Use search to quickly locate question answers – open up a search box (ctrl+f), then enter a keyword from the question to navigate you to those terms in the course material

Introduction

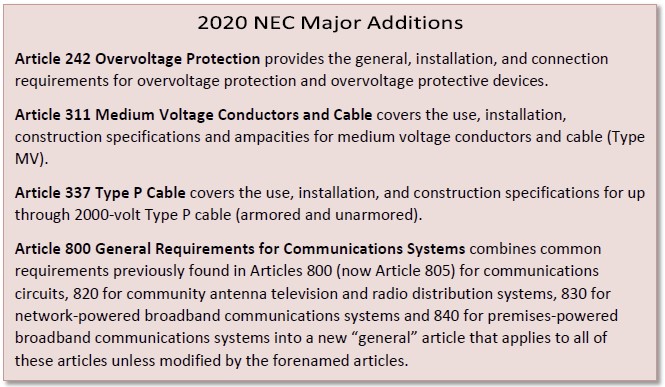

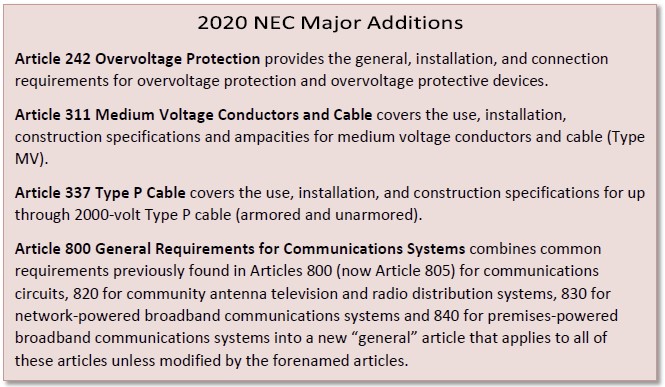

Every three years, the National Electrical Code® (NEC®) is revised and expanded. Initially the NFPA® received 3,730 public suggestions for changes, which resulted in 1,400 first revisions. There were 1,930 public comments submitted in response to these 1,400 first revisions, resulting in 635 second revisions. Changes included editorial clarification, expanded requirements, new requirements, deleted requirements, and the relocation of other requirements. Nine new articles were proposed, and four new articles were added to the 2020 NEC. With the fast pace of technology, it’s more important than ever for anyone participating in the electrical industry to get up to speed with all the changes.

Every three years, the National Electrical Code® (NEC®) is revised and expanded. Initially the NFPA® received 3,730 public suggestions for changes, which resulted in 1,400 first revisions. There were 1,930 public comments submitted in response to these 1,400 first revisions, resulting in 635 second revisions. Changes included editorial clarification, expanded requirements, new requirements, deleted requirements, and the relocation of other requirements. Nine new articles were proposed, and four new articles were added to the 2020 NEC. With the fast pace of technology, it’s more important than ever for anyone participating in the electrical industry to get up to speed with all the changes.

What to Expect

In this course the student will be presented an overview of the most significant changes found in the 2020 NEC. This is part 1 of a series of courses covering the changes and will progress through each chapter and its articles presenting the many important changes. The changes will be underlined for easy recognition and a short synopsis of the reason for the change is presented as well.

Note: Underlines are New Text, Strikethrough are Deleted Text

Article 500 – Hazardous (Classified) Locations, Classes I, II, and III, Division 1 and 2

500.7(K) Combustible Gas Detection System as a Protection TechniqueReason for Change: The requirements for a combustible gas detection system as a protection technique was sufficiently revised and expanded to provide more specific detail for the installation and operation of a gas detection system.

500.7 Protections Techniques.

500.7 Protections Techniques.Section 500.7(A) through (L) shall be acceptable protection techniques for Electrical and electronic equipment in hazardous (classified) locations shall be protected by one or more of the techniques in 500.7(A) through (P).

(K) Combustible Gas Detection System. A combustible gas detection system shall be permitted as a means of protection in industrial establishments with restricted public access and where the conditions of maintenance and supervision ensure that only qualified persons service the installation. Where such a system is installed, equipment specified in 7(K)(1), (K)(2), or (K)(3) shall be permitted.

(1) General Any gas detection system utilized as a protection technique shall meet all of the requirements in 500.7(K)(1)(a) through (K)(1)(e).

(a) The gas detection equipment used shall be listed for Class I, Division 1 and listed for the detection of the specific gas or vapor to be encountered.

(b) The gas detection system shall not utilize portable or transportable equipment or temporary wiring methods.

(c) The gas detection system shall only use pointtype sensors. The system shall be permitted to be augmented with open-path (line-of-sight)–type sensors, but open- path–type sensors shall not be the basis for this protection technique.

(d) The type of detection equipment, its listing, installation location(s), alarm and shutdown criteria, and calibration frequency shall be documented where combustible gas detectors are used as a protection technique.

(e) The applications for the use of combustible gas detection systems as a protection technique shall be limited to 7(K)(2), or (K)(3), or (K)(4).

[see NEC for (4) Informational Notes here]

(1)(2) Inadequate Ventilation.

(2)(3) Interior of a Building or Enclosed Space.

(3)(4) Interior of a Control Panel.

(see NEC for complete Code text)

Reason for Change: Four new protection techniques were added protection of electrical and electronic equipment in hazardous (classified) locations.

500.7 Protections Techniques.

500.7 Protections Techniques.Section 500.7(A) through (L) shall be acceptable protection techniques for Electrical and electronic equipment in hazardous (classified) locations shall be protected by one or more of the techniques in 500.7(A) through (P).

(L) Inherently Safe Optical Radiation “op ” This protection technique shall be permitted for equipment in Class I or II, Division 1 or 2 locations for which the equipment is identified.

Informational Note: The identified class and division depends on the intended explosive atmosphere and the number of faults applied as part of the protection technique evaluation.

(M) Protected Optical Radiation “op pr.” This protection technique shall be permitted for equipment in Class I or II, Division 2 locations for which the equipment is identified.

Informational Note: The identified class and division depends on the intended explosive atmosphere as part of the protection technique evaluation.

(N) Optical System With Interlock “op sh.” This protection technique shall be permitted for equipment in Class I or II, Division 1 or 2 locations for which the equipment is identified.

Informational Note: The identified class and division depends on the intended explosive atmosphere and the number of faults applied as part of the protection technique evaluation.

(O) Protection by Skin Effect Trace Heating “IEEE 844.1.” This protection technique shall be permitted for skin effect trace heating equipment in Class I, Division 2; Class II, Division 2; or Class III, Division 2 for which it is listed.

(see NEC for complete Code text)

Article 501 – Class I Locations

501.10(A)(1) Type TC-ER-HL cable and Type P CableReason for Change: Type TC-ER-HL cable and Type P cable were added as two new wiring methods for Class I, Division 1 locations.

501.10 Wiring Methods. (Class I Locations)

501.10 Wiring Methods. (Class I Locations) Wiring methods shall comply with 501.10(A) or (B).

(A) Class I, Division 1.

(1) General. In Class I, Division 1 locations, the following wiring methods in (a) through (f) shall be permitted:

(a) Threaded rigid metal conduit (Type RMC) or threaded steel intermediate metal conduit (Type IMC). (see NEC for complete details)

(b) Type MI cable (see NEC for complete details)

(c) Type MC-HL cable (see NEC for complete details)

(d) Type ITC-HL cable (see NEC for complete details)

(e) Optical fiber cable Types OFNP, OFCP, OFNR, OFCR, OFNG, OFCG, OFN, and OFC (see NEC for complete details)

(f) In industrial establishments with restricted public access, where the conditions of maintenance and supervision ensure that only qualified persons service the installation, for applications limited to 600 volts nominal or less, and where the cable is not subject to physical damage, and terminated with fittings listed for the location, Type TC-ER-HL cable. Type TC-ER-HL cable shall be listed for use in Class I, Division 1 or Zone 1 locations and shall be installed in accordance with 336.10.

Informational Note: See the information on construction, testing, and marking of cables and cable fittings in ANSI/UL 2225-2013, Cables and Cable- Fittings for Use in Hazardous (Classified) Locations.

(g) In industrial establishments with restricted public access, where the conditions of maintenance and supervision ensure that only qualified persons service the installation, listed Type P cable with metal braid armor, with an overall jacket, terminated with fittings listed for the location, and installed in accordance 337.10.

Informational Note No. 1: For information on construction, testing, and marking of Type P cable, see ANSI/UL 1309-2017, Marine Shipboard Cable.

Informational Note No. 2: For information on construction, testing, and marking of cable fittings, see ANSI/UL 2225-2013, Cables and Cable-Fittings for Use in Hazardous (Classified) Locations.

Article 505 – Zone 0, 1, and 2 Locations

Table 505.9(C)(2)(4) Equipment SuitabilityReason for Change: Table 505.9(C)(2)(4) was replaced with an updated applicability table and is now Table 505.9(C)(2)(4) Equipment Suitability.

505.9 Equipment. (Zone 0, 1, and 2 Locations).

505.9 Equipment. (Zone 0, 1, and 2 Locations).(C) Marking. Equipment shall be marked in accordance with 505.9(C)(1) or (C)(2).

(2) Zone Equipment. Equipment meeting one or more of the protection techniques described in 505.8 shall be marked with all of the following in the order shown:

(1) Class I (equipment shall be permitted to omit the Class I marking)

(2) Zone [in accordance with Table 9(C)(2)(4)]

(3) Symbol “AEx”

(4) Protection technique(s) in accordance with Table 9(C)(2)(4)

(5) Applicable material group in accordance with Table 505.9(C)(1)(2) or a specific gas or vapor.

(6) Temperature classification in accordance with 9(D)(1)

(7) Equipment protection level (EPL)

Table 505.9(C)(2)(4) Types of Protection Designation Equipment Suitability

(see NEC for complete Code text and table)

Article 511 – Commercial Garages, Repair, and Storage

511.12 GFCI Requirements for Commercial GaragesReason for Change: Revision to 511.12 now points and aligns GFCI requirements for commercial garages to GFCI requirements of 210.8(B).

511.12 Ground-Fault Circuit-Interrupter Protection for Personnel. (Commercial Garages, Repair and Storage).

511.12 Ground-Fault Circuit-Interrupter Protection for Personnel. (Commercial Garages, Repair and Storage).All 125-volt, single-phase, 15- and 20-ampere receptacles installed in areas where electrical diagnostic equipment, electrical hand tools, or portable lighting equipment are to be used shall have Ground-fault circuit-interrupter protection for personnel shall be provided as required in 210.8(B).

Article 513 – Aircraft Hangars

513.3(D) “Adequately Ventilated” in Aircraft HangarReason for Change: Revision clarifies what “adequately ventilated” means for an adjacent area of an aircraft hangar by replacing “adequately ventilated” with “mechanically ventilated at a rate of four or more air changes per hour.”

513.3 Classification of Locations. (Aircraft Hangers).

513.3 Classification of Locations. (Aircraft Hangers).(D) Areas Suitably Cut Off and Ventilated. Adjacent areas in which flammable liquids or vapors are not likely to be released, such as stock rooms, electrical control rooms, and other similar locations, shall be unclassified where adequately ventilated and mechanically ventilated at a rate of four or more air changes per hour, or designed with positive air pressure, or where effectively cut off from the hangar itself by walls or partitions..

Article 514 – Motor Fuel Dispensing Facilities

514.11(A) Motor Fuel Dispensing FacilitiesReason for Change: The grounded conductor should be disconnected simultaneously with the all the other conductors when the emergency disconnect is activated. Revisions also make it clear that the equipment grounding conductors should not be disconnected by the emergency disconnect.

514.11 Circuit Disconnects. (Motor Fuel Dispensing Facilities).

514.11 Circuit Disconnects. (Motor Fuel Dispensing Facilities).(A) Emergency Electrical Disconnects. Fuel dispensing systems shall be provided with one or more clearly identified emergency shutoff devices or electrical disconnects. Such devices or disconnects shall be installed in approved locations but not less than 6 m (20 ft) or more than 30 m (100 ft) from the fuel dispensing devices that they serve. Emergency shutoff devices or electrical disconnects shall disconnect power to all dispensing devices; to all remote pumps serving the dispensing devices; to all associated power, control, and signal circuits; and to all other electrical equipment in the hazardous (classified) locations surrounding the fuel dispensing devices. When more than one emergency shutoff device or electrical disconnect is provided, all devices shall be interconnected. Resetting from an emergency shutoff condition shall require manual intervention and the manner of resetting shall be approved by the authority having jurisdiction. [30A:6.7]

The emergency shutoff device shall disconnect simultaneously from the source of supply, all conductors of the circuits, including the grounded conductor, if any. Equipment grounding conductors shall remain connected.

Exception: Intrinsically safe electrical equipment need not meet this requirement. [30A:6.7].

Article 517 – Health Care Facilities

517.10(B) Areas Used Exclusively for Intramuscular Injections (Immunizations)Reason for Change: New areas not covered by the wiring and protection methods of Part II of Article 517 [Intramuscular injections (immunizations), etc.] have been added to 517.10(B).

517.10 Applicability. (Health Care Facilities) (B) Not Covered.

517.10 Applicability. (Health Care Facilities) (B) Not Covered.Part II shall not apply to the following:

(1) Business offices, corridors, waiting rooms, and the like in clinics, medical and dental offices, and outpatient facilities

(2) Areas of nursing homes and limited care facilities wired in accordance with Chapters 1 through 4 of this Code where these areas are used exclusively as patient sleeping rooms

(3) Areas used exclusively for any of the following purposes:

(a) Intramuscular injections (immunizations)

(b) Psychiatry and psychotherapy

(c) Alternative medicine

(d) Optometry

Informational Note: See NFPA 101-2015 2018, Life Safety Code®.

Reason for Change: Further revision to 517.16 provides better explanation of use of isolated receptacles outside the patent care vicinity. Where installed, an isolated ground receptacle cannot eliminate the two equipment grounding paths required by 517.13.

517.16 Use of Isolated Ground Receptacles. (Health Care Facilities).

517.16 Use of Isolated Ground Receptacles. (Health Care Facilities).An isolated ground receptacle, if used, shall not defeat the purposes of the safety features of the grounding systems detailed in 517.13. [99:6.3.2.2.5(A)]

(A) Inside of a Patient Care An isolated grounding ground receptacle shall not be installed within a patient care vicinity. [99:6.3.2.2.7.1(B)] [99:6.3.2.2.5(B)]

(B) Outside of a Patient Care Vicinity. Isolated ground receptacle(s) installed in patient care spaces outside of a patient care vicinity(s) shall comply with 517.16(B)(1) and (B)(2).

(1) The equipment grounding terminals of isolated ground receptacles installed in branch circuits for patient care spaces shall be connected to an insulated equipment grounding conductor in accordance with 250.146(D) in addition to the equipment grounding conductor path required installed in a wiring method described in 13(A).

The equipment grounding conductor connected to the equipment grounding terminals of isolated ground receptacles in patient care spaces shall be clearly identified along the equipment grounding conductor’s entire length by green insulation with one or more yellow stripes.

(2) The insulated equipment grounding conductor required in 517.13(B)(1) shall be clearly identified along its entire length by green insulation, with no yellow stripes, and shall not be connected to the grounding terminals of isolated equipment ground receptacles but shall be connected to the box or enclosure indicated in 517.13(B)(1)(2) and to non–current-carrying conductive surfaces of fixed electrical equipment indicated in 517.13(B)(1)(3).

Informational Note No. 1: This type of installation is typically used where a reduction of electrical noise (electromagnetic interference) is necessary, and parallel grounding paths are to be avoided.

Informational Note No. 2: Care should be taken in specifying a system containing isolated ground receptacles, because the grounding impedance is controlled only by the grounding wires of the effective ground-fault current path is dependent upon the equipment grounding conductor(s) and does not benefit from any conduit or building structure in parallel with the equipment grounding path conductor. [99:A.6.3.2.2.7.1].

Reason for Change: Revisions were made to provide clarity by requiring a qualified person (written record) to perform a test process of GFP primary current injection.

517.17 Ground-Fault Protection of Equipment. (Health Care Facilities).

517.17 Ground-Fault Protection of Equipment. (Health Care Facilities).(A) Applicability (see NEC for complete text)

(B) Feeders (see NEC for complete text)

(C) Selectivity (see NEC for complete text)

(D) Testing. When equipment ground-fault protection of equipment is first installed, each level shall be performance tested to ensure compliance with 517.17(C). This testing shall be conducted by a qualified person(s) using a test process in accordance with the instruction provided with the equipment. A written record of this testing shall be made and shall be available to the authority having jurisdiction.

Reason for Change: New text was added to give needed guidance to what parts of Article 700 that Article 517 amends.

517.26 Application of Other Articles. (Health Care Facilities).

517.26 Application of Other Articles. (Health Care Facilities).The life safety branch of the essential electrical system shall meet the requirements of Article 700, except as amended by Article 517.

(1) Section 700.4 shall not apply.

(2) Section 700.10(D) shall not apply.

(3) Section 700.17 shall be replaced with the following: Branch circuits that supply emergency lighting shall be installed to provide service from a source complying with 700.12 when normal supply for lighting is interrupted or where single circuits supply luminaires containing secondary batteries.

(4) Section 700.32 shall not apply.

Informational Note No. 1: For additional information, see NFPA 110-2013 2019, Standard for Emergency and Standby Power Systems.

Informational Note No. 2: For additional information, see 517.29 and NFPA 99-2015 2018, Health Care Facilities Code.

Reason for Change: Battery systems are now permitted to serve as the alternate source for all or part of an essential electrical system.

517.30 Sources of Power. (Health Care Facilities).

517.30 Sources of Power. (Health Care Facilities).(A) Two Independent Power Sources. Essential electrical systems shall have a minimum of the following two independent sources of power: a normal source generally supplying the entire electrical system and one or more alternate source(s) sources for use when the normal source is [99:6.4.1.1.4] [99: 6.7.1.2.2]

(B) Types of Power Sources.

(1) Generating Units. Where the normal source consists of generating units on the premises, the alternate source shall be either another generating set or an external utility [99:6.4.1.1.5] [99:6.7.1.2.3]

(2) Fuel Cell Systems. (see NEC for complete text).

(3) Battery Systems. Battery systems shall be permitted to serve as the alternate source for all or part of an essential electrical system.

Informational Note: For information on installation of battery systems, see NFPA 111-2016, Standard on Stored Electrical Energy Emergency and Standby Power Systems.

Reason for Change: Identification and marking requirements for the life safety branch and critical branch of essential electrical systems was added to 517.31(C)(1)(a) Raceways and cables required to be field- or factory-marked as a component of the essential electrical system at intervals not to exceed 7.6 m (25 ft).

517.31 Requirements for Essential Electrical System. (Health Care Facility).

517.31 Requirements for Essential Electrical System. (Health Care Facility).(A) Separate Branches (see NEC of complete text)

(B) Transfer Switches (see NEC of complete text)

(C) Wiring Requirements

(1) Separation from Other Circuits. The life safety branch and critical branch of the essential electrical system shall be kept entirely independent of all other wiring and equipment and shall not enter the same raceways, boxes, or cabinets with each other or other wiring. [99:6.7.5.2.1]

(a) Raceways, cables, or enclosures of the life safety and critical branch shall be readily identified as a component of the essential electrical system (EES). Boxes and enclosures (including transfer switches, generators, and power panels) shall be field- or factory-marked and identified as a component of the EES. Raceways and cables shall be field- or factory-marked as a component of the EES at intervals not to exceed 6 m (25 ft).

(b) Conductors of the life safety branch or critical branch shall not enter the same raceways, boxes, or cabinets with each other or any other wiring system. It shall be permitted for the branch conductors to occupy common equipment, raceways, boxes, or cabinets of other circuits not part of the life safety branch and critical branch where such wiring complies with one of the following:

(1) Is in transfer equipment enclosures

(2) Is in exit or emergency luminaires supplied from two sources

(3) Is in a common junction box attached to exit or emergency luminaires supplied from two sources

(4) Is for two or more circuits supplied from the same branch and same transfer switch

(c) The wiring of the equipment branch shall be permitted to occupy the same raceways, boxes, or cabinets of other circuits that are not part of the essential electrical

(d) Where Category 2 (general care) locations are served from two separate transfer switches on the essential electrical system in accordance with 517.18(A), Exception 3, the Category 2 (general care) circuits from the two separate systems shall be kept independent of each other.

(e) Where Category 1 (critical care) locations are served from two separate transfer switches on the essential electrical system in accordance with 517.19(A), Exception No. 2, the critical care circuits from the two separate systems shall be kept independent of each other.

Article 518 – Assembly Occupancies

518.6 Illumination of Working SpaceReason for Change: A new section was added to require outdoor fixed service equipment at assembly occupancies to be provided with proper illumination.

518.6 Illumination. (Assembly Occupancies).

518.6 Illumination. (Assembly Occupancies).Illumination shall be provided for all working spaces about fixed service equipment, switchboards, switchgear, panelboards, or motor control centers installed outdoors that serve assembly occupancies. Control by automatic means only shall not be permitted. Additional lighting outlets shall not be required where the workspace is illuminated by an adjacent light source.

Article 520 – Theaters, Audience Areas of Motion Picture and Television Studios, Performance Areas, and Similar Locations

520.25(B) Dimmers for Theatrical UseReason for Change: Resistance- and reactor-type dimmers for theatrical use have been deleted as a recognized dimmer option.

520.25 Dimmers. (Theaters, Audience Areas of Motion Picture and Television Studios, Performance Areas, and Similar Locations).

520.25 Dimmers. (Theaters, Audience Areas of Motion Picture and Television Studios, Performance Areas, and Similar Locations).Dimmers shall comply with 520.25(A) through (D).

(A) Disconnection and Overcurrent (see NEC for complete text)

(B) Resistance- or Reactor-Type Dimmers. Resistance- or series reactor-type dimmers shall be permitted to be placed in either the grounded or the ungrounded conductor of the circuit. Where designed to open either the supply circuit to the dimmer or the circuit controlled by it, the dimmer shall then comply with 404.2(B). Resistance- or reactor-type dimmers placed in the grounded neutral conductor of the circuit shall not open the

(C) (B) Autotransformer-Type (see NEC for complete text)

(D) (C) Solid-State-Type Dimmers. (see NEC for complete text).

Reason for Change: Listed hard usage cords or cables (rather than extra-hard usage cords or cables) permitted for use with portable stage equipment in protected applications.

520.68 Conductors for Portables. (Theaters, Audience Areas of Motion Picture and Television Studios, Performance Areas, and Similar Locations).

520.68 Conductors for Portables. (Theaters, Audience Areas of Motion Picture and Television Studios, Performance Areas, and Similar Locations).

(A) Conductor Type.

(1) General Flexible conductors, including cable extensions, used to supply portable stage equipment shall be listed extra-hard usage cords or cables.

(2) Protected Applications. Listed, hard usage (junior hard service) cord or cable shall be permitted where all of the following conditions are met:

(1) The cord or cable is protected from physical damage by attachment over its entire length to a pipe, tower, truss, scaffold, or other substantial support structure, or installed in a location that inherently prevents physical damage to the cord.

(2) The cord or cable is connected to a branch circuit protected by an overcurrent protective device rated at not over 20 amperes.

(3) The cord or cable does not exceed 30 m (100 ft) in length.

(2) (3) Stand Lamps

(3) (4) Luminaire Supply Cords

(4) (5) High-Temperature Applications

(5) (6) Breakouts

(See NEC for complete text).

Article 525 – Carnivals, Circuses, Fairs, and Similar Events

525.20(G) Wiring Methods for Carnivals, Circuses, Fairs, and Similar EventsReason for Change: Non-conductive matting for flexible cords or cables accessible at carnivals, etc. must be secured in place to the walkway surface to minimize tripping hazard. This section now allows either secured matting or an approved alternate protection method.

525.20 Wiring Methods. (Carnivals, Circuses, Fairs, and Similar Events).

525.20 Wiring Methods. (Carnivals, Circuses, Fairs, and Similar Events).(G) Protection. Flexible cords or cables accessible to the public shall be arranged to minimize the tripping hazard and shall be permitted to be covered with nonconductive matting secured to the walkway surface or protected with another approved cable protection method, provided that the matting or other protection method does not constitute a greater tripping hazard than the uncovered cables. It Burying cables shall be permitted to bury cables. The requirements of 300.5 shall not apply.

Article 545 – Manufactured Buildings and Relocatable Structures

Article 545, Part II Manufactured Buildings and Relocatable StructuresReason for Change: A new Part II was added to Article 545 for “Relocatable Structures” with a definition of same added at 545.2.

Article 545 Manufactured Buildings and Relocatable Structures.

Article 545 Manufactured Buildings and Relocatable Structures.Part II. Relocatable Structures

545.20 Application Provisions. Relocatable structures shall comply with Part II of this article and the applicable sections of Part I.

545.22 Power Supply.

(A) Feeder.

(B) Number of Supplies.

(C) Identification.

(D) Grounding

545.24 Disconnecting Means and Branch-Circuit Overcurrent Protection. (A) Disconnection Means.

(B) Branch-Circuit Protective Equipment and Panelboards.

545.26 Bonding of Exposed Non-Current-Carrying Metal Parts.

545.27 Intersystem Bonding.

545.28 Ground-Fault Circuit-Interrupters (GFCI).

(See NEC for complete Code text).

Article 547 – Agricultural Buildings

547.5(G) GFCI Protection in Agricultural BuildingsReason for Change: Revision eliminates GFCI protection for receptacles rated above 125-volt, single-phase, 20-ampere (240-volt and 3-phase receptacles) at agricultural buildings.

547.5 Wiring Methods. (Agricultural Buildings).

547.5 Wiring Methods. (Agricultural Buildings).(G) Receptacles. All 125-volt, single-phase, 15- and 20-ampere receptacles installed in the locations listed in (1) through (4) shall have Ground-fault circuit-interrupter protection shall be provided as required in 210.8(B). GFCI protection shall not be required for other than 125-volt, 15- and 20-ampere receptacles installed within the following areas:

(1) Areas having an equipotential plane

(2) Outdoors

(3) Damp or wet locations

(4) Dirt confinement areas for livestock.

Reason for Change: Revision provides clarity that a distribution point is required for livestock agricultural buildings and structures. Branch circuits and feeders to agricultural buildings are required to be supplied through a distribution point and overcurrent protection is required for all underground feeder and branch circuit installations.

547.9 Electrical Supply to Building(s) or Structure( s) from a Distribution Point. (Agricultural Buildings).

547.9 Electrical Supply to Building(s) or Structure( s) from a Distribution Point. (Agricultural Buildings).A distribution point shall be permitted to supply Any agricultural building or structure for livestock located on the same premises shall be supplied from a distribution point. More than one distribution point on the same premises shall be permitted. The overhead electrical supply shall comply with 547.9(A) and (B), or with 547.9(C). The underground electrical supply shall comply with 547.9(C).

Any existing agricultural building or structure for other than livestock and any existing buildings and structures not under the scope of Article 547 shall be permitted to be supplied in accordance with 250.32(B)(1) Exception No. 1.

(A) Site-Isolating (See NEC for complete Code text)

(B) Service Disconnecting Means and Overcurrent Protection at the Building(s) or Structure( s). (See NEC for complete Code text)

(C) Service Disconnecting Means and Overcurrent Protection at the Distribution Where The service disconnecting means and overcurrent protection for each set of feeders or branch circuits are shall be located at the distribution point, the. The service disconnecting means shall be installed in accordance with Part VI of Article 230. The feeders or branch circuits supplied to buildings or structures shall comply with the provisions of 250.32 and Article 225, Parts I and II.

Informational Note: Methods to reduce neutralto- earth voltages in livestock facilities include supplying buildings or structures with 4-wire single- phase services, sizing 3-wire single-phase service and feeder conductors to limit voltage drop to 2 percent, and connecting loads line-to-line.

(D) Identification. Where a site is supplied by more than one distribution point, a permanent plaque or directory shall be installed at each of these distribution points denoting the location of each of the other distribution points and the buildings or structures served by each..

Article 550 – Mobile Homes, Manufactured Homes, and Mobile Home Parks

550.13(B) GFCI Protection at Mobile and Manufactured HomesReason for Change: Language was revised to include 210.8(A), which will provide GFCI protection to those additional locations at a dwelling covered in 210.8(A) for a mobile or manufactured home such as a detached garage. Revision also eliminates GFCI protection for receptacles rated above 125-volt, single- phase, 20-ampere (240- volt and 3-phase receptacles).

550.13 Receptacle Outlets. (Mobile and Manufactured Homes)

550.13 Receptacle Outlets. (Mobile and Manufactured Homes)(B) Ground-Fault Circuit-Interrupters (GFCI). All 125-volt, single-phase, 15- and 20- ampere receptacle outlets installed in the locations specified in 550.13(B)(1) through (5) shall have GFCI protection for personnel. Ground-fault circuit-interrupter protection shall be provided as required in 210.8(A). GFCI protection shall not be required for other than 125-volt, 15- and 20-ampere receptacles installed within a mobile or manufactured home in the following areas:

(1) Outdoors, including Compartments accessible from outside the unit

(2) Bathrooms, including receptacles in luminaires

(3) Kitchens, where receptacles are installed to serve countertop surfaces

(4) Sinks, where receptacles are installed within 1.8 m (6 ft) of the outer edge of the sink

(5) Dishwashers

Informational Note: For information on protection of dishwashers, see 422.5.

Reason for Change: Revisions clarify that a receptacle providing power to a mobile or manufactured home in accordance with 550.10 need not be provided with GFCI protection.

550.32 Service Equipment. (Mobile or Manufactured Homes)

550.32 Service Equipment. (Mobile or Manufactured Homes)(E) Additional Receptacles. Additional receptacles shall be permitted for connection of electrical equipment located outside the mobile home, and all such 125-volt, single-phase, 15- and 20-ampere receptacles shall be protected by a listed groundfault circuit-interrupter. Receptacles located outside a mobile or manufactured home shall be provided with ground-fault circuit-interrupter protection as specified by 210.8(A). Where receptacles provide power to a mobile or manufactured home in accordance with 550.10, ground-fault circuit- interrupter protection shall not be required.

Reason for Change: New requirements added to require a reverse polarity indicating device that provides a continuous visible or audible signal to be installed in an RV in accordance with the installation instructions.

551.40 120-Volt or 120/240-Volt, Nominal, Systems. (Recreational Vehicles).

551.40 120-Volt or 120/240-Volt, Nominal, Systems. (Recreational Vehicles).(A) General (see NEC for complete Code text)

(B) Materials and (see NEC for complete Code text)

(C) Ground-Fault Circuit-Interrupter (see NEC for complete Code text)

(D) Reverse Polarity Device. A reverse polarity indicating device that provides a continuous visible or audible signal shall be installed in the recreational vehicle in accordance with the installation instructions and shall respond to the reversal of the ungrounded and the grounded conductors in the 120-volt ac system..

Reason for Change: Revision eliminates GFCI protection for receptacles rated above 125-volt, single-phase, 20-ampere (30- and 50-ampere receptacles for RV site equipment).

551.71 Type Receptacles Provided. (Recreational Vehicle Parks).

551.71 Type Receptacles Provided. (Recreational Vehicle Parks).(F) GFCI Protection

(1) All 125-volt, single-phase, 15- and 20-ampere receptacles shall have listed ground- fault circuit-interrupter protection for personnel. The GFCI devices used in RV site electrical equipment shall not be required to be weather or tamper resistant in accordance with 9 and 406.12.

Informational Note: The percentage of 50 ampere sites required by 551.71 could be inadequate for seasonal recreational vehicle sites serving a higher percentage of recreational vehicles with 50 ampere electrical systems. In that type of recreational vehicle park, the percentage of 50 ampere sites could approach 100 percent.

(2) Thirty- and 50-ampere receptacles used in recreational vehicle site equipment shall not be required to meet the requirements of 210.8(B)..

Article 555 – Marinas, Boatyards, Floating Buildings, and Commercial and Non-commercial Docking Facilities

555.2 New Definitions for Marinas, Boatyards, Floating Buildings, and Commercial and Noncommercial Docking FacilitiesReason for Change: New definitions were added to Article 555 for clarity as these terms were previously not defined. Several new definitions were extracted from NFPA 303-2016 (Fire Protection Standard for Marinas and Boatyards).

555.2 Definitions. (Marinas. Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).

555.2 Definitions. (Marinas. Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).The definitions in this section shall apply only within this article.

Berth.

Boatyard.

Bulkhead.

Crane.

Docking

Facility.

Electrical Datum Plane. (Previous definition at 555.2 moved to 682.2) (New definition for Electrical Datum Plane added to Article 100 and assigned to CMP-7)

Floating Building.

Marina.

Marine Marina Power Outlet. An enclosed assembly that can include equipment such as receptacles, circuit breakers, fused switches, fuses, a watt-hour meter(s), panelboards, and monitoring means approved identified for marine marina use. [303:3.3.13]

Monorail.

Mooring(s).

Shore Power.

Slip.

Storage,

Dry Stack.

Wharf.

(See NEC for complete definitions and Code text)..

Reason for Change: All metal parts in contact with the water, all metal piping, and all non- current-carrying metal parts that are likely to become energized are required to be connected to the grounding bus in the panelboard.

555.13 Bonding of Non-Current-Carrying Metal Parts. (Marinas. Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).

555.13 Bonding of Non-Current-Carrying Metal Parts. (Marinas. Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).All metal parts in contact with the water, all metal piping, and all non-current-carrying metal parts that are likely to become energized shall be connected to the grounding bus in the panelboard using solid copper conductors; insulated, covered, or bare; not smaller than 8 AWG. Connections to bonded parts shall be made in accordance with 250.8. (This was 553.11 in the 2017 NEC.).

Reason for Change: Ground-Fault Protection of Equipment (GFPE) and Ground- Fault Circuit- Interrupter (GFCI) Protection: GFP protection divided into three parts:

555.35 Ground-Fault Protection of Equipment (GFPE) and Ground-Fault Circuit- Interrupter (GFCI) Protection. (Marinas, Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).

555.35 Ground-Fault Protection of Equipment (GFPE) and Ground-Fault Circuit- Interrupter (GFCI) Protection. (Marinas, Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).(A) Ground-Fault Protection. For other than floating buildings, ground-fault protection for docking facilities shall be provided in accordance with 555.35(A)(1) through (A)(3).

(1) Receptacles Providing Shore Receptacles installed in accordance with 555.33(A) shall have individual GFPE set to open at currents not exceeding 30 milliamperes.

(2) GFCI Protection for All 125-volt, single-phase, 15- and 20-ampere receptacles for other than shore power shall be protected in accordance with 555.33(B)(1) and (B)(2).

(3) Feeder and Branch-Circuit Conductors with GFPE. Feeder and branch-circuit conductors that are installed on docking facilities shall be provided with GFPE set to open at currents not exceeding 100 milliamperes. Coordination with downstream GFPE shall be permitted at the feeder overcurrent protective device.

Exception to (3): Transformer secondary conductors of a separately derived system that do not exceed 3 m (10 ft) and are installed in a raceway shall be permitted to be installed without ground-fault protection. This exception shall also apply to the supply terminals of the equipment supplied by the transformer secondary conductors.

(B) Leakage Current Measurement Device. Where more than three receptacles supply shore power to boats, a leakage current measurement device shall be available and be used to determine leakage current from each boat that will utilize shore power.

Informational Note No. 1: Leakage current measurement will provide the capability to determine when an individual boat has defective wiring or other problems contributing to hazardous voltage and current. The use of a test device will allow the facility operator to identify a boat that is creating problems. In some cases a single boat may cause an upstream GFPE device protecting a feeder to operate even though multiple boats are supplied from the same feeder. The use of a test device will help the facility operator prevent a particular boat from contributing to hazardous voltage and current in the marina area.

Informational Note No. 2: An annual test of each boat with the leakage current measurement device is a prudent step toward determining if a boat has defective wiring that may be contributing hazardous voltage and current. Where the leakage current measurement device reveals that a boat is contributing hazardous voltage and current, repairs should be made to the boat before it is permitted to utilize shore power.

Reason for Change: The previous Article 553 (Floating Buildings) was incorporated into new Part III of Article 555.

Article 555 Part III. Floating Buildings (Marinas, Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).

Article 555 Part III. Floating Buildings (Marinas, Boatyards, Floating Buildings, and Commercial and Noncommercial Docking Facilities).555.50 Service Conductors.

555.21 Feeder Conductors.

555.52 Installation of Services and Feeders

(A) Flexibility

(B) Wiring Methods

555.53 Ground-Fault Protection.

555.54 Grounding.

(A) Grounding of Electrical and Nonelectrical

(B) Installation and Connection of Equipment Grounding

(C) Identification of Equipment Grounding

(D) Grounding Electrode Conductor

555.55 Insulated

555.56 Equipment

(A) Electrical

(B) Cord-Connected Appliances..

Article 590 – Temporary Installations

590.4(G), Ex. No. 2 Temporary InstallationsReason for Change: On construction sites, a new exception to 590.4(G) permits branch-circuits that are permanently installed in framed walls and ceilings to be used for temporary power or lighting (with GFCI protection).

590.4 General (Temporary Installations).

590.4 General (Temporary Installations).(G) A box, conduit body, or other enclosure, with a cover installed, shall be required for all splices except where:.

Exception No. 1: On construction sites, a box, conduit body, or other enclosure shall not be required for either of the following conditions:

(1) The circuit conductors being spliced are all from nonmetallic multiconductor cord or cable assemblies, provided that the equipment grounding continuity is maintained with or without the box.

(2) The circuit conductors being spliced are all from metal-sheathed cable assemblies terminated in listed fittings that mechanically secure the cable sheath to maintain effective electrical continuity.

Exception No. 2: On construction sites, where permanent wiring in framed walls and ceilings is GFCI protected and used to supply temporary power or lighting:.

(1) A cover shall not be required for splices installed completely inside of junction boxeswith plaster rings.

(2) Listed pigtail-type lampholders shall be permitted to be installed in ceiling-mountedjunction boxes with plaster rings.

(3) Finger safe devices for supplying and connection to devices shall also be permitted.

Reason for Change: A new section was added to provide guidance for the AHJ in the reuse of overcurrent protective devices in temporary installations and the use of current limiting overcurrent protective devices required for solidly grounded wye electrical services of more than 150 volts to ground but not exceeding 1000 volts phase-to-phase in temporary installations.

590.8 Overcurrent Protective Devices. (Temporary Installations).

590.8 Overcurrent Protective Devices. (Temporary Installations).(A) Where Reused. Where overcurrent protective devices that have been previously used are installed in a temporary installation, these overcurrent protective devices shall be examined to ensure these devices have been properly installed, properly maintained, and there is no evidence of impending failure.

(B) Service Overcurrent Protective Devices. Overcurrent protective devices for solidly grounded wye electrical services of more than 150 volts to ground but not exceeding 1000 volts phase-tophase shall be current limiting.

Informational Note: The phrase “evidence of impending failure” means that there is evidence such as arcing, overheating, loose or bound equipment parts, visible damage, or deterioration. The phrase “properly maintained” means that the equipment has been maintained in accordance with the manufacturers’ recommendations and applicable industry codes and standards. References for manufacturers’ recommendations and applicable industry codes and standards include but are not limited to NEMA AB 4-2017, Guidelines for Inspection and Preventative Maintenance of Molded- Case Circuit Breakers Used in Commercial and Industrial Applications; NFPA 70B-2019, Recommended Practice for Electrical Equipment Maintenance; NEMA GD 1-2016, Evaluating Water-Damaged Electrical Equipment; and IEEE 1458-2017, IEEE Recommended Practice for the Selection, Field Testing, and Life Expectancy of Molded-Case Circuit Breakers for Industrial Applications.

Every three years, the National Electrical Code® (NEC®) is revised and expanded. Initially the NFPA® received 3,730 public suggestions for changes, which resulted in 1,400 first revisions. There were 1,930 public comments submitted in response to these 1,400 first revisions, resulting in 635 second revisions. Changes included editorial clarification, expanded requirements, new requirements, deleted requirements, and the relocation of other requirements. Nine new articles were proposed, and four new articles were added to the 2020 NEC. With the fast pace of technology, it’s more important than ever for anyone participating in the electrical industry to get up to speed with all the changes.

Every three years, the National Electrical Code® (NEC®) is revised and expanded. Initially the NFPA® received 3,730 public suggestions for changes, which resulted in 1,400 first revisions. There were 1,930 public comments submitted in response to these 1,400 first revisions, resulting in 635 second revisions. Changes included editorial clarification, expanded requirements, new requirements, deleted requirements, and the relocation of other requirements. Nine new articles were proposed, and four new articles were added to the 2020 NEC. With the fast pace of technology, it’s more important than ever for anyone participating in the electrical industry to get up to speed with all the changes.

500.7 Protections Techniques.

500.7 Protections Techniques.