinks (buildings), including both domestic hot water and space heating, is by means of a pair of pipes. Domestic hot water is heated in a decentralized manner for the individual consumers using continuous flow water heaters, or by means of decentralized DHW storages using the charge-store principle. The two-pipe network shown in Figure 3.21 consists of centralized energy storage and decentralized heat transfer units for each building or unit connected to the network.

The energy storage is the central point for all heat flows and acts as a hydraulic gateway. To guarantee a reliable supply of heat with this design, it is essential that adequate reserves are permanently stored in the upper region of the energy storage (stand-by volume) so as to cover peak demand.

Domestic hot water is heated in a decentralized manner using continuous flow water heaters (usually via plate heat exchangers – no additional storage needed).

Two-pipe networks in combination with decentralized heat transfer units are ideally suited for use in compact unit blocks (medium to high energy densities). For less energy dense clusters of buildings (lower heating requirements per length of heat distribution pipe), a two-pipe network in combination with decentralized daily storages is preferable (Figure 3.22).

Solar-supported heating networks in combination with decentralized heat transfer units are also highly suitable for use in existing buildings. This includes buildings that are equipped with central space heating, but that also have a decentralized supply of domestic hot water (off-peak energy storage units). Whenever these energy storage units have to be renewed, they could then be replaced by decentralized heat transfer units. At the same time, improvements to the heat insulation (insulation of the building envelope, new windows) will mean that the space heating system can operate at lower temperatures.

Figure 3.23 shows a modified two-pipe network with decentralized energy storage for each building connected and additional decentralized solar thermal systems. The single consumers within the building are supplied via decentralized heat transfer units.

This concept is recommended for local heating grids with high energy densities (high heating requirements of buildings per length of heat distribution pipe), especially for new-built facilities that are constructed in several construction stages (modular enlargement).

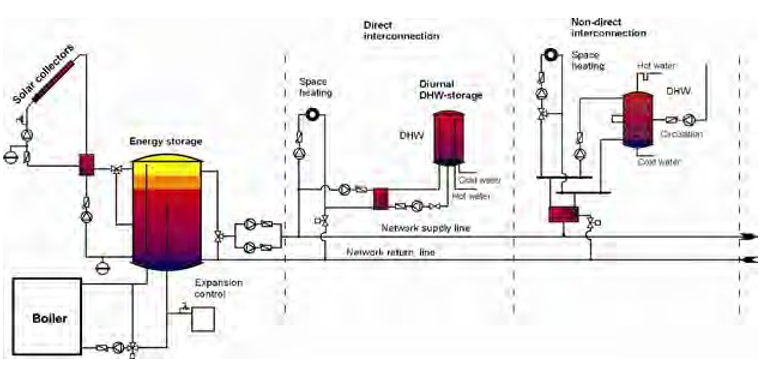

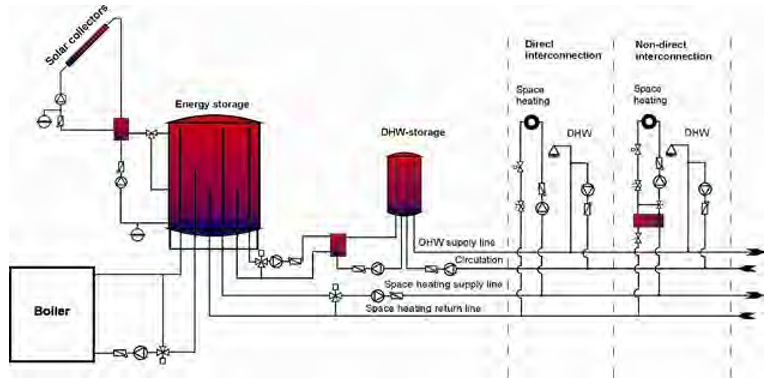

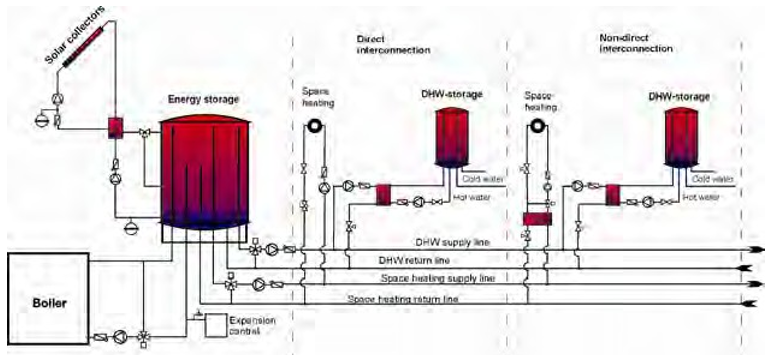

3.5.2.2 Four-pipe networks with centralized energy storage and centralized domestic hot water storage

In four-pipe networks, the heat is distributed through four pipes. In addition to flow and return lines for the space heating system, four-pipe networks also have two pipes for the supply of domestic hot water (distribution pipe for domestic hot water and circulation line).

The four-pipe network shown in Figure 3.24 consists of centralized energy storage and centralized domestic hot water storage. The energy storage is the central point for all heat flows and acts as a hydraulic gateway. Domestic hot water is heated in a centralized manner using the charge-store principle.

Due to the high distribution losses in the DHW supply and circulation lines, this concept is especially recommended for local heating grids with high energy densities (high heating requirements per length of heat distribution pipe) such as Army New-Recruit Troop Training Sites.

The four-pipe network shown in (Figure 3.25) consists of centralized energy storage and decentralized domestic hot water storages in the buildings.

The energy supply for space heating and domestic hot water is performed by two pairs of distribution pipes using the heating water as the heat transfer medium within the whole heating network.

Due to its higher specific investment costs, this concept is especially recommended for local heating grids with high energy densities (high heating requirements per length of heat distribution pipe) such as Army New-Recruit Troop Training Sites.

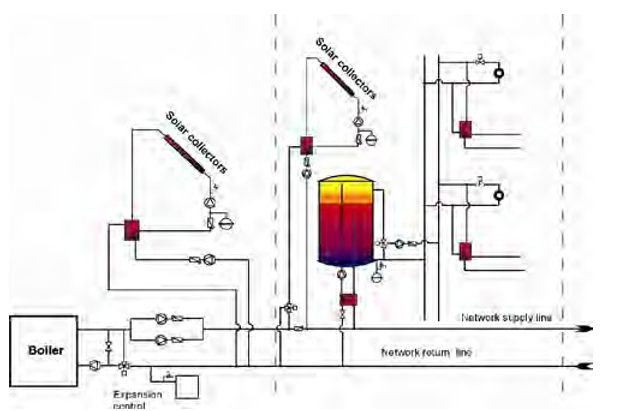

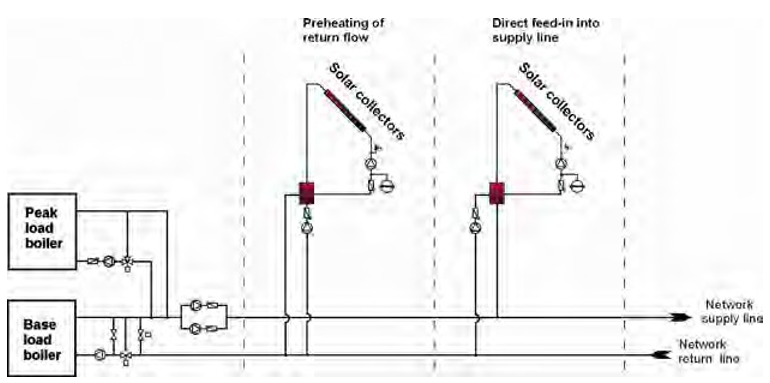

The direct interconnection of a solar thermal system to an existing district heating network (Figure 3.26) is applied to provide some base load energy directly to the grid. In general, two different applications are most commonly used:

- solar thermal system directly preheating the return line of an existing district heating network

- solar thermal system directly feeding the supply line of an existing district heating

Applications of this kind are commonly designed based on the available space and the existing dimensions of the district heating branch on site, and not on the actual load in a specific building. The solar collectors can either be roof- or ground-mounted. The majority of these systems can be operated without additional storage as they use the district heating network as storage (as long as they provide a small amount of heat in comparison to the total load in the district heating system).

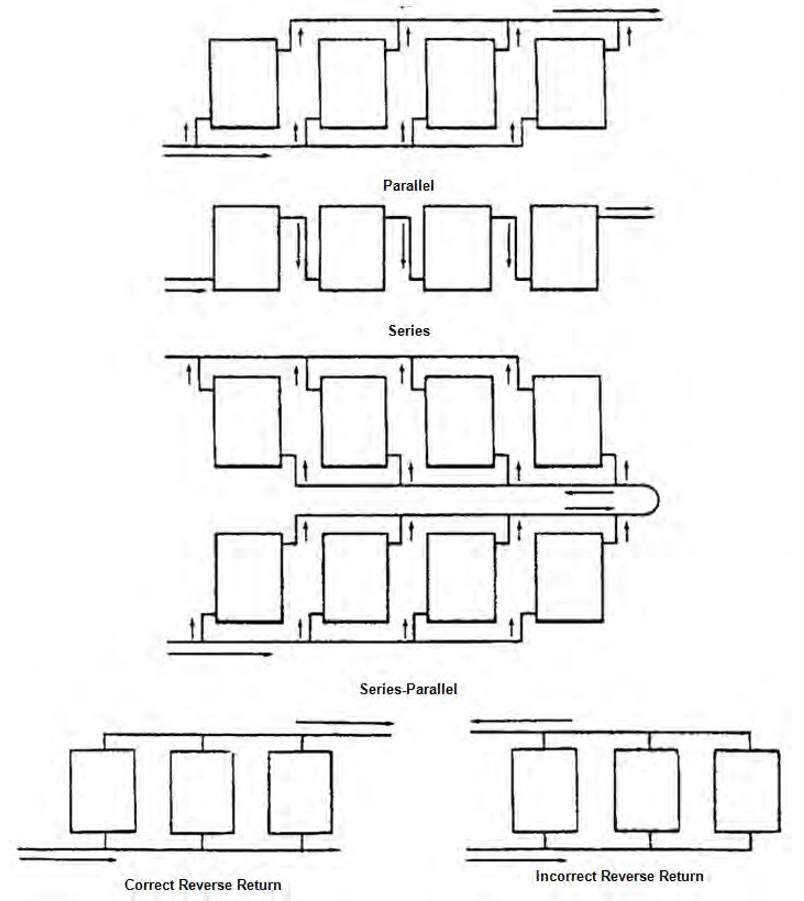

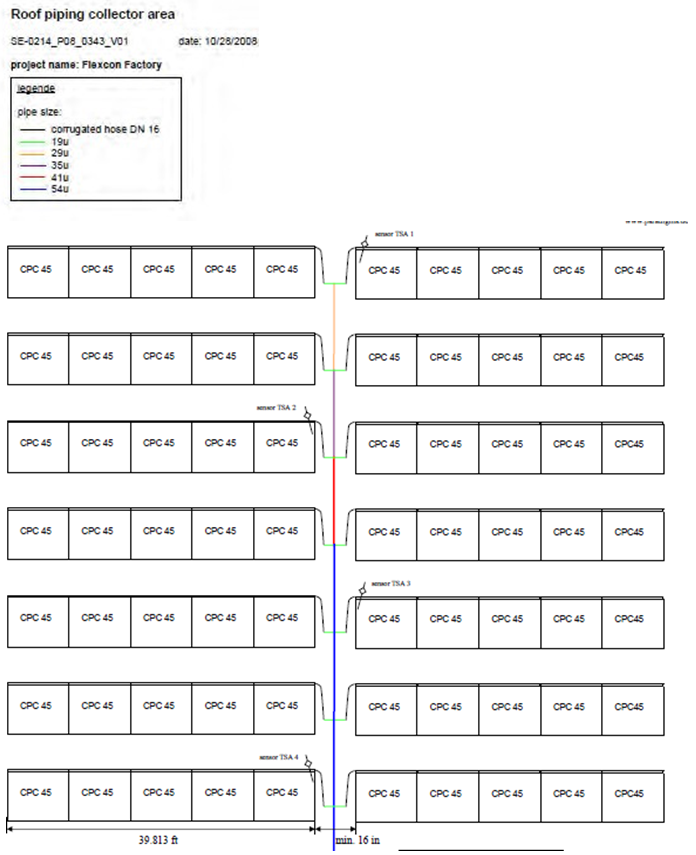

3.5.3 Balancing fluid flow in collector field

A large solar hot water system will flow through many solar collectors. The flow through each solar collector should have basically the same pressure drop. This will ensure that the system is balanced such that each collector is receiving the same flow rate of heat transfer fluid. Thus the fluid temperature increase of each collector will be equal to the others. With several collectors, a reversed return piping system is used to achieve the equal pressure drop. This assumes each collector is arranged to have parallel fluid flow. In some systems, the collectors are arranged for flow in series. Here the fluid goes from one collector to the next collector picking up heat along the way. Figure 3.27 shows the parallel and series flow arrangements. There is a limit to the number of collectors that can be arranged in series due to the pressure drop of the flow through so many collectors.

In large collector systems a combination of parallel and series flow is used. An arrangement of collectors that have series flow are placed in a group or zone. Each group is then arranged to have parallel flow with the other collector groups. Figure 3.27 shows such arrangement. The collector layout could also have a group collectors with parallel flow placed in series with another collector group having parallel flow.

The design objective is for the pressure drop of each group to be equal. This is accomplished using a reverse return piping layout (Figure 3.27). The amount of piping should be kept at a minimum to keep installation costs low and to minimize the system resistance to flow, which helps keep the required pump pressures at acceptable levels. A rule of thumb is for the pressure drop per pipe length in the collector to be slightly more than three times the pressure drop per pipe length in the general piping system.

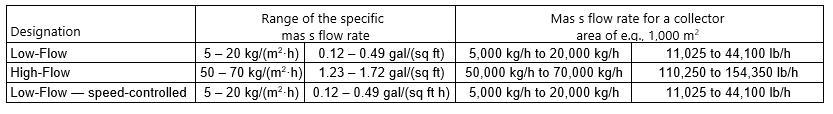

With these large solar thermal systems it is advised to design the collector loop system as a low flow system. That means that the flow rate is ~0.37 gal/sq ft*h (15 l/m2). By contrast, in the so called high flow type the flow rate is in the range of 1.23–1.72 gal/sq ft*hr (50–70 l/m2*hr). This type system is well suited for small (less than 161sq ft [15 m2]) solar DHW systems and for applications having a small temperature rise such as solar cooling applications. It is possible with a low flow system to connect more collectors that are piped for series flow. The flow through an individual collector is then less compared to a high flow operation mode and a higher temperature rise is possible. The benefits of a low flow system are its:

- lower investment costs due to smaller pipe sizes required

- lower piping lengths, as more collectors are connected in series (lower investment) and reduced heat losses

- smaller pump requirements (lower investment), which use less pump energy (lower operation costs) due to lower volume flow

- requirement for less fluid in the solar loop, and consequently less glycol (lower investment)

- quicker response to achieving the target temperature in heat storage tanks including those using stratified charging

- ability to achieve a useful temperature in a single flow cycle a greater percentage of the

Table 3.10 lists the range of specific mass flow rates of the various operating modes of the solar installations and the differences in the total mass flow rate in the feed and return piping of an assumed collector area of 10,760 sq ft (1000 m2). This example shows that larger manifold pipe sizes and higher electric pump power are required when the high-flow operating mode is used in large-scale solar thermal systems. The costs of installing and operating this type of system would therefore soon exceed acceptable limits.

3.5.4 Freeze protection

When water freezes, it expands. Frozen water in pipes is likely to rupture them. This is a major cause of breakdown of solar heating systems. Water thus must be prevented from freezing inside the collector loop. The following options will protect against freezing of the piping system:

- Provide drain-back pipe design.

- Use an antifreeze solution in the outdoor collector and piping, a water-glycol

- Add heat from the storage tank to the outside piping and collector

Each solution has its benefits and drawbacks. Some general aspects are discussed here. The freeze protection implemented is usually not a free choice, but depends on the selected collector technology and supplier; it is usually based on environmental conditions, operating temperature, maintenance, costs, and local availability.

In a drain-back system design the water drains from the collector when the collector pump is stopped. This requires that the collector is constructed and the piping is installed so that no water remains in any part that could freeze. A continuous downward gradient for all the draining pipes is needed to avoid locations where pipes sag and where water can be trapped; this can be difficult to achieve. After a system draindown, the system pump is started to fill the pipes and solar collector with water. This means that the pump must be able to push the circulating fluid up the piping system when starting. The extra amount of pump pressure needed is equal to the height difference between the top of the collector and the position of the drain-back storage vessel. The drain-back approach can also be used during stagnation periods, preventing the formation of steam, and avoiding the resulting expansion and high pressures within the collector. Refer to Section 3.5 for various collector piping arrangements.

Please note: Common practice of solar system designers in Europe is to use a water glycol mixture in drain back systems nevertheless. This way it is ensured that heat transfer fluid does not freeze if draining does not work perfectly. The remaining advantage of drainback systems is: Overheating of oversized collector fields does not necessarily lead to problems during stagnation.

When using a water-glycol mixture the freezing temperature of the mixture is lowered (lower than water alone). The mixing ratio determines the lowest operating temperature. It is important to follow the manufacturer’s or installation engineer’s recommendations. The different types of glycol that could be used vary in their properties. See Section 3.4.1 (p 33) for more information. The pipes still need to be pitched to drains so that the collector field can be emptied for maintenance even when a anti-freeze collector fluid is used.

The main drawbacks of using a glycol antifreeze water mixture are that:

- The heat capacity of the fluid is reduced while the viscosity is increased. This causes a reduction in efficiency of the collector field. In addition, for a comparable mass flow more pump energy is

- Glycol deteriorates when heated up to common collector stagnation temperatures that occur in evacuated tube collectors. Deteriorated glycol forms solid particles that can block and even destroy the collector loop. The glycol mixture then must be

- Care must be taken when an antifreeze solution is used to heat domestic water (which is a potable water source). The two fluids must be kept separate with a leak detection device at the point of heat exchange. This affects the efficiency of the heat

The third option is to use water in a closed, always filled loop, and to heat up the collector loop by turning on the pump when near freezing temperatures are sensed. This means that heat from the storage tank is used to prevent the collector and piping from freezing. This has the obvious drawback of wasting captured heat and using pump power. Therefore, the viability strongly depends on the site with the specific occurring ambient temperatures in winter. It would probably be the logical choice at locations where freezing temperatures are not normally experienced. This option also requires a reliable power supply because if no power is available, this option will fail to protect the collector loop.

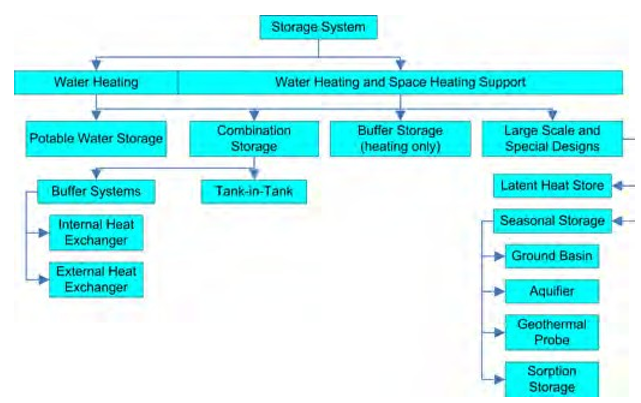

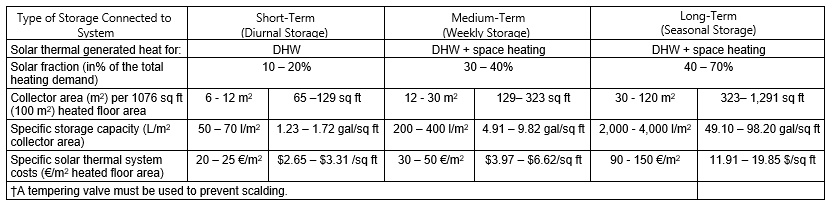

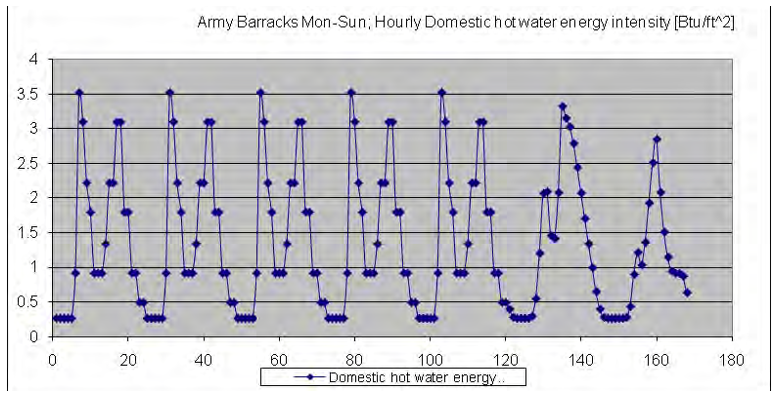

3.5.5 Air elimination