Steam System Basics

Why Steam?

There are three principal forms of energy used in industrial processes: electricity, direct-fired heat, and steam. Electricity is used in many different ways, including mechanical drive, heating, and electrochemical reactions. Direct-fired energy directly transfers the heat of fuel combustion to a process. Steam provides process heating, pressure control, mechanical drive, and component separation, and is a source of water for many process reactions.

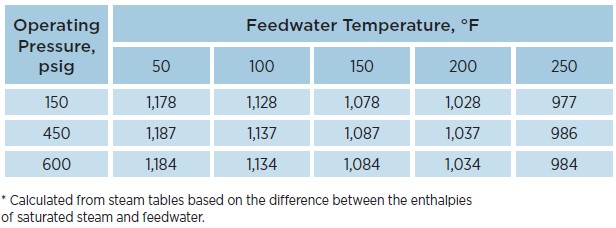

Steam has many performance advantages that make it an indispensable means of delivering energy. These advantages include low toxicity, ease of transportability, high efficiency, high heat capacity, and low cost with respect to the other alternatives. Steam holds a significant amount of energy on a unit mass basis (between 1,000 and 1,250 British thermal units per pound [Btu/lb]) that can be extracted as mechanical work through a turbine or as heat for process use. Since most of the heat content of steam is stored as latent heat, large quantities of heat can be transferred efficiently at a constant temperature, which is a useful attribute in many process heating applications.

Steam is also used in many direct contact applications. For example, steam is used as a source of hydrogen in steam methane reforming, which is an important process for many chemical and petroleum refining applications. Steam is also used to control the pressures and temperatures of many chemical processes. Other significant applications of steam are to strip contaminants from a process fluid, to facilitate the fractionation of hydrocarbon components, and to dry all types of paper products.

The many advantages that are available from steam are reflected in the significant amount of energy that industry uses to generate it. For example, in 2006, U.S. manufacturers used about 4,762 trillion Btu of steam energy, which represents about 40% of the total energy used in industrial process applications for product output.

Steam used by energy intensive industries is especially significant. For example, in 2006 the forest products industry used approximately 2,117 trillion Btu of energy to generate steam, accounting for about 76% of the total onsite energy, excluding feedstocks used by this industry. The chemicals industry used approximately 1,504 trillion Btu of energy to generate steam, which represents about 47% of the total onsite energy, excluding feedstocks used in this industry. The petroleum refining industry used about 915 trillion Btu of energy to generate steam, which accounts for about 28% of this industry’s total onsite energy use, excluding feedstocks.2

Steam System Operation

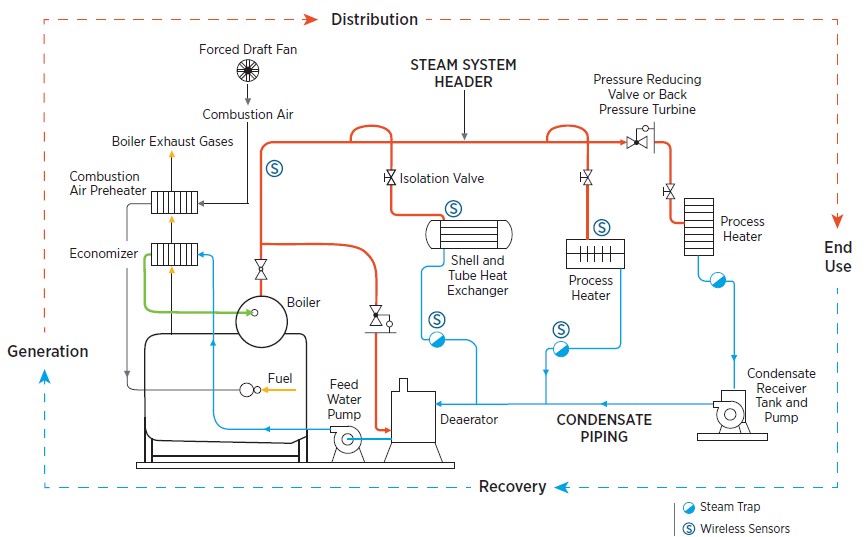

This course uses four categories to discuss steam system components and ways to enhance steam system performance: generation, distribution, end use, and recovery. These four areas follow the path of steam as it leaves the boiler and returns via the condensate return system.

Generation

Steam is generated in a boiler or a heat recovery steam generator by transferring the heat of combustion gases to water. When water absorbs enough heat, it changes phase from liquid to steam. In some boilers, a superheater further increases the energy content of the steam. Under pressure, the steam then flows from the boiler or steam generator and into the distribution system.

Distribution

The distribution system carries steam from the boiler or generator to the points of end use. Many distribution systems have several take-off lines that operate at different pressures. These distribution lines are separated by various types of isolation valves, pressure-regulating valves, and, sometimes, backpressure turbines. A properly performing distribution system delivers sufficient quantities of high-quality steam at the right pressures and temperatures to the end uses. Effective distribution system performance requires proper steam pressure balance, good condensate drainage, complete and optimum insulation with regular repair and maintenance, and effective pressure regulation.

End Use

There are many different end uses of steam. Examples of steam’s diverse uses include process heating, mechanical drive, moderation of chemical reactions, and fractionation of hydrocarbon components. Common steam system end-use equipment includes heat exchangers, turbines, fractionating towers, strippers, and chemical reaction vessels.

In a heat exchanger, the steam transfers its latent heat to a process fluid. The steam is held in the heat exchanger by a steam trap until it condenses, at which point the trap passes the condensate into the condensate return system. In a turbine, the steam transforms its energy to mechanical work to drive rotating machinery such as pumps, compressors, or electric generators. In fractionating towers, steam facilitates the separation of various components of a process fluid. In stripping applications, the steam pulls contaminants out of a process fluid. Steam is also used as a source of water for certain chemical reactions. In steam methane reforming, steam is a source of hydrogen.

Recovery

The condensate return system sends the condensate back to the boiler. The condensate is returned to a collection tank. Sometimes the makeup water and chemicals are added here, while other times this is done in the deaerator. From the collection tank the condensate is pumped to the deaerator, which strips oxygen and non-condensable gases. The boiler feed pumps increase the feedwater pressure to above boiler pressure and inject it into the boiler to complete the cycle.

Figure 1 provides a general schematic description of the four principal areas of a steam system. The following sections discuss the components in these areas in greater detail. Consider opportunities to cascade heat recovery from exhaust gases to lower temperature process heating equipment. Develop procedures for regular operations, calibration, and maintenance of process sensors (i.e., pressure, temperature, and flow) and controllers.

Steam System Basics – Recovery

The recovery components of a steam system collect and return condensate back to the generation part of the system. Condensate recovery provides thermal and water treatment benefits. Condensate that is not returned must be compensated for by the addition of makeup water, which is generally much cooler than condensate, however it is becoming less commonly available. Condensate temperature often exceeds 200°F, while makeup water temperature is typically between 50°F and 80°F. As a result, the enthalpy difference between condensate and makeup water is generally over 120 Btu/lb, an amount of energy that is often more than 10% of the energy in the boiler generated steam.

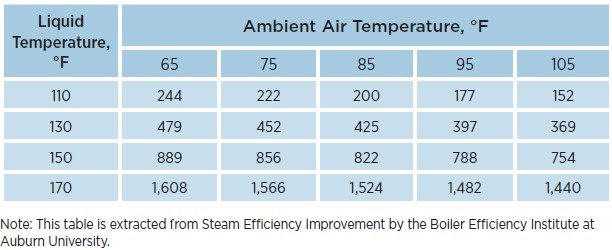

Additionally, makeup water is generally treated with chemicals that remove minerals and establish certain pH levels in the boiler water and in the system. Reducing the amount of makeup water added to the system reduces chemical use. Additionally, some of the treatment chemicals that are contained in condensate are problematic to a plant’s wastewater treatment facility. Industrial steam plants often extend across large areas. Recovering condensate from steam systems requires piping, collecting tanks, pumping equipment, and, in many cases, flash steam separators, meters, and filtration/cleanup equipment. However, the cost savings available from avoiding the purchase, treatment, and heating of makeup water often make investments in condensate recovery systems highly feasible.

Condensate Return Piping

Condensate return piping transports condensate as it drains from distribution and end-use equipment piping back to the boiler. Condensate piping should be adequately sized and insulated. Although the installation of larger pipe diameters is more expensive, larger pipes create less pressure drop for a given flow rate; this reduces the load on the condensate pumps. Larger pipe diameters also reduce the noise associated with condensate flow and are more suitable for carrying flash steam. Insulating the condensate piping helps to retain the thermal energy that provides much of the benefits of a condensate recovery system.

Insulation

Insulation provides energy savings and safety benefits. In terms of energy savings, insulation reduces heat loss from the condensate piping and recovery equipment surfaces, which can make the surrounding work environment more comfortable. Reducing this heat loss can also reduce the burden on the cooling systems that support surrounding workspaces. In terms of safety, insulation reduces the outer surface temperature of the piping, which lessens the risk of burns. Important insulation properties and characteristics of piping insulation are discussed in the Distribution section. See Tip Sheet #2, Insulate Steam Distribution and Condensate Return Lines at: manufacturing.energy.gov.

Condensate Receiver Tanks

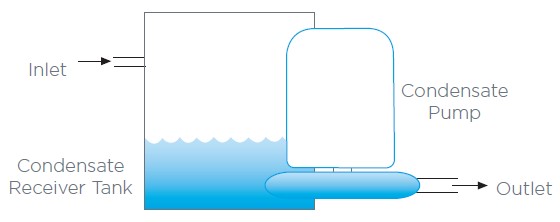

Condensate receiver tanks collect and store condensate. These tanks are usually located remotely around the condensate system and are configured in conjunction with condensate pumps, as shown in Figure 14. Condensate flows can be highly variable due to changes in steam demand, especially during system start-ups. Receiver tanks minimize the effects of this flow variability on condensate pumps by providing storage, which maintains a minimum water level that prevents downstream condensate pumps from running dry. Since many condensate pumps are centrifugal types, it is important to keep a certain suction pressure to prevent cavitation damage. By maintaining a minimum condensate level, receiver tanks provide enough static pressure to avoid cavitation.

Most systems also contain a large condensate receiver tank that collects all the condensate returned from the system. This tank may also be used to store pretreated water.

Condensate Pumps

Condensate pumps move condensate from receiver tanks back to the boiler room. Condensate pumps can be driven by electric motors, steam, or compressed air, depending on the availability of these sources. Motor-driven condensate pumps are usually centrifugal type pumps. In many cases, receiver tanks and motor-driven pumps are packaged together and equipped with a control system that de-energizes the pump under low water level conditions. Steam or compressed air powered condensate pumps are used where electrical pumps would not be suitable, and are generally pressure-powered pumps.

Condensate pumps also can be important to the performance of end-use equipment. Effective use of condensate pumps can eliminate condensate backup into end-use equipment, improving process control and reducing potential equipment problems from condensate acidification and water hammer.

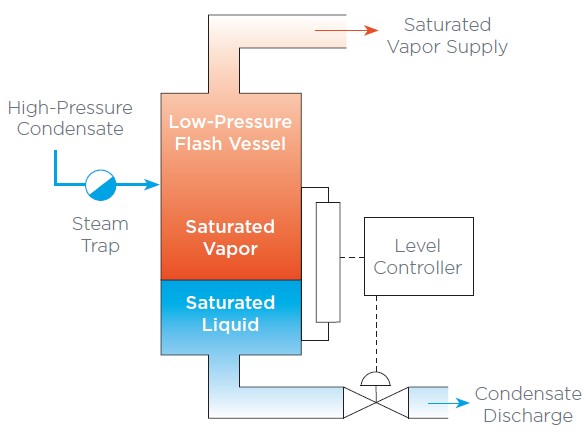

Flash Steam Vessels

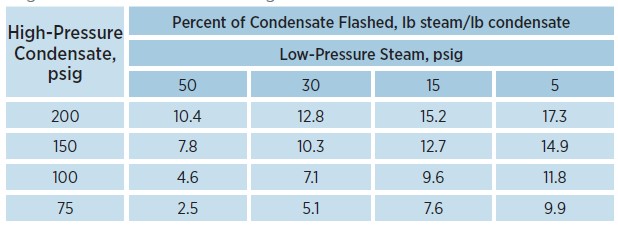

Flash steam vessels allow the recovery of steam from condensate lines, as illustrated in Figure 15. By removing steam from the condensate system, flash steam vessels provide an efficient source of steam to low-pressure end uses. For example, 250°F condensate has a saturation pressure of about 15 psig. Consequently, steam that is separated by flash steam vessels can be used in low-pressure steam applications such as space heating and preheating.

Condensate Meters

Condensate meters measure the flow rate of condensate in the return system. Knowing the condensate flow rate can be helpful in monitoring the condensate system and the condition of steam traps. Condensate meters are often inline rotary types, relying on turbine or scroll rotation to measure flow rate.

Filtration/Cleanup Equipment

In many systems, the flow of steam and condensate picks up rust, scale, and trace contaminants that are either carried over from the boiler or that form in carbon steel piping and on copper alloy heat exchange surfaces. Although strainers and filters are used to catch the particulate matter, some contaminants are dissolved in the condensate and can cause problems if returned to the boiler. In systems that require a high level of cleanliness, condensate polishers are used. Condensate polishers use ion exchange to remove these contaminants, preventing the redeposition of these contaminants on boiler surfaces.

Steam System Basics – End Use

Steam system end-use equipment transfers steam energy into other forms of useful energy. Common end-use equipment includes heat exchange devices to transfer thermal energy and turbines to recover mechanical energy. In manufacturing industries, steam end uses often directly support production, making their performance and reliability essential to plant productivity. Improvements in end-use efficiency and effectiveness also tend to result in better performance and increased reliability. There is a wide range of end-use equipment, largely because of the advantages of steam that are discussed in the Introduction. Some of the major end-use components are discussed in this section.

For the purposes of this discussion, steam end-use equipment is grouped into three basic categories:

- Industries of key end-use equipment in Energy Intensive Industries

- Conditioning and control equipment

- Additional equipment

The key equipment category includes the largest uses of steam in those industries. Although facilities use steam for other services as well, the key end uses account for the largest amount of steam use. The conditioning equipment category includes equipment that facilitates the effective use of steam. The additional equipment category includes equipment that is used in other industries and, though significant, does not account for most of the steam use in energy intensive industries.

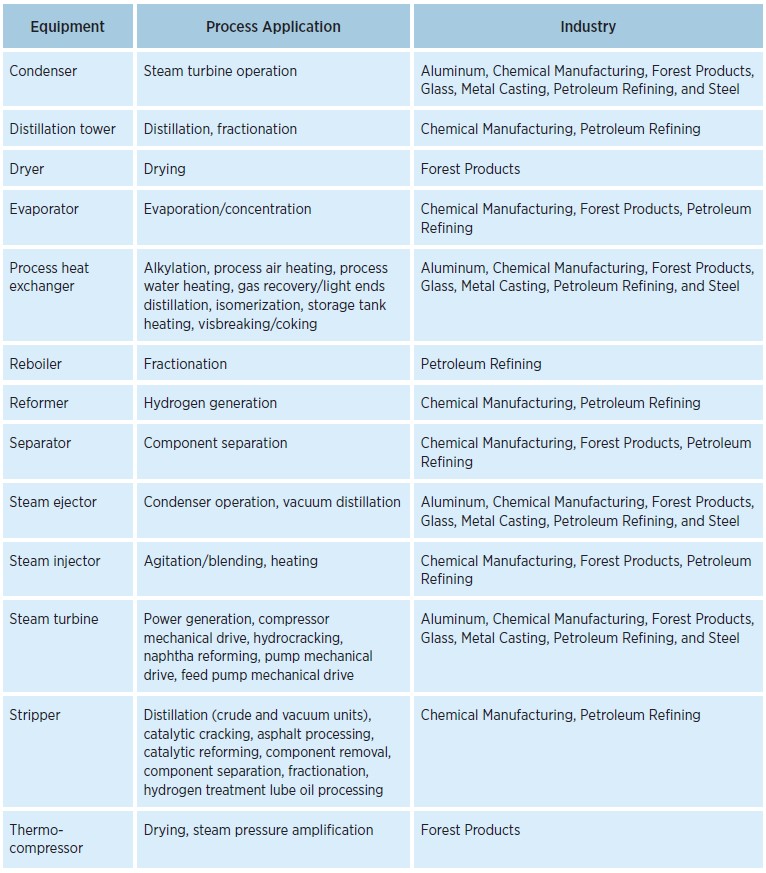

Key End-Use Equipment in Energy Intensive Industries

In the three industries of forest products, petroleum refining, and chemicals, steam accounts for the largest amount of end-use energy. In integrated steel production, steam represents a significant amount of end-use energy and is used to generate most of that industry’s on-site electric power. Table 1 provides a list of key steam-supplied end-use equipment for energy intensive industries.

Condensers

In steam applications, condensers are associated with condensing steam turbines and with multiple stage ejector systems. In steam turbine applications, condensers typically operate under a vacuum. They remove energy from the exhaust steam, allowing it to be recovered as condensate. In steam ejector applications, condensers increase the effectiveness of the ejectors by condensing both the motive steam and condensables pulled from the process, reducing the amount of motive steam required.

Condensers can be surface type or barometric. Surface condensers are supplied with cooling water that circulates through condenser tubes, providing a cool surface area that causes steam condensation. The condensate is typically collected in a condensate well, and pumped into the condensate return system. Barometric condensers rely on direct contact between the cooling water and the steam. In petroleum refining and chemical manufacturing applications, condensers are also used to condense components from gaseous mixtures. In these applications, the condensers use a cooling medium to extract energy from the gases and collect the condensed components.

Distillation Towers

The petroleum refining and chemical manufacturing industries use large amounts of steam to facilitate the separation of crude oil or chemical feedstocks into various components. This separation process relies on differences in the boiling points of these hydrocarbon components. Fractionating towers use a furnace to heat crude oil above 700°F. As the volatile components boil off and rise up the tower, they cool and condense on trays. Steam is injected into the bottom of these towers to reduce the partial pressures of the hydrocarbons, which facilitates their separation, and to reduce coke formation on tray and tower surfaces.

Dryers

Dryers reduce the water content of a solid. Dryers account for the largest end use of steam in the pulp and paper industry.9 The chemical manufacturing, textiles, and food processing industries also use large amounts of steam for drying. Dryers can be indirect or direct. Indirect dryers remove moisture thermally as energy is transferred from condensing steam, flue gases, or high temperature process fluid to the product being dried. Common indirect dryer types are coil and rotating drum. Direct dryers use hot gases that have been heated with steam or flue gases to directly contact and dry a product.

Dryers, like evaporators, can be arranged in multiple- stage configurations. Multiple-stage steam dryers use

a cascading set of steam pressures, allowing steam released from an upstream stage to supply steam to

the next stage. In many multiple-stage dryers, thermo-compressors are used to increase the steam pressure of downstream-effect stages.

Evaporators

Evaporators reduce the water content of a liquid, generally by heating it with steam to concentrate the product. Evaporators are used extensively in industries such as food processing, chemical manufacturing, steel, forest products, and textiles.

In most cases, evaporators are shell and tube heat exchangers with the steam on the shell side and the product being concentrated in the tubes. Evaporators can be single effect or multiple effect. A single-effect evaporator uses steam at one set of pressure and temperature conditions to boil off the vapor from a product. Multiple-effect evaporators take the vapor produced from one evaporator and use it to heat the product in a lower-pressure evaporator. Multiple-effect evaporators are generally more efficient at concentrating a fluid than single-effect evaporators.

Heat Exchangers

Heat exchangers transfer thermal energy from one fluid to another. In manufacturing facilities, steam is a common source of heat for many reasons, some of which are discussed in the Introduction. There is a wide range of heat exchanger designs that use steam, largely due to the wide range of products that are heated with steam.

Many process and product considerations must be incorporated into the selection of a heat exchanger. Some basic heat exchanger types are discussed below, including:

- Tubular

- Plate and frame

- Jacketed

- Coil.

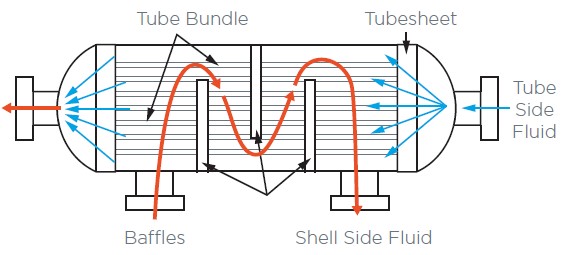

Tubular heat exchanger. Tubular heat exchangers are tube bundles that are surrounded by the heated or heating medium. This type of heat exchanger includes finned tube and shell and tube designs as shown in Figure 10. Finned tube heat exchangers are often used to heat air for drying and space heating applications. Shell and tube heat exchangers are often used for liquid heating and evaporation. Since the tube side of shell and tube heat exchangers can be designed to withstand high pressures, sometimes exceeding 1,500 psig, heat exchangers of this type are often used in high-temperature and high-pressure applications.

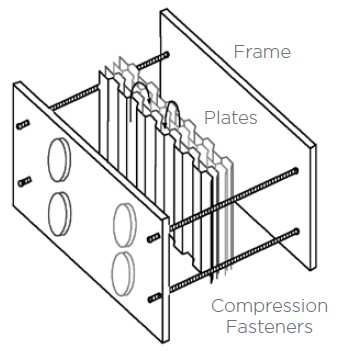

Plate and frame heat exchanger. In plate and frame heat exchangers, the two heat exchange fluids are separated by plates. The plates are corrugated, or ridged, as shown in Figure 11, to increase the surface area available for heat transfer. Plate and frame heat exchangers are often used in low-viscosity applications, where the risk of clog-ging is less severe. The plate ends are typically sealed by covers with gaskets covers that can be removed to allow disassembly and cleaning. This heat exchanger type is used when temperatures and pressures are moderately low, typically below 300°F and 370 psi. Plate and frame heat exchangers also have a common design variation that has the plates welded or brazed together. This allows higher temperature service but eliminates the possibility of mechanical cleaning.

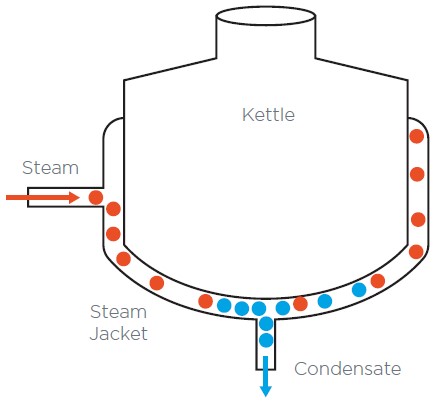

Jacketed heat exchangers. Jacketed heat exchangers use an enclosure to surround the vessel that contains the heated product. A common example of a jacketed heat exchanger is the jacketed kettle. A representation of a jacketed heat exchanger is shown in Figure 12. Jacketed heat exchangers are practical for batch processes and for product types that tend to foul or clog tube bundles or coils.

Heat Exchanger

Coil heat exchangers. Coil heat exchangers characteristically use a set of coils immersed in the medium that is being heated. Coil heat exchangers are generally compact, offering a large heat transfer area for the size of the heat exchanger.

Reboilers

Reboilers are typically used in distilling processes to increase component separation. Reboilers use heat, often provided by steam, to evaporate the volatile components of a product that has been drawn from a fractionating tower. These volatile components are sent downstream for further processing. The residual components are sent back into the fractionating tower or sent on to a vacuum distillation process. There are several types of reboilers, including jacketed kettle, kettle, internal reboiler, and thermosyphon reboiler. These designs differ from one another in the way the product is heated with steam.

Reformers

Steam reformers are used to generate hydrogen, typically from a hydrocarbon feedstock such as methane (the largest component of natural gas). In turn, hydrogen is used in many petroleum refining and chemical manufacturing processes. Reformers use steam for both energy and as a source of hydrogen. Steam is injected with the hydrocar-bon feedstock to initiate the following reaction:

Reformers often have secondary stages that are used to convert the carbon monoxide to carbon dioxide and additional hydrogen. Although large amounts of steam are used throughout the reforming processes, steam is also generated by the reformers and is sometimes exported for other uses.

Steam Ejectors

Steam ejectors use steam flow through a nozzle to create a vacuum (similar in operation to thermocompressors). They are used in several different types of system applications and process equipment. Low-pressure conditions promote the evaporation of liquids at reduced temperatures.

Consequently, many chemical manufacturing processes use steam ejectors to increase the concentration of a product. In petroleum refining, steam ejectors are commonly used in the vacuum distillation of heavy hydrocarbon products. Steam ejectors are also used to initiate and maintain vacuum condition in the condensers of condensing turbines.

Steam Injectors

Steam injectors are used to inject steam directly into a tank or a pipe containing a process fluid, generally for heating purposes. Many injector types use a nozzle and a diffuser to pull process fluid into the steam before the mixture is injected into the process fluid, to promote an even distribution of heat. Important performance characteristics of injectors include accurate control of the amount of steam injected and effective mixing of the steam and process.

Steam Turbines

Steam turbines are used to drive electric generators or other rotating machinery such as compressors, pumps, and fans. Steam turbines are used in many different system designs, depending on the relative requirements for steam, electricity, or other mechanical loads. Steam turbines pro-vide an effective means of stepping down steam pressure while extracting mechanical work.

Some turbines have interstage take-offs that allow steam to be extracted at various pressures before reaching the turbine exhaust. These extractions provide flexibility in meeting competing requirements of both the steam system and the mechanical load. For example, if the turbine is connected to an electric generator, adjusting the amount of extracted steam can allow more or less electric power to be generated, while making respectively less or more steam available to the plant.

Backpressure turbines. Backpressure turbines exhaust steam at pressures that are higher than atmospheric, and the exhaust steam is then used for other services. By extracting mechanical work from steam, backpressure tur-bines can provide an efficient means of supplying lower-pressure steam from a high-pressure header.

Condensing turbines. Condensing turbines exhaust steam to vacuum (sub-atmospheric) conditions. This steam is condensed in a heat exchanger, referred to as a condenser, and transferred to the condensate return system. Condensing turbines typically require a source of cooling water to condense the steam.

Strippers

Steam strippers are used to remove contaminants from a solution. Strippers are commonly found in petroleum refining and chemical manufacturing applications, where process solutions contain components that have different boiling points and removal of one or more of the components is necessary. Injecting steam into the process solution lowers the partial pressure of volatile components, allowing some of them to vaporize and get transported away with the steam. Steam can also raise the temperature of the mixture, lowering the solubility of the objectionable material and causing it to strip off with the steam. Often, the steam and the contaminants are condensed and separated, allowing recovery of the condensate and disposal or further processing of the contaminant.

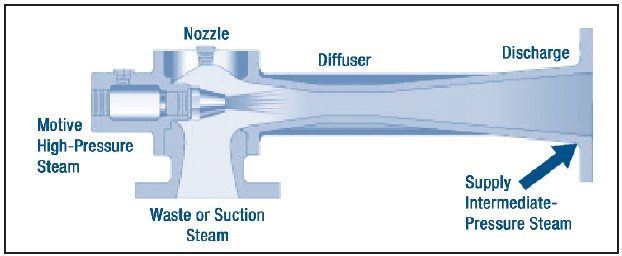

Thermocompressors

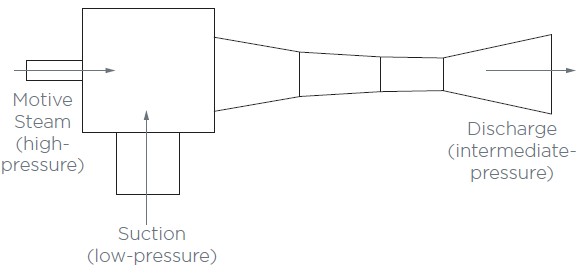

Thermocompressors combine high-pressure and low-pressure steam to form an intermediate-pressure steam supply (see Figure 13). Often the low-pressure steam does not have enough energy to be feasibly used; however, discharging it to the condensate return system can be an unnecessary energy loss. Thermocompressors use a high-pressure steam source to recover the energy from this low-pressure source, providing an intermediate steam supply that can be feasibly used.

Conditioning and Control Equipment

Conditioning equipment is generally used to improve the performance of, or to protect the end-use equipment. For example, desuperheaters are often used to control the energy of a steam supply to end-use equipment to reduce the risk of damage to the equipment or to effectively improve temperature control of the process.

Desuperheaters. The purpose of a desuperheater is to remove the superheat from steam. The majority of heating and process equipment performs more efficiently using saturated rather than super-heated steam. Desuperheaters inject a very fine mist of high-purity water, such as condensate, into the steam flow. The superheated vapor gives up heat to the water mist, and by doing so, reduces its temperature.

Vacuum breakers. Vacuum conditions can develop in a steam system when steam flow into a component or a branch is throttled or shut off. If the rate of downstream steam use exceeds the steam supply, the pressure decreases and vacuum conditions can form. Vacuum conditions also result when the load on the heat exchanger is significantly less than the heat exchanger capacity. If the pressure in the heat exchanger drops too far, the condensate will not drain from the trap due to a higher pressure on the trap’s downstream side. If uncorrected, the condensate level will rise in the heat exchanger, reducing the available heat transfer area and increasing the risk of corrosion by condensate. Vacuum breakers are pressure-controlled devices that essentially vent a heat exchanger or system branch in which a vacuum has formed. By allowing in air when they open, vacuum breakers restore pressure and allow the condensate to drain.

Air vents. Before start-up, the steam system contains air that must be removed. The presence of air in a steam system reduces heat transfer effectiveness and promotes condensate corrosion. Air vents remove this air. Air vents are often thermostatic devices, similar to thermostatic steam traps that rely on the temperature difference between air and steam. When exposed to the lower temperature air in the system side, the vent opens. As the higher temperature steam reaches the vent, it closes, preventing the escape of steam.

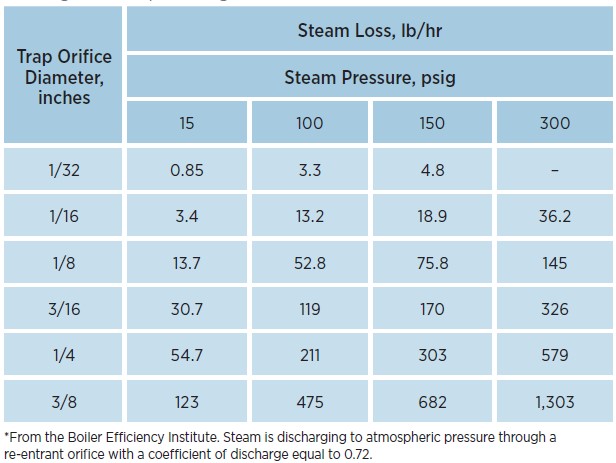

Traps. Steam traps are important to the performance of end-use equipment. Traps provide for condensate removal with little or no steam loss. If the traps do not function properly, excess steam will flow through the end-use device or the condensate will back up into it.

Excess steam loss will lead to costly operation, while condensate backup will promote poor performance and may lead to water hammer. Traps can also remove noncondensable gases that reduce heat exchanger effectiveness. There are several different types of steam traps, which are dis-cussed in the Distribution section of this course.

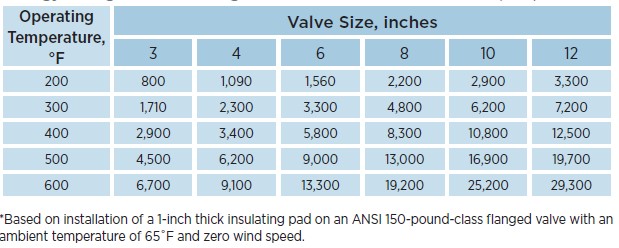

Insulation

End-use equipment, such as heat exchangers and turbines, should generally be insulated due to the significant heat loss that the surface areas of this equipment can pro-vide. The various types of insulation are discussed in the Distribution section. Where end-use equipment requires frequent inspection or maintenance, removable insulation should be considered.

Additional Equipment

The additional equipment category refers to end uses of steam throughout industry; although still significant, these generally account for less steam energy than key end uses.

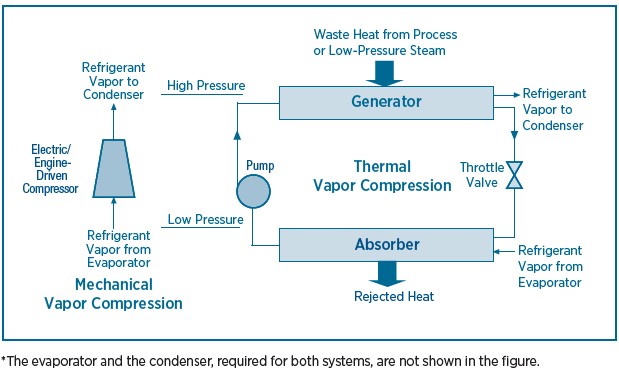

Absorption chillers. Absorption chillers provide cooling using an interesting variation of the vapor compression cycle. Instead of a compressor, which is generally used in chillers, absorption chillers exploit the ability of one sub-stance to absorb a refrigerant at one temperature and then release it at another. In ammonia-based systems, water is the absorbent and ammonia is the refrigerant. In lithium bromide-based systems, lithium bromide is the absorbent, while water is the refrigerant. An absorption chiller uses a pump instead of a compressor to increase refrigerant pressure. Once it is at the higher pressure, the absorbent/refrigerant solution is heated, often with steam, which releases the refrigerant. Although absorption chillers generally have lower coefficients of performance (COP) (indicating lower thermodynamic efficiency) than traditional chillers, they use less electric power per ton of cooling and are well suited for use with steam systems.

Humidifiers. Humidifiers inject steam into an air or other gas source to increase its water vapor content. In humidification, steam is used as a source of both water and energy. Humidification applications are found in the chemical manufacturing industry where control of ambient temperature and moisture content are critical for product quality.

Preheat/Reheat air handling coils. While steam is occasionally used in space heating applications to preheat and reheat air, there are other more efficient methods of con-trolling space humidity levels. In many HVAC systems, the conditioned air must have both its temperature and humidity adjusted. In preheat applications, steam is used to heat an air supply, which is typically a mixture of return air and outside air. The air is then conditioned to achieve a certain humidity and temperature. In reheat applications, the air is cooled to a particular dew point to remove water and achieve a desired humidity. As a result, before the air is delivered back to the workspaces, steam coils must reheat the process air stream up to the proper temperature. In both reheat and preheat applications, finned tube heat exchangers are generally used.

Tracing. In tracing applications, steam is used to maintain the temperature of a fluid in a pipe. A common application of tracing lines is to prevent the freezing of a process fluid in piping that runs outside of a temperature-controlled area. Since tracing lines are exposed to freezing conditions, proper insulation, steam flow, and condensate drain-age are essential to prevent freezing of the tracing lines as well as the process piping.

Meters. Steam meters are used to measure steam flow, and are important for tracking the steam use of a particular part of a steam system or a particular end use. Discussion of different meter types is provided in the Steam Generation section.

Steam System Basics – Distribution

The distribution system transports steam from the boiler to the various end uses. Although distribution systems may appear to be passive, in reality, these systems regulate the delivery of steam and respond to changing temperature and pressure requirements. Consequently, proper performance of the distribution system requires careful design practices and effective maintenance. The piping should be properly sized, supported, insulated, and configured with adequate flexibility. Pressure-regulating devices such as pressure-reducing valves and backpressure turbines should be configured to provide proper steam balance among the different steam headers. Additionally, the distribution system should be configured to allow adequate condensate drainage, which requires adequate drip leg capacity and proper steam trap selection. Steam distribution systems can be broken down into three different categories: buried pipe, above-ground, and building sections, and selection of distribution components (piping, insulation, etc.) can vary depending on the category.

Selected Energy Efficiency Practices for Steam Distribution Systems

- Validate energy intensity baseline and improvements with ASME Steam System Assessment Standard.

- Locate improved profit opportunities with data sources, such as wireless sensors, near your largest steam traps.

- Configure distribution systems to include adequate condensate drainage in startup and operating modes, for flash steam recovery and for optimized condensate return to the boiler.

Piping

Steam piping transports steam from the boiler to the end-use services. Important characteristics of well-designed steam system piping are that it is adequately sized, configured, and supported. Installation of larger pipe diameters may be more expensive, but can create less pressure drop for a given flow rate. Additionally, larger pipe diameters help to reduce the noise associated with steam flow. As such, consideration should be given to the type of environment in which the steam piping will be located when selecting the pipe diameter. Important configuration issues are flexibility and drainage. With respect to flexibility, piping (especially at equipment connections), needs to accommodate thermal reactions during system start-ups and shutdowns. Additionally, piping should be equipped with a sufficient number of appropriately sized drip legs to promote effective condensate drainage. Additionally, the piping should be pitched properly to promote the drainage of condensate to these drip lines. Typically, these drainage points experience two very different operating conditions, normal operation and start-up; both load conditions should be considered in the initial design.

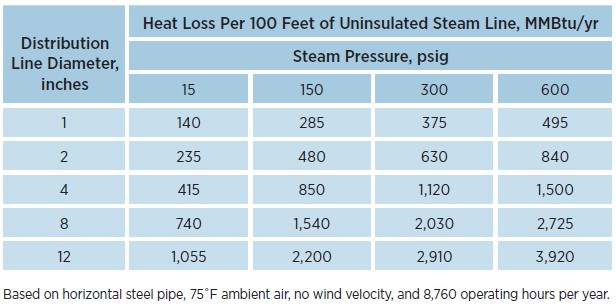

Insulation

Thermal insulation provides important safety, energy savings, and performance benefits. In terms of safety, insula-tion reduces the outer surface temperature of the steam piping, which lessens the risk of burns. A well-insulated system also reduces heat loss to ambient workspaces, which can make the work environment more comfortable. Consequently, the energy saving benefits include reduced energy losses from the steam system and reduced burden on the cooling systems that remove heat from workspaces. In addition to its safety and energy benefits, insulation increases the amount of steam energy available for end uses by decreasing the amount of heat lost from the distribution system. See the Mechanical Insulation Design Guide, at www.wbdg.org/midg, for more on steam system insulation.

Important insulation properties include thermal conductivity, strength, abrasion resistance, workability, and resistance to water absorption. Thermal conductivity is the measure of heat transfer per unit thickness. Thermal conductivity of insulation varies with temperature; consequently, it is important to know the right temperature range when selecting insulation. Strength is the measure of the insulation’s ability to maintain its integrity under mechanical loads. Abrasion resistance is the ability to withstand shearing forces. Workability is a measure of the ease with which the insulation is installed. Water absorption refers to the tendency of the insulation to hold moisture. Insulation blankets (fiberglass and fabric) are commonly used on steam distribution components (valves, expansion joints, turbines, etc.) to enable easy removal and replacement for maintenance tasks.

Some common insulating materials used in steam systems include calcium silicate, mineral fiber, fiberglass, perlite, and cellular glass. The American Society for Testing and Materials (ASTM) provides standards for the required properties of these and other insulation materials. Additionally, the North American Insulation Manufacturers Association (NAIMA) has developed a software program titled 3E Plus that allows users to determine the energy losses associated with various types and thicknesses of insulation. The 3E Plus program facilitates the assess-ment of various insulation systems to determine the most cost-effective solution for a given installation. See Section 2, for more about 3E Plus Insulation software, which can help steam users assess insulation opportunities.

Selected Energy Efficiency Practice for Valves

- Locate improved profit opportunities with data sources, such as wireless sensors, near your largest valves.

- Use backpressure turbines, where possible, to avoid energy losses associated with pressure reductions through valves.

Valves

In steam systems, the principal functions of valves are to isolate equipment or system branches, to regulate steam flow, and to prevent over-pressurization. The princi-pal types of valves used in steam systems include gate, globe, swing check, pressure reducing, and pressure relief valves. Gate, globe, and swing check valves typically isolate steam from a system branch or a component.

Pressure reducing valves (PRV) typically maintain certain downstream steam pressure conditions by controlling the amount of steam that is passed. These reducing valves are often controlled by transmitters that monitor downstream conditions. Pressure relief valves release steam to prevent over-pressurization of a system header or equipment.

Steam Separators

In some steam systems, wet steam is generated. This wet steam contains water droplets that can reduce the effectiveness of the steam system. Water droplets erode piping elbows, turbine blades and passages, and pressure reducing valves, thus reducing efficiency and life. Furthermore, liquid water can significantly reduce heat transfer rates in heat exchange components, as well as result in water ham-mer. Removing water droplets before they reach end-use equipment is necessary.

Steam separators remove water droplets, generally relying on controlled centrifugal flow. This action forces the entrained moisture to the outer wall where it is removed from the separator. The means of moisture removal could be a steam trap or a drain. Some manufacturers include the trap as an integral part of the unit. Additional accessories include water gauge connections, thermometer connections, and vent connections.

Steam separators can be installed in either a horizontal or vertical line. They are capable of removing 99% of particulate entrainment 10 microns and larger over a wide range of flows. Separators are often designed in accordance with ASME Code, Section VIII, Division 1, with pressures to 300 psig.

Steam Accumulators

A steam accumulator is a large insulated pressure vessel, partially filled with hot water (saturated liquid). When steam supply exceeds demand, the excess high-pressure steam is charged into the accumulator through special charging nozzles. The steam is condensed, giving up its latent heat, to raise the pressure, temperature, and heat con-tent of the water body. When the steam demand exceeds the supply, the pressure in the accumulator drops and the additional required steam flashes from the water, taking back the heat previously stored. A simple system of control valves and check valves regulates the charging and discharging. The excess steam is charged quietly and smoothly, and when steam is needed, it is available with the speed of a control valve operation. There is also an accumulator design that stores hot water for use as boiler feedwater.

Steam Traps

Steam traps are essential for proper distribution system performance. During system start-ups, traps allow air and large quantities of condensate to escape. During system operation, the traps allow collected condensate to pass into the condensate return system, while minimizing the accompanying loss of steam. There are three primary types of traps: thermostatic, mechanical, and thermodynamic.

Selected Energy Efficiency Practices for Steam Traps

- Validate energy intensity improvement opportunities with ASME Steam System Assessment Standard.

- Improve profits with data from wireless sensors at steam traps by continuously monitoring and alarming for leakage. If you try one, chances are you’ll want more. Favorable returns on investments have been reported in their use.

- Several types of steam traps, including mechanical traps, are highly sensitive to correct installation arrangement and even insulation quantity to operate properly. Follow the installation and insulation guidance of the trap manufacturer carefully.

Thermostatic Traps

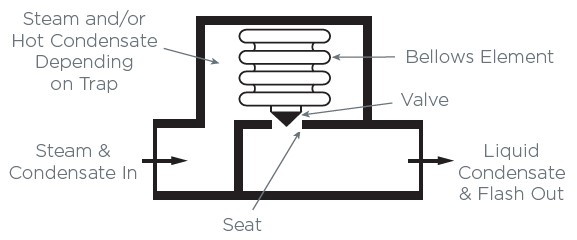

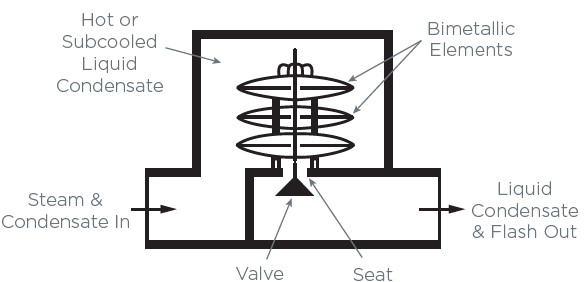

Thermostatic traps use temperature differential to distinguish between condensate and live steam. This differential is used to open or close a valve. Under normal operating conditions, the condensate must cool below the steam temperature before the valve will open. Common types of thermostatic traps include bellows and bimetallic traps.

Bellows traps. Bellows traps include a valve element that expands and contracts in response to temperature changes. Often a volatile chemical such as alcohol or water is inside the element. Evaporation provides the necessary force to change the position of the valve. At start-up, the bellows trap is open due to the relative cold condition. This operating condition allows air to escape and provides maximum condensate removal when the load is the highest. Bellows traps can fail either open or closed. The configuration of a bellows steam trap is shown in Figure 5.

Bimetallic traps. Bimetallic traps rely on the bending of a composite strip of two dissimilar metals to open and close a valve. Air and condensate pass freely through the valve until the temperature of the bimetallic strip approaches the steam temperature. After steam or relatively hot condensate heats the bimetallic strip and causes it to close the valve, the trap remains shut until the temperature of the condensate cools sufficiently to allow the bimetallic strip to return to its original shape and thereby open the valve. Bimetallic traps can fail in either the open or closed position. The con-figuration of a bimetallic steam trap is shown in Figure 6.

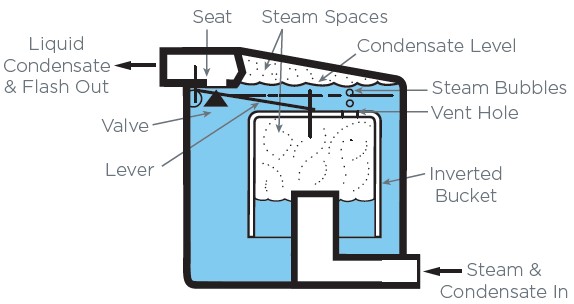

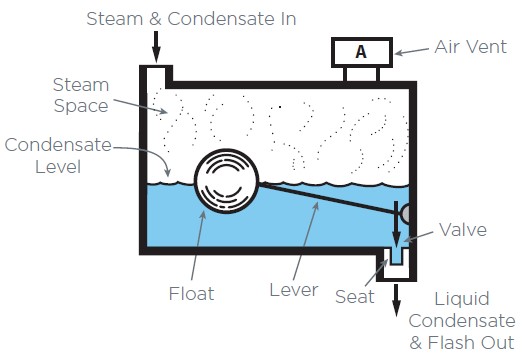

Mechanical Traps

Mechanical traps use the difference in density between condensate and live steam to produce a change in the position of a float or bucket. This movement causes a valve to open or close. There are a number of mechanical trap designs that are based on this principle. They include ball float, float and lever, inverted bucket, open bucket, and float and thermostatic traps.

Ball float traps. Ball float traps rely on the movement of a spherical ball to open and close the outlet opening in the trap body. When no condensate is present, the ball covers the outlet opening, thereby keeping air and steam from escaping. As condensate accumulates inside the trap, the ball floats and uncovers the outlet opening. This movement allows the condensate to flow continuously from the trap. Unless they are equipped with a separate air vent, ball float traps cannot vent air on start-up.

Float and lever traps. Float and lever traps are similar in operation to ball float traps except the ball is connected to a lever. When the ball floats upward due to accumulation of condensate inside the trap body, the attached lever moves and causes a valve to open. This action allows condensate to continuously flow from the trap. If the condensate load decreases and steam reaches the trap, downward ball movement causes the valve to close, thereby keeping steam from escaping. Unless they are equipped with a separate air vent, float and lever traps cannot vent air on start-up. See the discussion on float and thermostatic traps.

Inverted bucket traps. Inverted bucket traps are some-what more complicated than float and lever traps. At start-up, the inverted bucket inside the trap is resting on the bottom of the trap body and the valve to which the bucket is linked is wide open. The trap is initially filled with condensate. As steam enters the trap and is captured inside the bucket, it causes the bucket to move upward. This upward movement closes the valve and keeps steam from escaping. When the condensate collects and cools the steam, the bucket moves downward. This movement causes the valve to open, thereby allowing the condensate to escape. Unlike closed float traps, inverted bucket traps have intermittent discharge. These traps can be depleted of their condensate seal when applied in superheated steam service. If this occurs, the trap will continuously discharge live steam. This trap type is not recommended for superheated steam service, unless special installation conditions are met. The configuration of an inverted bucket steam trap is shown in Figure 7.

Open bucket traps. Open bucket traps consist of an upright bucket that is attached to a valve. At start-up, the bucket rests on the bottom of the trap body. In this position, the valve is wide open. As condensate accumulates in the trap body on the outside of the bucket, the bucket floats upward, causing the valve to close. When sufficient condensate accumulates outside the bucket, it spills over the top and fills the inside of the bucket. At this time, the bucket sinks, causing the valve to open. This trap is also prone to failure when applied in superheated steam service because of the loss of the condensate seal. Like inverted bucket traps, open bucket traps have intermittent discharge.

Float and Thermostatic (F&T) traps. Float and thermostatic (F&T) traps are similar to float and lever traps except they include a thermostatic element that allows air to be discharged at start-up and during operation. The thermostatic elements used in these traps are the same as those used in thermostatic traps. The configuration of a float and thermostatic steam trap is shown in Figure 8.

Thermodynamic Traps

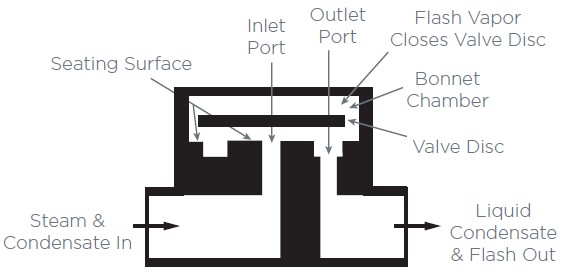

Thermodynamic traps use the difference in kinetic energy (velocity) between condensate and live steam to operate a valve. The disc trap is the most common type of thermodynamic trap, but piston or impulse traps are sometimes used.

Disc traps. Disc traps use the position of a flat disc to control steam and condensate flow. When condensate flows through the trap, the disc is raised, thereby causing the trap to open. As steam and air pass through the trap, the disc moves downward. The force that causes the disc to move downward is generated by the difference in pressure between the low-velocity steam above the disc and the high-velocity steam that flows through the narrow gap beneath the disc. Disc traps commonly have an intermit-tent discharge and, when they fail, they normally fail open. The configuration of a disc steam trap is shown in Figure 9. Generally, the air removal capability of this trap type is poor unless equipped with additional components (like the float and thermostatic trap).

Piston traps. Piston or impulse traps utilize the heat energy in hot condensate, and the kinetic energy in steam, to open and close a valve. Like disc traps, piston traps are phase detectors that sense the difference between a liquid and gas or vapor. They continuously discharge any air and condensate. Their primary failure mode is open.

Lever traps. Lever traps are a variation of the thermodynamic piston trap. They operate on the same principal as a piston trap but with a lever action to pass large amounts of condensate and air on a continuous basis. Their primary failure mode is open.

Orifice traps. Orifice traps are of two basic types: orifice plate and short tube. Both trap types operate under the exact same principles. A simple orifice plate steam trap consists of a thin metal plate with a small-diameter hole (orifice) drilled through the plate. When installed, condensate that accumulates is continuously removed as the steam pressure forces the condensate through the orifice. During conditions when no condensate is present, a limited amount of steam flows through the orifice. The report Review of Orifice Plate Steam Traps in the Where to Find Help section provides information for making informed decisions about when orifice plate steam traps should be considered for use in new or existing steam systems.

Steam Meters

The use of flowmeters within the distribution system can provide important data for monitoring the efficiency of

a process or an end use. Tracking the amount of steam required can be particularly useful in benchmarking efforts. The types of steam flowmeters are discussed in the Generation Section. The DOE Federal Energy Management Program has a Metering Best Practices Guide, Release 2.0, which includes steam use.

Steam System Basics – Generation

The generation part of a steam system uses a boiler to add energy to a feedwater supply to generate steam.

The energy is released from the combustion of fossil fuels or from process waste heat. The boiler provides a heat transfer surface (generally a set of tubes) between the combustion products and the water. The most important parts of the generating system include the boiler, the fuel supply, combustion air system, feedwater system, and exhaust gases venting system. These systems are related because problems or changes in one generally affect the performance of the others. DOE research partnerships with the industry have resulted in high-efficiency burners and other technologies for industrial boilers.

Boilers

There are two basic types of boilers: firetube and water-tube. The fundamental difference between these boiler types is which side of the boiler tubes contain the combustion gases or the boiler water/steam.

Firetube boilers. In firetube boilers, the combustion gases pass inside boiler tubes, and heat is transferred to water between the tubes and the outer shell. A representative firetube boiler is shown in Figure 2. Scotch marine boilers are the most common type of industrial firetube boiler. The Scotch marine boiler is an industry workhorse due to low initial cost and advantages in efficiency and durability.

Scotch marine boilers are typically cylindrical shells with horizontal tubes configured such that the exhaust gases pass through these tubes, transferring energy to boiler water on the shell side.

Selected Energy Efficiency Practices for Steam Systems and Boiler Operations

- Validate energy intensity improvements with Superior Energy Performance and ANSI or ISO Energy Management Standard.

- Locate savings opportunities and validate energy savings with data from interval monitoring or metering.

- Continuously maintain efficient systems by matching boiler capacities and operations to process load and loading cycles.

Scotch marine boilers contain relatively large amounts of water, which enables them to respond to load changes with relatively little change in pressure. However, since the boiler typically holds a large water mass, it requires more time to initiate steaming and more time to accommodate changes in steam pressure. Also, Scotch marine boilers generate steam on the shell side, which has a large surface area, limiting the amount of pressure they can generate. In general, Scotch marine boilers are not used where pressures above 300 pounds per square inch gauge (psig) are required. Today, the biggest firetube boilers are over 1,500 boiler horsepower (about 50,000 pounds per hour4).

Firetube boilers are often characterized by their number of passes, referring to the number of times the combustion (or flue) gases flow the length of the pressure vessel as they transfer heat to the water. Each pass sends the flue gases through the tubes in the opposite direction. To make another pass, the gases turn 180 degrees and pass back through the shell. The turnaround zones can be either dryback or waterback. In dryback designs, the turnaround area is refractory-lined. In waterback designs, this turn-around zone is water-cooled, eliminating the need for the refractory lining.

Watertube Boilers. In watertube boilers, boiler water passes through the tubes while the exhaust gases remain in the shell side, passing over the tube surfaces. A representative watertube boiler is shown in Figure 3. Because tubes can typically withstand higher internal pressure than the large chamber shell in a firetube, watertube boilers are used where high steam pressures (3,000 psi, sometimes higher) are required. Watertube boilers are also capable of high efficiencies and can generate saturated or superheated steam. In fact, the ability of watertube boilers to generate superheated steam makes these boilers particularly attractive in applications that require dry, high-pressure, high-energy steam, including steam turbine power generation. Another type of watertube boiler is a coil type watertube boiler shown in Figure 4.

The performance characteristics of watertube boilers make them highly favorable in process industries, including chemical manufacturing, pulp and paper manufacturing, and refining. Although firetube boilers account for the majority of boiler sales in terms of units, watertube boilers account for the majority of boiler capacity.

Waste Heat Recovery Boiler (WHRB). These boilers may be either firetube or watertube design and use heat that would otherwise be discarded to generate steam. Typical sources of heat for WHRBs include exhaust gases or high-temperature products from an external manufacturing process in refineries and chemical manufacturing facilities, or combustion of a waste fuel in the boiler furnace.

Heat Recovery Steam Generators (HRSGs). HRSGs transfer energy from the exhaust of a gas turbine to an unfired or supplementary fired heat-recovery steam generator to produce steam. Exhaust gases leave the gas turbine at temperatures of 1,000°F (538°C) or higher and can represent more than 75% of the total fuel energy input. This energy can be recovered by passing the gases through a heat exchanger (steam generator) to produce hot water or steam for process needs. If the amount of steam needed by the process exceeds the amount produced by simple heat recovery, then supplementary fuel can be burned in an inline duct burner between the gas turbine and the HRSG.

Superheaters. Superheaters add energy to steam, resulting in a steam temperature that exceeds the saturation temperature at a specific pressure, which is typically known as superheated steam. Superheaters can be convective or radiant. Radiative superheaters rely on the energy transferred directly from the combustion flame to increase the energy level of the steam, while convective superheaters rely on the transfer of additional energy from the flue gases to the steam.

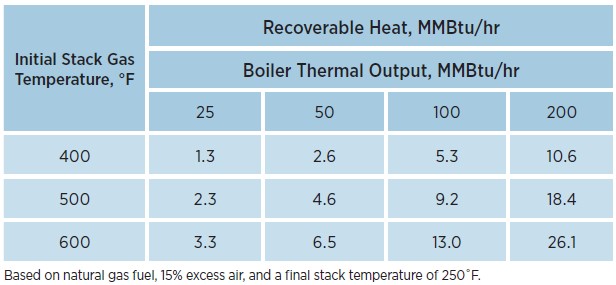

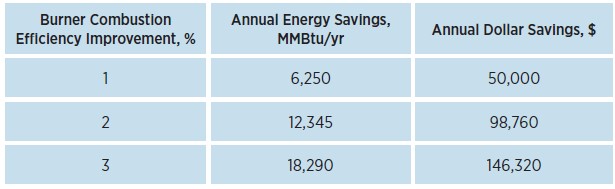

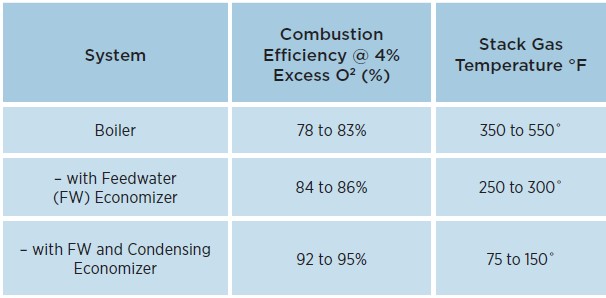

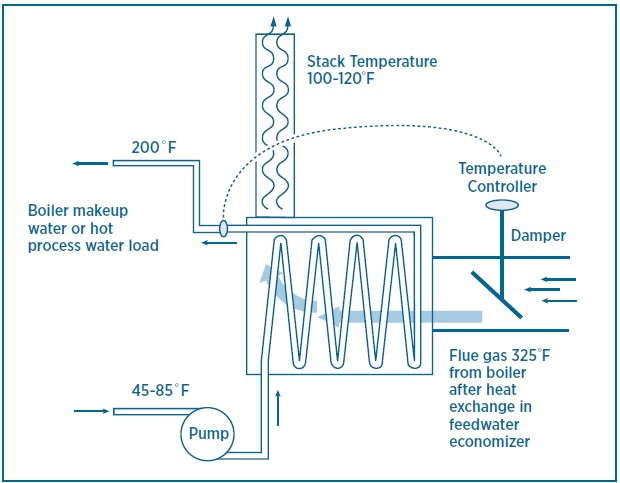

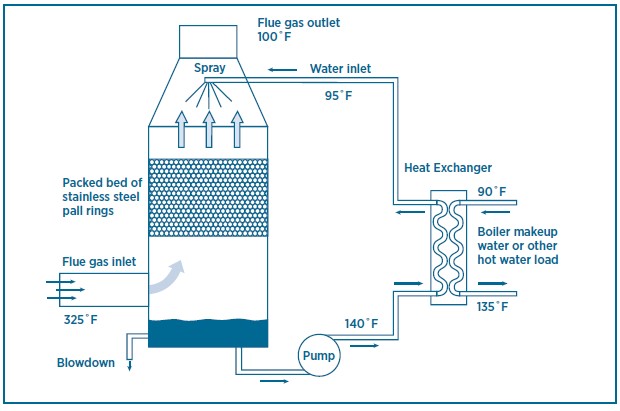

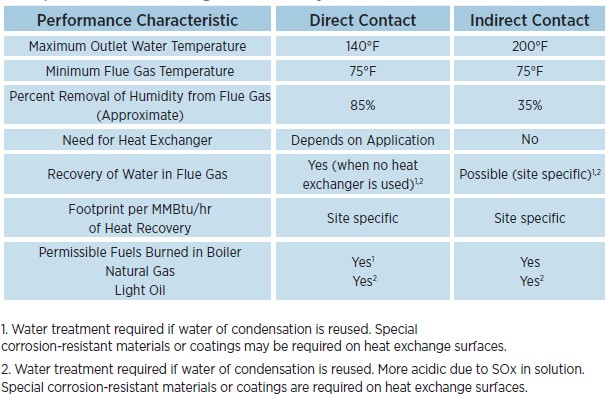

Economizers. In many boilers, the flue gases still have useful amounts of energy even after they have passed through the boiler. In many of these applications, economizers provide effective methods of increasing boiler efficiency by transferring the heat of the flue gases to incoming feedwater. There are two principal types of economizers: noncondensing and condensing. Non-condensing economizers are usually air-to-water heat exchangers. Because these economizers are not designed to handle flue gas condensation, noncondensing economizers must be operated at temperatures that are reasonably above the dew points of the flue gas components. The dew point of the flue gases depends largely on the amount of water in the gas, which, in turn, is related to the amount of hydrogen in the fuel. For example, to avoid condensation in the exhaust gases produced by burning natural gas, the exhaust gas temperature should typically be kept above 250°F. Condensing economizers are designed to allow condensation of the exhaust gas components. Due to latent heat recovery, these economizers typically extract more energy than do noncondensing economizers and are used in several industries. Often, special materials are required, such as specialty stainless steels.

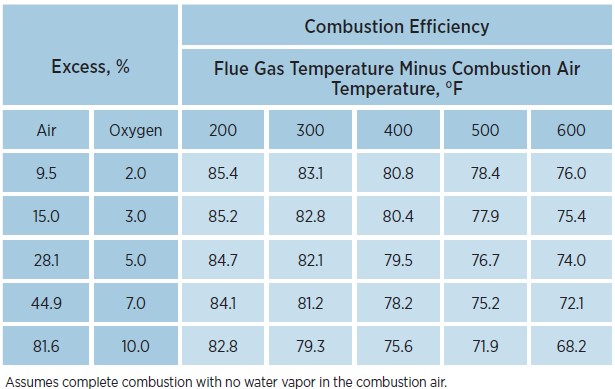

Combustion air preheaters. Combustion air preheaters are similar to economizers in that they transfer energy from the flue gases back into the system. In these devices, however, the energy is transferred to the incoming combustion air. The efficiency benefit is roughly 1% for every 40°F increase in the combustion air temperature.6

Boiler Insulation

The walls and combustion regions of boilers are typically lined with insulating materials to reduce energy loss and to prevent leakage. There are several types of boiler insulating materials, including brick, refractory, insulation, and lagging. The selection and design of boiler insulating materials depends largely on the age and design of the boiler. Since the insulating lining is exposed to high temperatures and is subject to degradation, it should be periodically inspected and repaired when necessary. New materials technologies allow efficient insulation in tight spaces previously impossible to insulate.

Boiler Control System

Boiler control systems are designed to protect the boiler and to ensure proper boiler operation. These systems include the combustion control system, flame safeguard, water level control, and fuel control.

Combustion control system. The combustion control system regulates the fuel and air mixture to achieve safe and efficient combustion and maintains proper steam system pressure. Control systems have varying levels of sophistication. Simple systems use a fixed linkage between the fuel-regulating valve and the combustion air damper. This is called single point positioning. A change in steam pressure makes a proportional change in the combustion air and fuel. Modern systems rely on signals from digital transmitters to determine independent fuel valve and air damper positions, and it typically provides alarms for out-of-specification conditions for investigation and remedy. This is called a full monitoring system.

Burner flame safeguard system. A flame safeguard system is an arrangement of flame detection systems, interlocks, and relays which will sense the presence of a proper flame in a furnace and cause fuel to be shut off if a hazardous condition develops. Modern combustion sys-tems are closely interlocked with flame safeguard systems and also pressure-limit switches, low-water level cutoffs, and other safety controls that will stop the energy input to a boiler when an unsafe condition develops. The flame safeguard system senses the presence of a good flame or proper combustion and programs the operation of a burner system so that motors, blowers, ignition, and fuel valves are energized only when they are needed and then in proper sequence.

Safety shut-off valve. Safety shut-off valves isolate the fuel supply to the boiler in response to certain conditions such as low or high gas pressure or satisfied load demand. The type of safety shutoff valves and the settings are often determined by code or insurance requirements.

Water-level control. The boiler water-level control system ensures a safe water level in the boiler. Typically, the control system provides a signal to the feedwater control valve to regulate the feed rate. Simple water-level control systems that only sense water level are single-element systems. More complex systems incorporate additional data such as steam flow rate (dual-element system) and feedwater flow (triple-element system) and will provide better water level control during abrupt load changes.

Safety valve. The safety valve is the most important valve on the boiler and keeps the boiler from exceeding its maximum allowable working pressure (MAWP).

Steam-pressure control. Steam-pressure controls regulate the combustion equipment to maintain a constant pressure in the steam header. As the pressure rises above or falls below the pressure setting, the control adjusts the burner firing rate to bring the pressure back to the setpoint.

Nonreturn valve. The nonreturn valve is a combination shutoff and check valve that allows steam out of the boiler, but prevents backflow from the steam header in the event the boiler pressure drops below that of the header. The valve is opened only when the pressure inside the boiler rises slightly above the steam header pressure.

Steam flow meter. Steam flow meters are helpful in evaluating the performance of the system and can provide useful data in assessing boiler performance, calculating boiler efficiency, and tracking the amount of steam required by the system. In some systems, steam flow meters provide a measurement signal for the boiler control system. Additionally, steam flow meters can be useful in benchmarking efforts.

There are three basic types of steam flow meters: differential pressure (DP), vortex, and Coriolis. Differential pressure flow meters rely on the change in pressure as steam flows by an element such as a nozzle, orifice, or venturi. This pressure difference provides an indication of flow velocity, which, in turn, can be used to determine the flow rate. Vortex flowmeters rely on the principal that flow past an element creates vortices that have frequencies that correspond to the flow velocity. Coriolis flowmeters rely on tubes placed in the steam flow path that twist according to the velocity of the flow.

Boiler Feedwater System

The boiler feedwater system supplies water to the boiler. Sources of feedwater include returning condensate and makeup water. Feedwater is typically stored in a collect-ing tank to ensure that a steady supply of heated water is available to the boiler regardless of momentary fluctuations in availability of condensate return or fresh water supply pressure.

Feedwater flow control valve. A modulating feedwater flow control valve moves up or down in response to the water level transmitter(s). On smaller firetube boilers, it is not uncommon for the feedwater valve to operate in a closed or open position, depending on the water level transmitter signal. In modern industrial boilers, the con-trols may also account for significant variations in steam demand.

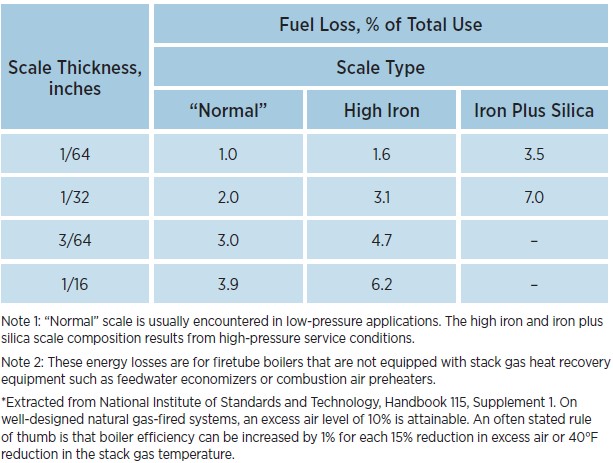

Softener. Softeners remove hardness minerals, such as calcium, magnesium, and iron, from a water supply. The presence of hardness in boiler water leads to many problems, including scale buildup and foaming, which reduce boiler efficiency and can cause tube failure. Softeners reduce this problem through an ion exchange process. As the hard water passes through a chamber filled with resin, an exchange occurs that removes hardness minerals from the water. The sodium that replaces the hardness minerals has a higher solubility in water and generally will not form scale.

Pretreatment equipment. Pretreatment equipment improves the quality of the incoming water so that it may be used in the boiler without excessive scaling or foaming, which can reduce boiler efficiency and cause tube failure. Pretreatment equipment includes, but is not limited to, clarifiers, filters, softeners, dealkalizers, decarbonators, reverse osmosis (RO) units, and demineralizers.

Deaerator, deaerating heater, and atmospheric deaerator. The presence of oxygen in the boiler system can be a significant problem because of its corrosivity at high temperatures. Deaerators and deaerating heaters use heat, typically steam, to reduce the oxygen content in water. Deaerators and deaerating heaters are typically pressurized tanks that raise the water temperature to the point of saturation. They also break the incoming water into either fine droplets or thin sheets to facilitate the removal of oxygen and other noncondensable gases. Depending on the design, the feedwater oxygen content can be reduced to levels ranging from 7 to 40 parts per billion (ppb).

Atmospheric deaerators are typically found in smaller, lower-pressure boiler systems. They operate at atmospheric pressure, so the maximum operating temperature is 212°F. Most will operate at temperatures lower than this. Atmospheric deaerators cannot achieve the same level of oxygen removal as deaerators and deaerating heaters, typically providing water with oxygen levels of 0.5 to 1 part per million (ppm).

In applications that require lower oxygen levels than achievable with a deaerator, deaerating heater, or open feedwater heater, a chemical agent, known as an oxygen scavenger, can be used to remove more oxygen. In most systems, an oxygen scavenger is part of the system’s water treatment program.

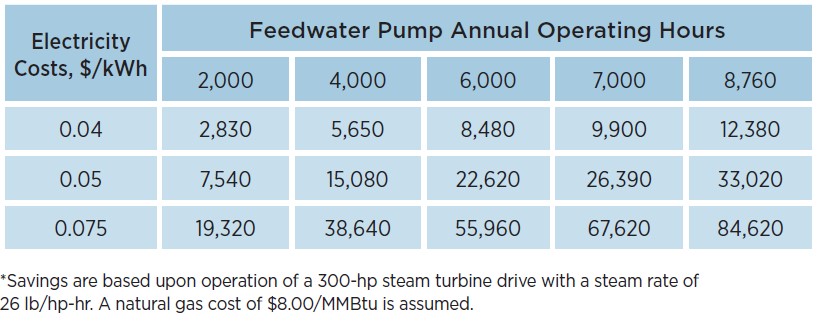

Feedwater pump. Feedwater pumps transfer water from the deaerator to the boiler. Feedwater pumps are driven by electric motors or by steam turbines. In a modulating feedwater system, the feedwater pumps run constantly as opposed to an on/off operation in relatively small boilers.

Collecting/Storage tank. The return of condensate is often erratic due to changing steam requirements by the end uses. The condensate is usually returned to a condensate receiver or directly to the deaerator if the system does not have a receiver. Pretreated water may also be stored in a tank prior to use. This provides the boiler system with additional water capacity in case the pretreatment equipment malfunctions. The condensate and pretreated water, or makeup, are transferred from the storage tanks to the deaerator before being sent to the boiler.

Boiler Combustion Air System

The combustion air system supplies the oxygen necessary for the combustion reaction. To provide enough air for the amount of fuel used in industrial boilers, fans are typically required. Dampers, inlet valves, or variable speed drives typically control the amount of air allowed into the boiler.

Forced draft fan. A forced draft fan is located at the inlet of a boiler and pushes ambient air into the burner region, ensuring that adequate air is delivered to the combustion process. These fans either pull air directly from the boiler room or connect to a duct system that allows outside air to be drawn into the boiler.

Induced draft fan. Induced draft fans are located on the outlet gas side of the boiler and pull flue gases out. The induced draft fan creates a slightly negative furnace pressure that is controlled by outlet dampers on the boiler. In some systems where a bag house, mechanical collector, or precipitator is involved, special considerations should be given in sizing and selection of this fan.

Damper. Dampers control the amount of air allowed into and out of a combustion chamber. Dampers, in combination with fuel regulating devices, are positioned by the combustion control system to achieve certain fuel-to-air ratios. Dampers on the boiler outlet are used to regulate the negative furnace draft.

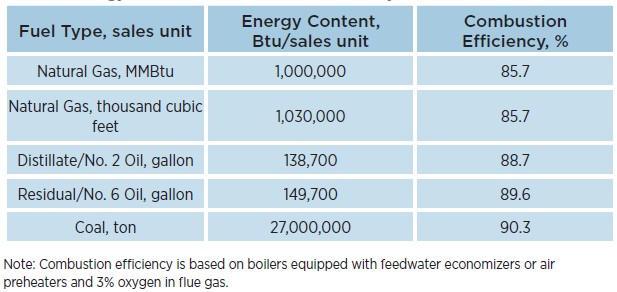

Boiler Fuel System

There are many different types of fuels used in boilers, requiring several different types of fuel handling systems. Biomass fuels provide emission options that are carbon neutral. Fossil fuels such as coal, oil, and gas are most commonly used. Waste fuels are used in many industries, particularly the forest products, petroleum refining, and chemical manufacturing industries where there is an avail-able supply of waste products such as bark, wood chips, black liquor, and refinery gas.

Fuel regulating valve. In gaseous and liquid fuels, regulating valves control the fuel delivered to the boiler. In many systems, these valves can be quickly shut in response to an operating problem.

Fuel. The fuel types that are commonly used in boilers include natural gas, coal, propane, fuel oils, and waste fuels (for example, black liquor, bark, and refinery gas). Fuel type significantly affects boiler operation, including efficiency, emissions, and operating cost. In 2005, almost 78% of boiler units and 56% of industrial boiler capacity were identified as natural gas-fired. Some industries use by-product fuel in a large portion of their boiler capacity, including paper (48%), refining (49%), and primary metals (42%). Coal, oil, and wood are important fuels in certain industries and regions, but fuel a small fraction of the boiler capacity on a national basis. More detail is available in the reference below.

Fuel flow meter. Fuel meters measure the amount of fuel delivered to a boiler. Fuel meters provide essential data in determining boiler efficiency. Since fuel flow meters measure volume or mass of fuel, it is important to know the energy content of the fuel when determining boiler efficiency.

Burner. Burners combine the fuel and air to initiate combustion. There are many different types of burners due to the many different types of fuels. Additionally, burners have different performance characteristics and control requirements. Some burners are on/off, while others allow precise setting of the fuel:air mixture over a range of conditions. Some burners can fire different types of fuel, allowing boiler operation to continue despite the loss of one fuel supply.

Boiler Blowdown System

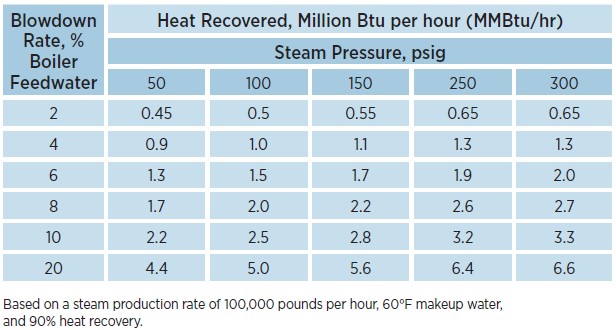

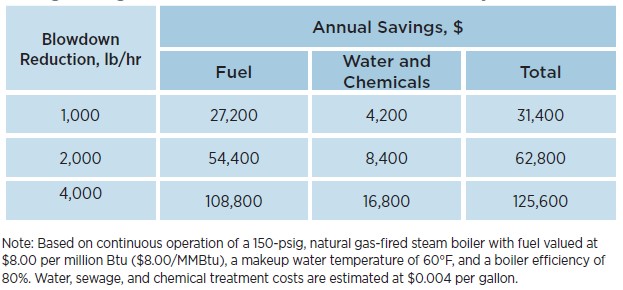

The boiler blowdown system includes the valves and the controls for the continuous blowdown and bottom blow-down services. Continuous blowdown removes a specific amount of boiler water (often measured in terms of percentage of feedwater flow) in order to maintain a desired level of total dissolved solids in the boiler. Setting the flow for the continuous blowdown is typically done in conjunction with the water treatment program. Some continuous blowdown systems rely on the input of sensors that detect the level of dissolved solids in the boiler water.

The bottom blowdown is performed to remove particulates and sludge from the bottom of the boiler. Bottom blow-downs are periodic and are typically performed a certain number of times per shift or according to a set schedule. In some systems, bottom blowdowns are controlled by an automatic timer. Bottom blowdown should never be permitted unless it is recommended by the boiler manufacturer. This is because in higher pressure boilers, especially those above 700 pounds psig, bottom blowdown may cause water starvation in some portions of the boiler circuit.

Boiler blowdown heat exchangers and flash tank. The continuous blowdown water has the same temperature and pressure as the boiler water. Before this high energy water is discharged into the environment, it is often sent to a heat exchanger and flash tank. Flash tanks permit the recovery of low-pressure flash steam, which can be used in deaeration or process heating. They also permit the use of a smaller heat exchanger than would be required without the flash tank. Blowdown heat exchangers are most often used to preheat boiler makeup water.

Performance Improvement Opportunities

Overview

Several important factors should be considered when industrial facilities seek to improve steam system per-formance and to lower operating costs. Improving steam system performance requires assessing the entire system, identifying opportunities, and selecting and implementing the most feasible projects. In turn, this requires a systems approach. Similarly, proper selection of the best projects requires quantifying the benefits and costs of each project. Successful implementation of these projects requires the participation of all system stakeholders including produc-tion, maintenance, and management. Generally, obtaining management participation requires communication of the analyses in economic terms. To address these consider-ations, this section of the course discusses:

- The systems approach

- Common performance improvement opportunities

- Resources that can help identify and assess opportunities

- The economics related to steam system improvements.

Energy Efficiency Statistics

The latest statistics for energy efficiency participation can be found at www.eia.gov in the Manufacturing Energy Consumption data, Consumption and Efficiency section under the Sources & Uses tab.

Systems Approach

Because of the many industrial uses for steam, there are wide ranges of steam system sizes, configurations, end-use applications, and operating practices. As a result, there are many different ways to improve steam system performance and identify improvement opportunities. In general, performance is most effectively optimized when a systems approach is used.

A systems approach analyzes both the supply and demand sides of the system and how they interact, essentially shifting the focus from individual components to total system performance. Often, operators are so focused on the immediate demands of the equipment that they overlook the broader issue of how system parameters affect the equipment. Similarly, a common engineering approach is to break a system down into its basic components or modules, optimize the selection or the design of these components, and then assemble these components to form the system. An advantage to this approach is that it simplifies problems. However, a disadvantage is that it often over-looks the interaction of these components. In contrast, a systems approach evaluates the entire system to determine how the end-use requirements can be most effectively and efficiently served.

A systems approach also recognizes that system efficiency, reliability, and performance are closely related. For example, an efficiency loss such as heat loss across uninsulated pipe surfaces reduces energy available to the end uses and requires boilers to work harder to meet a given demand. Often, energy losses create additional system stresses that accelerate wear and that can create loads for which the system was not originally designed.

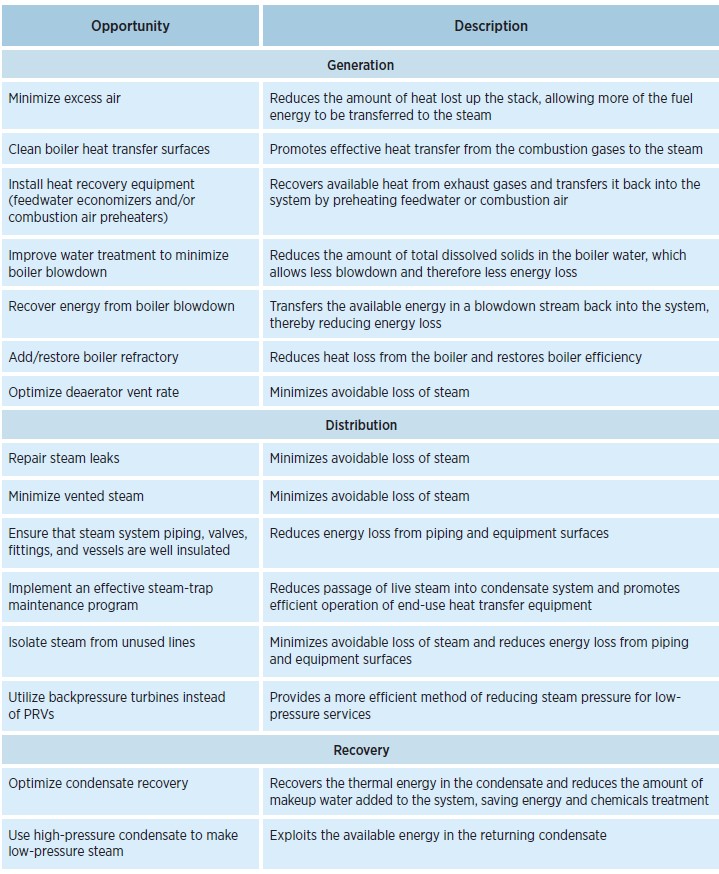

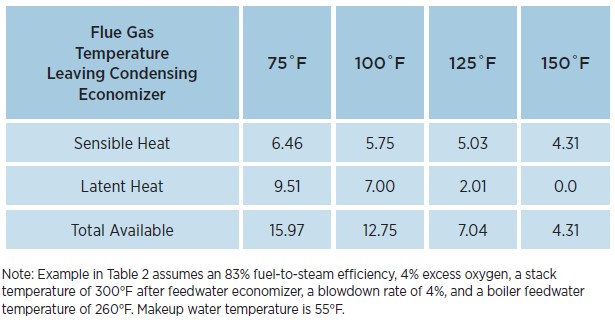

Common performance improvement opportunities for the generation, distribution, and recovery areas of a steam system are listed in Table 2.

Strategic, Performance Improvement Opportunities—Management-Based Systems

Systems, Standards, and Certification

AMO works with U.S. industry to support the development of energy management standards and a related certification program anchored to a viable business case. Similar to environmental or quality management systems, changing how energy is managed has resulted in substantial energy performance improvements.

Visit www.eere.energy.gov/energymanagement/ to learn how the various standards are related, as well as information on a web-based toolkit that organizations can use to implement an energy management system consistent with ISO 50001 standards and other existing management standards.

Management Standard – ISO 50001—Plant-Level Energy Management

The energy management standard, ISO 50001, provides a method for integrating continuous improvement in energy efficiency into existing management systems. ISO 50001 creates a framework for organizations to manage energy and improve profitability. The forthcoming industry-designed American National Standards Institute (ANSI)-accredited plant-certification program—known as Superior Energy Performance—will include provisions for conforming to the ISO 50001 energy management standard, as well as achieving annual certification by reaching a defined level of annual, energy-intensity performance improvement.

Superior Energy Performance

Superior Energy Performance (SEP) facilities continuously manage their energy consumption, reduce energy intensity, and validate savings using qualified, independent, measurement and verification entities.

Visit www.superiorenergyperformance.net for details.

Proven Results. Several facilities have piloted the approach in demonstration projects prior to the launch of Superior Energy Performance. These facilities demonstrated impressive results that are nearly twice the efficiency gains of business as usual. SEP has piloted four Texas plants: Cook Composites and Polymers (Houston); Freescale Semiconductor, Inc. (Oak Hill); Owens Corning (Waxahachie); and Union Carbide, a subsidiary of Dow Chemical Company (Texas City). The pilot sites provided substantial input into the design of the program, as did other end users on the U.S. Council for Energy-Efficient Manufacturing. The four pilot sites saw verified energy performance improvements from 6.5% to more than 15% over a 2- to 3-year period.

Four pilot sites verified energy performance improvements from 6.5% to more than 15% in a 2- to 3-year period.

Certification: Documenting Results. A central element of SEP is implementation of the ISO 50001 standard, with additional requirements to achieve and document energy intensity improvements. SEP is designed to encourage participation among facilities of all sizes and all levels of experience in managing energy. The program offers flexibility depending on the degree of data validation desired by an organization or facility. Verification bodies will undertake verification for the SEP program and will be accredited by ANSI. A series of complementary professional credentialing programs train and qualify professionals to assist and audit facilities.

Third-party validation of continuous improvement should be beneficial to organizations in many ways, including improving the chances of securing financing for energy efficiency projects.

Supporting Standards for Steam Assessments. The Association for Mechanical Engineers (ASME) provides a standard that supports industrial steam assessment protocols.

ASME Sidebar PART 1 of 3

The Standard ASME EA-3 – 2009, Energy Assessment for Steam Systems contains detailed sections, including:

Table of Contents

- – Scope and Introduction

- – Definitions

- – References

- – Organizing the Assessment 5 – Conducting the Assessment 6 – Assessment Data Analysis

- – Report and Documentation

ASME Sidebar PART 2 of 3

Abstracted portions from several sections follow:

“4.2 Facility Management Support – Facility management support is essential for the successful outcome of the assessment. Facility management shall understand and support the purpose of the assessment. …”

“5.1 Overall Assessment Method – The overall method to be used in assessing the steam system is a sequential screening process as shown in Fig. 1. This investigation process shall evaluate the operating characteristics of the individual components, subsystems, processes, and the system as a whole …”

“5.4 Target Areas for Assessment – An assessment includes evaluation of the steam sources …, distribution, end use, and condensate recovery. Assessment activities shall focus on quantification of energy losses and the identification …”