Introduction

Laboratory testing of soils and rocks is a fundamental element of geotechnical engineering. The complexity of testing required for a particular project may range from a simple moisture content determination to sophisticated triaxial strength testing. A laboratory test program should be well-planned to optimize the test data for design and construction. The geotechnical specialist, therefore, should recognize the projects issues ahead of time so as to optimize the testing program, particularly strength and consolidation testing.

Laboratory testing of samples recovered during subsurface investigations is the most common technique to obtain values of the engineering properties necessary for design. A laboratory-testing program consists of “index tests” to obtain general information on categorizing materials, and “performance tests” to measure specific properties that characterize soil behavior for design and constructability assessments (e.g., shear strength, compressibility, hydraulic conductivity, etc.). This course provides information on common laboratory test methods for soils and rocks including testing equipment, general procedures related to each test, and parameters measured by the tests.

1.1 Quality Assurance for Laboratory Testing

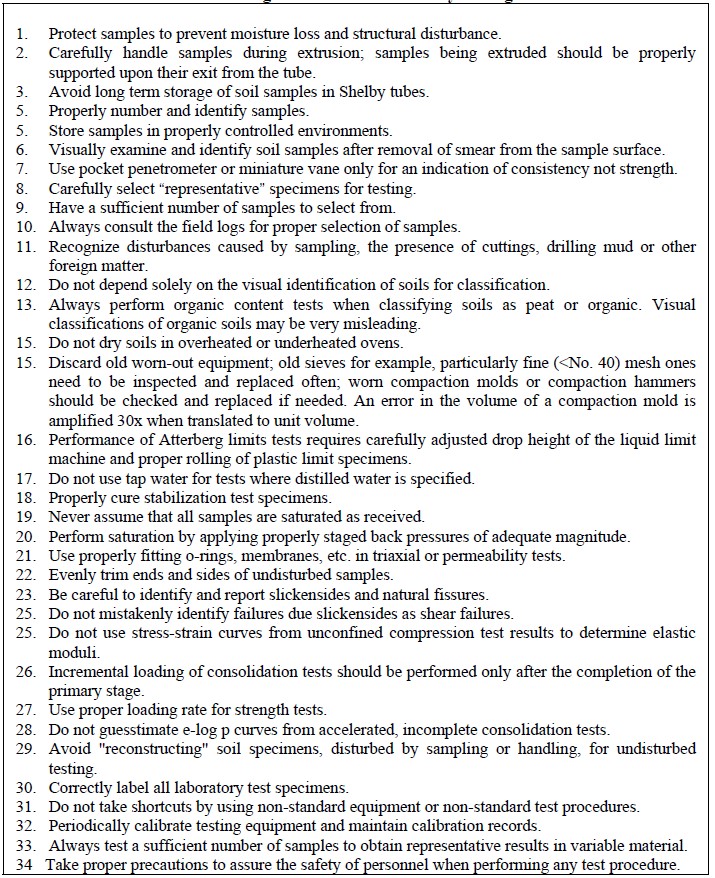

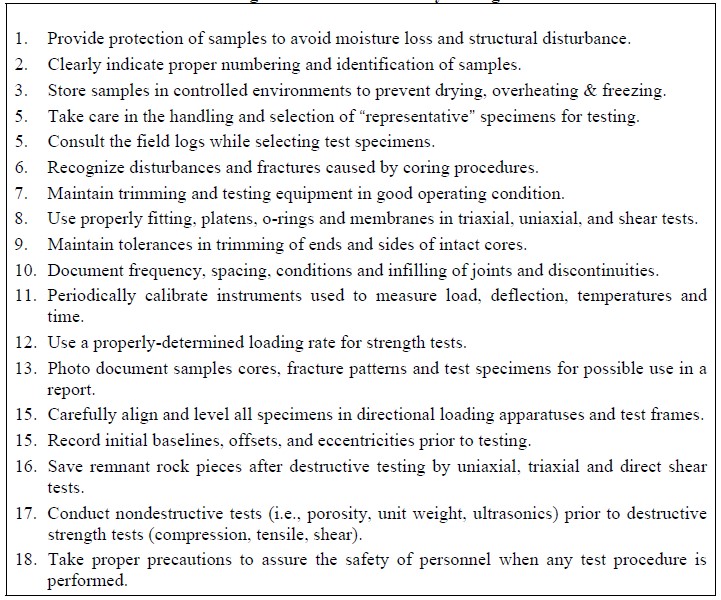

Laboratory testing will be required for most projects. Therefore, it is necessary to select the appropriate types and quantities of laboratory tests to be performed. A careful review of all data obtained during the field investigation and a thorough understanding of the preliminary design of geotechnical, structural and hydraulic features of the project are essential to develop an appropriately scoped laboratory testing program. In some cases owners may hire external testing laboratories to perform select tests. It is necessary that testing requests be clear and sufficiently detailed. Unless specialized testing is required, the owner should require that all testing be performed in accordance with the appropriate specifications for laboratory testing such as those codified in AASHTO and/or ASTM. Several tables are presented in this course that summarize various common tests for soils and rocks per AASHTO and ASTM standards. In order to assure that the results of laboratory testing are representative, several precautions must be taken before the tests themselves are performed. These precautions include: sample tracking, sample storage, sample handling to prevent sample disturbance, and sample selection. Discussion of each of these precautions follows.

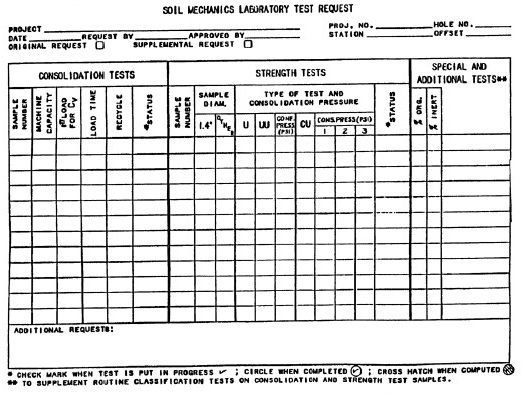

1.1.1 Sample Tracking

Whether the laboratory testing is performed in-house or is subcontracted, samples will likely be assigned a laboratory identification number that differs from the identification number assigned in the field. A list should be prepared to match the laboratory identification number with the field identification number. This list can also be used to provide tracking information to ensure that each sample arrived at the lab. When laboratory testing is requested, both the field identification number and the laboratory identification number should be used on the request form. An example request form is shown in Figure 1-1. A spreadsheet or database program is useful to manage sample identification data.

1.1.2 Sample Storage

Undisturbed soil samples should be transported and stored so that that the moisture content is maintained as close as possible to the natural conditions (AASHTO T 207, ASTM D 4220 and D 5079). Samples should not be placed, even temporarily, in direct sunlight. Shelby tubes should be stored in an upright position with the top side of the sample up in a humid room with relative humidity above 90%.

Long-term storage of soil samples in Shelby tubes is not recommended. As storage time increases, moisture will migrate within the tube. Potential for disturbance and moisture migration within the sample will increase with time, and samples tested 30 days after their retrieval should be noted on the laboratory data sheet. Excessive storage time can lead to additional sample disturbance that will affect strength and compressibility properties. Additionally, stress relaxation, temperature changes, and storage in a room with humidity below 90 percent may have detrimental effects on the samples. Long-term storage of soil samples should be in temperature- and humidity-controlled environments. The temperature control requirements may vary from sub freezing to ambient and above, depending on the environment of the parent formation. The relative humidity for soil storage normally should be maintained at 90 percent or higher to prevent moisture evaporation from the samples.

Long-term storage of soil samples in Shelby tubes is not recommended for another reason. During long term storage the sample tubes may corrode. Corrosion accompanied by adhesion of the soil to the tube may result in the development of such a large sidewall resistance that some soils may experience internal failures during extrusion. Often these failures cannot be seen by the naked eye; x-ray radiography (ASTM D 4452) will likely be necessary to confirm the presence of such conditions. If these samples are tested as “undisturbed” specimens, the results may be misleading.

1.1.3 Sample Handling

Careless handling of nominally undisturbed soil samples after they have been retrieved may cause major disturbances that could influence test results and lead to serious design and construction consequences. Samples should always be handled by experienced personnel in a manner that ensures that the sample maintains structural integrity and its natural moisture condition. Saws and knives used to prepare soil specimens should be clean and sharp. Preparation time should be kept to a minimum, especially where the maintenance of the moisture content is critical. Specimens should not be exposed to direct sun, freezing, or precipitation.

1.1.4 Effects of Sample Disturbance

As a soil sample is removed from the ground during a conventional soil investigation, its in-situ effective stress condition is being changed. In addition, nominally undisturbed specimens taken from samples obtained from drilled boreholes will become disturbed as a result of the drilling itself, sampling, sample extrusion, and sample trimming to form a specimen for testing. These processes will also change the effective stress condition in the soil sample, i.e., the effective stress in the soil at the time after a sample is trimmed and prepared for testing is different from that of the same soil in the ground. Therefore the utmost care should be taken to minimize the effect of these processes in order for the results of laboratory tests to represent the in-situ soil behavior accurately.

1.1.5 Specimen Selection

The selection of representative specimens for testing is one of the most important aspects of sampling and testing procedures. Selected specimens must be representative of the formation or deposit being investigated. The geotechnical specialist should study the boring logs, understand the geology of the site, and visually examine the samples before selecting the test specimens. Samples should be selected on the basis of their color, physical appearance, structural features and an understanding of the disturbance of the samples. Specimens should be selected to represent all types of materials present at the site, not just the worst or the best.

Samples with discontinuities and intrusions may fail prematurely in the laboratory. The first inclination would be to test these samples. However, if these features are small and randomly located, they may not necessarily cause such failures in the field. Therefore samples having such local features should be noted, but not necessarily selected for testing since such samples may not be representative of the stratum in terms of its response to applied loads.

Certain considerations regarding laboratory testing, such as when, how much, and what type, can be decided only by an experienced geotechnical specialist. The following minimal criteria should be considered when the scope of the laboratory testing program is being determined:

- Project type (bridge, embankment, building, reconstruction or new construction, etc.)

- Size of the project (geographic extent).

- Loads to be imposed on the foundation soils (geometry, type, direction and magnitude).

- Performance requirements for the project (e.g., settlement and lateral deformation limitations).

- Vertical and horizontal variations in the subsurface profile as determined from boring logs and visual identification of subsurface material types in the laboratory.

- Known or suspected peculiarities of subsurface strata at the project location (e.g.,swelling soils, collapsible soils, organics, etc.)

- Presence of visually observed intrusions, slickensides, fissures, concretions, etc.

The selection of tests should be considered preliminary until the geotechnical specialist is satisfied that the test results are sufficient to develop reliable subsurface profiles and provide the parameters needed for design.

1.2 Laboratory Testing for Soils

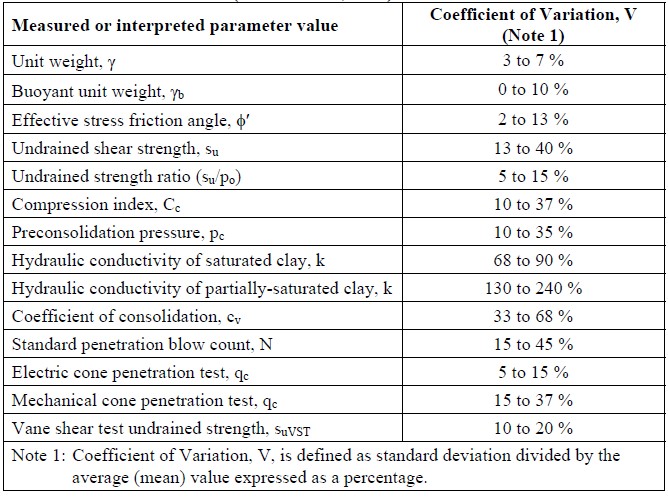

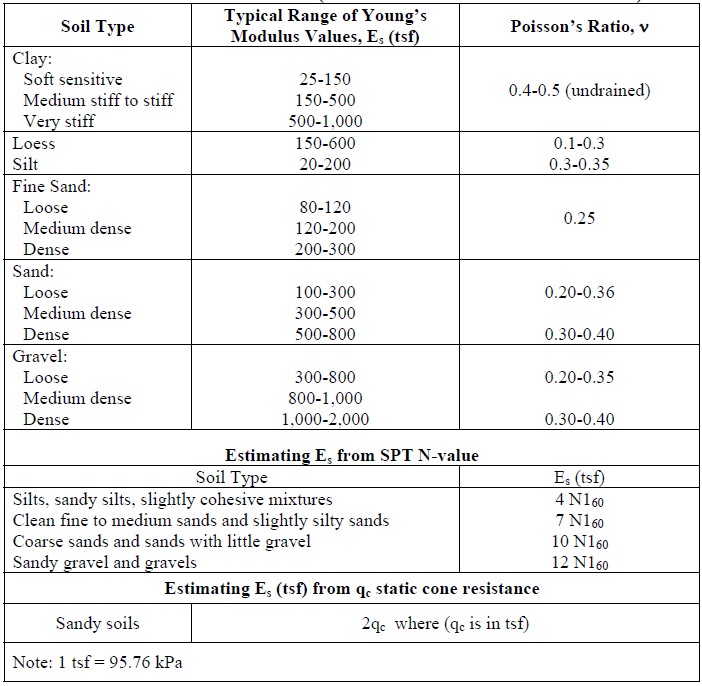

Table 1-1 provides a listing of commonly-performed soil laboratory tests. Tables 1-2 and 1-3 provide a summary of typical soil index and performance tests, respectively. Additional information on these tests is provided in subsequent sections.

1.3 Laboratory Index Tests for Soils

1.3.1 General

Data generated from laboratory index tests provide an inexpensive way to assess soil consistency and variability among samples collected from a site. Information obtained from index tests is used to select samples for engineering property testing as well as to provide an indicator of general engineering behavior. For example, a soil with a high plasticity index (PI) can be expected to have high compressibility, low hydraulic conductivity, and high swell potential. Common index tests discussed in this course include moisture content, unit weight (wet density), Atterberg limits, particle size distribution, visual classification, specific gravity, and organic content. Index testing should be conducted on each type of soil material on every project. Information from index tests should be assessed prior to a final decision regarding the specimens selected for subsequent performance testing.

1.3.2 Moisture Content

The moisture (or water) content test is one of the simplest and least expensive laboratory tests to perform. Moisture content is defined as the ratio of the weight of the water in a soil specimen to the dry weight of the specimen. Natural moisture contents (wn) of sands are typically 0 ≤ wn ≤ 20 %, whereas for inorganic and insensitive silts and clays, the typical range is 10 ≤ wn ≤ 40 %. However, for clays it is possible to have more water than solids (i.e., wn > 100%), depending upon the mineralogy, formation environment, and structure of the clay. Therefore, soft and highly compressible clays, as well as sensitive, quick, or organically rich clays, can exhibit water contents in the range of 40 ≤ wn ≤ 300 % or more.

Moisture content can be tested a number of different ways including: (1) a drying oven (ASTM D 2216); (2) a microwave oven (ASTM D 4643); or (3) a field stove or blowtorch (ASTM D 4959). While the microwave or field stove (or blowtorch) methods provide a rapid evaluation of moisture content, potential errors inherent with these methods require confirmation of results obtained by using ASTM D 2216. The radiation heating induced by the microwave oven and the excessive temperature induced by the field stove may release water entrapped in the soil structure (adsorbed water) that would normally not be released at 230o F (110o C), the maximum temperature specified by ASTM D 2216. Therefore, the microwave oven and field stove methods may yield greater values of moisture content than would occur from ASTM D 2216. Field measurements of moisture content often rely on a field stove or microwave due to the speed of testing. For control of compacted material, it is common to use a nuclear gauge (ASTM D 3017) in the field to assess moisture contents rapidly. Nuclear gage readings may indicate widely varying moisture contents for micaceous soils, i.e., soils containing a significant amount of mica particles. Results from nuclear techniques should be “calibrated” or confirmed by using the drying oven method (ASTM D 2216).

Moisture contents of soils as determined from in-situ moisture content tests may be altered during sampling, sample handling, and sample storage. Because the top end of the sample tube may contain water or collapse material from the borehole, moisture content tests should not be performed on material near the top of the tube. Also, as storage time increases, moisture will migrate within a specimen and lead to altered values of moisture content. If the sample is not properly sealed, moisture loss through drying of the sample will likely occur.

1.3.3 Unit Weight

The terms density (ρ) and unit weight (γ) are often incorrectly used interchangeably. The correct usage is that density implies mass while unit weight implies weight measurements. Density and unit weight are related through the gravitational constant (g) as follows: γ = ρg. In this document they will be referenced as “density (unit weight)” if the usage is independent of the specific definition.

In the laboratory, soil unit weight and mass density are easily measured on tube (undisturbed) samples of natural soils. The moist (total) mass density is ρt = Mt/Vt, where Mt is the total mass of the soil sample including the mass of the moisture in the pores and Vt is the total volume of the soil sample. Similarly the dry mass density is given by ρd = Ms/Vt , where Ms is the mass of the solid component of the soil sample and Vt is the total volume of the soil sample. Likewise, the moist unit weight is γt = Wt/Vt, where Wt is the total weight including the weight of the water in the pores and Vt is the total volume of the soil sample. Similarly, the dry unit weight is defined as γd = Ws/Vt where Ws is the weight of the solid component of the soil sample and Vt is the total volume of the soil sample. The relationship between the total and dry mass density and unit weight in terms of natural moisture content, w, is given by:

Since γ = ρg the relationship between total and dry unit weight is given by:

Field measurements of soil mass density (unit weight) are generally restricted to shallow surface samples such as those obtained during placement of compacted fills. In those cases, field measurements of soil mass density (unit weight) can be accomplished by using drive tubes (ASTM D 2937), the sand cone method (ASTM D 1556), or a nuclear gauge (ASTM D 2922). To obtain unit weights or mass densities with depth, either high-quality thin-walled tube samples must be obtained (ASTM D 1587), or relatively expensive geophysical logging by gamma ray techniques (ASTM D 5195) can be employed.

Table 5-4 presents typical unit weights along with a range of void ratios for a variety of soils.

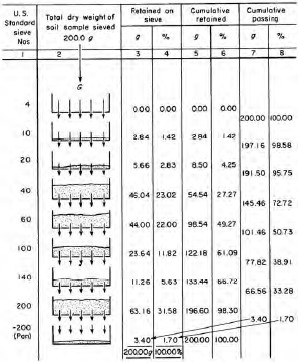

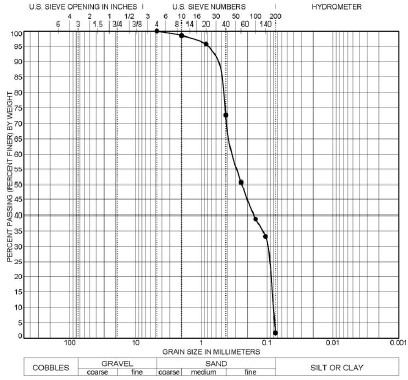

1.3.4 Particle Size Distribution

Particle size distributions by mechanical sieve and hydrometer analyses are useful for soil classification purposes. Procedures for grain size analyses are contained in ASTM D 422 and AASHTO T88. Testing is accomplished by shaking air-dried material through a stack of sieves having decreasing opening sizes. Each successive screen in the stack has a smaller opening to capture progressively smaller particles. The amount retained on each sieve is collected, dried and weighed to determine the percentage of material passing that sieve size. An example of how to determine the grain size distribution from sieve data is shown in Figure 1-2. The grain size distribution curve corresponding to the data in Figure 1-2 is presented in Figure 1-3.

Testing of the finer grained particles is accomplished by suspending the chemically dispersed particles in a water column and measuring the change in the specific gravity of the liquid as the particles fall from suspension. This part of the test is commonly referred to as a hydrometer analysis.

Obviously, obtaining a representative specimen is an important aspect of this test. When soil samples are dried or washed for testing, it may be necessary to break up the soil clods. Care should be taken to avoid crushing of soft carbonate or sand particles. If the soil contains a substantial amount of fibrous organic materials, these may tend to plug the sieve openings during washing. The material settling over the sieve during washing should be constantly stirred to avoid plugging.

Particle size testing is relatively straightforward, but the results can be misleading if procedures are not performed correctly and/or if equipment is not maintained in good working condition. If the sieve screen is distorted, large particles may be able to pass through sieve openings that typically would retain the particles. Material lodged within the sieve from previous tests could become dislodged during shaking, thereby increasing the weight of material retained on the following sieve. Therefore, sieves should be cleaned thoroughly after each test. A wire brush may distort finer sieve meshes during cleaning, so a plastic brush should be used to clean the U.S. No. 40 (0.425 mm) sieve and finer. Openings of fine mesh No. 200 sieve (0.075 mm)) are easily distorted as a result of normal handling and use. Therefore, fine-mesh sieves should be replaced often. A simple way to determine whether sieves should be replaced is to examine the stretch of the sieve fabric on its frame periodically. The fabric should remain taut; if it sags, it has been distorted and should be replaced. A common cause of serious errors is the use of “dirty” sieves. Some soil particles, because of their shape, size or adhesion characteristics, have a tendency to lodge in the sieve openings. This is especially true of the fine mesh sieves.

Representative samples of fine-grained soils (i.e., samples containing more than 50% of particles with diameter less than the U.S. No. 200 sieve size (075 mm ) should not be oven dried prior to testing because some particles may cement together leading to a calculated lower fines content from mechanical sieve analyses than is actually present. When fine-grained particles are a concern, the wash sieve method (ASTM D 1140) should be performed to assess the fines content.

If the clay-size content is an important parameter, hydrometer analyses should be performed even though the hydrometer test provides only approximate results due to oversimplified assumptions. However, the results can still be used as a general index of silt and clay-size content. Depending upon the chemical makeup of the fine grained particles, the traditional sodium hexametaphosphate solution used to disperse the clay-size particles may not provide adequate dispersion. If the clay-size particles are not dispersed, the hydrometer data leads to the interpretation of a lower than actual clay-size content. In some cases the concentration of the dispersing agent may need to be increased or a different dispersing agent may need to be used. If the sieve and hydrometer analyses are performed correctly, the gradation curve should be continuous over a range that includes all particle sizes.

1.3.4.1 Sand Equivalent

The sand equivalent test is a rapid test to show the relative proportions of fine dust or claylike materials in aggregate (or soils). A sample of aggregate passing the No. 4 sieve (4.75-mm) sieve and a small amount of flocculating solution are poured into a graduated cylinder and are agitated to loosen the claylike coatings from the sand particles. The sample is then irrigated with additional flocculation solution forcing the claylike material into suspension above the sand. After a prescribed sedimentation period, the height of flocculated clay and height of sand are determined. The sand equivalent is determined from the ratio of the height of the sand to height of the clay and expressed as a percentage. Cleaner aggregates will have higher sand equivalent values. For asphalt pavements, agencies often specify a minimum sand equivalent around 25 to 35 (Roberts, et al., 1996). Higher values are used in case of compacted structural fill which may support structures.

1.3.5 Atterberg Limits

The Atterberg limits of a fine grained soil represent the moisture content at which the physical state of the soil changes. The tests for the Atterberg limits are referred to as index tests because they serve as an indication of several physical properties of the soil, including strength, permeability, compressibility, and shrink/swell potential. These limits also provide a relative indication of the plasticity of the soil, where plasticity refers to the ability of a silt or clay to retain water without changing state from a semi-solid to a viscous liquid. In geotechnical engineering practice, the Atterberg limits generally refer to the liquid limit (LL), plastic limit (PL), and shrinkage limit (SL). In this course the definition is extended further in terms of quantifiable parameters that permit their measurements in the laboratory. These quantifiable definitions are as follows:

- Liquid Limit (LL) – This limit represents the moisture content at which any increase in moisture content will cause a plastic soil to behave as a viscous liquid. The LL is defined as the moisture content at which a standard groove cut in a remolded sample will close over a distance of ½-inch (13 mm) at 25 blows of the liquid limit device (Figure 1-4). The test is performed on material passing a US Standard No. 40 sieve(0.425 mm). During the test the material is brought to various moisture contents, usually by adding water. The plot of moisture contents vs. blows required to close the groove is called a “flow curve” and the value of the liquid limit moisture content is obtained from the flow curve at 25 blows.

- Plastic Limit (PL) – This limit represents the moisture content at which the transition between the plastic and semisolid state of a soil occurs. The PL is defined as the moisture content at which a thread of soil just crumbles when it is carefully rolled out by hand to a diameter of 1/8-inch (3 mm).

- Shrinkage Limit (SL) – This limit represents the moisture content corresponding to the change between the semisolid to solid state of the soil. The SL is also defined asthe moisture content at which any further reduction in moisture content will not result in a decrease in the volume of the soil.

Based on the above index values, there are two useful related indices, namely, the Plasticity Index (PI) and the Liquidity Index (LI), as follows:

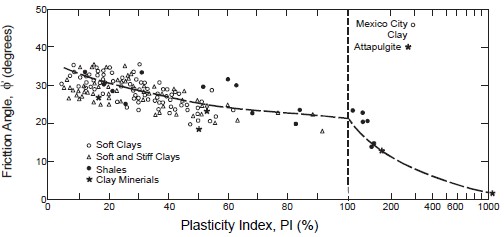

where w is the natural (in-situ) water content of the soil. Numerous engineering correlations have been developed that relate PI and LI to clay soil properties, including undrained and drained strength to PI and compression index to LI.

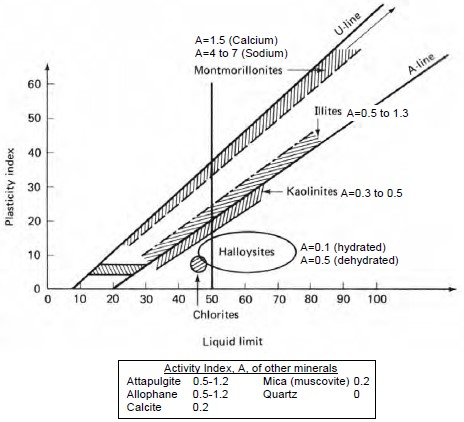

Another useful index proposed by Skempton (1953) based on the proportion of clay and PI is known as the “Activity Index.” The activity index of a clay soil is denoted by A and is generally defined as follows:

where CF is the clay fraction is usually taken as the percentage by weight of the soil with a particle size less than 0.002 mm. Clays with 0.75 < A < 1.25 are classified as “normal” clays while those with A < 0.75 are “inactive” and A > 1.25 are “active.” Values of activity index, A, can be correlated to the type of clay mineral that, in turn, provides important information relative to the expected behavior of a clay soil. A clay soil that consists predominantly of the clay mineral montmorillonite behaves very differently from a clay soil composed predominantly of kaolinite. Figure 1-5 also shows the activities of various clay minerals and their location on the Casagrande’s plasticity chart. The symbol for the activity index (A) in Figure 1-5 should not be confused with the “A-line” also shown in the figure.

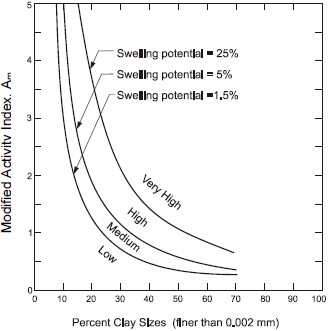

Modified Activity Index, Am: Based on their studies regarding the swell potential of compacted natural and artificial clay soils, Seed et al. (1962) proposed that for natural clay soils compacted as per the requirements of ASTM D 698 and Atterberg limits determined by ASTM D 4318 (AASHTO T 89, T 90), a Modified Activity Index, Am, defined as follows is more appropriate:

The above definition is used to define the swell potential of soils (see Section 1.7).

1.3.5.1 Significance of the “A-line” and “U-line” on Plasticity Chart

The equation for the A-line and U-line are:

The A-line generally separates soils whose behavior is more claylike (points plotting above the A-Line) from those that exhibit a behavior more characteristic of silt (points plotting below the A-line). The A-line also separates organic (below) from inorganic (above) soils. The LL = 50 line generally represents the dividing line between silt, clay and organic fractions of the soil that exhibit low plasticity (LL<50) and high plasticity (LL>50). The U-line shown in Figure 5-5 represents the upper range of PI and LL coordinates that have been found for soils. When the limits of any soil plot above the U-line, the results should be considered spurious and the tests should be rerun. Note that in Figure 5-5 the clay mineral montmorillonite plots well above the A-line and just below the U-line. If a soil plots in this range, it probably contains a significant amount of the clay mineral montmorillonite that expands in presence of water.

1.3.6 Specific Gravity

The specific gravity of solids (Gs) is a measure of solid particle density and is referenced to an equivalent volume of water. Specific gravity of solids is defined as Gs = (Ms/Vs)/ ρd where Ms is the mass of the soil solids and Vs is the volume of the soil solids and ρd is the mass density of water = 1,000 kg/m3 or 1 Mg/m3. This formulation represents the theoretically correct definition of specific gravity and can be rewritten as Gs = ρs / ρd.

However, since γ = ρg the gravitational constant appears in both the numerator and denominator of the expression and the equation for Gs can also be given as Gs = γs/γw where γs = unit weight of solid particles in the soil mass and γw = unit weight of water = 62.4 pcf (1,000 kg/m3 or 1 Mg/m3).

The typical values of specific gravity of most soils lie within the narrow range of Gs = 2.7 ± 0.1. Exceptions include soils with appreciable organics (e.g., peat), ores (e.g., mine tailings), or calcareous (high calcium carbonate content) constituents (e.g., caliche). It is common to assume a reasonable Gs value within the range listed above for preliminary calculations. Laboratory testing by AASHTO T100 or ASTM D 854 or D 5550 can be used to confirm the magnitude of Gs, particularly on projects where little previous experience exists and unusually low or high unit weights are measured.

1.3.7 Organic Content

A visual assessment of organic materials may be very misleading in terms of engineering analysis. Laboratory test method AASHTO T194 or ASTM D 2974 should be used to evaluate the percentage of organic material in a specimen where the presence of organic material is suspected based on field information or from previous experience at a site. The test involves weighing and heating a previously dried sample to a temperature of 824°F (440°C) and holding this temperature until no further change in weight occurs. At this temperature, the organics in the sample turn to ash and the sample is re-weighed. Therefore, with the assumption that the weight of the ash is negligible, the percentage of organic matter is the ratio of the difference in weight before and after heating the sample to 824°F (440°C) to the weight of the original dried sample. The sample used for the test can be a previously dried sample from a moisture content evaluation. Usually organic soils can be distinguished from inorganic soils by their characteristic odor and their dark gray to black color. In doubtful cases, the liquid limit should be determined for an oven-dried sample (i.e., dry preparation method) and for a sample that is not pre-dried before testing (i.e., wet preparation method). If drying decreases the value of the liquid limit by about 30 percent or more, the soil may usually be classified as organic (Terzaghi, et al., 1996).

Soils with relatively high organic contents have the ability to retain water. Water retention may result in higher moisture content, higher primary and secondary compressibility, and potentially higher corrosion potential. Organic soils may or may not be relatively weak depending on the nature of the organic material. Highly organic fibrous peats can exhibit high strengths despite having a very high compressibility. In some instances such soils may even exhibit tensile strength.

1.3.8 Electro Chemical Classification Tests

Electro chemical classification tests provide the geotechnical specialist with quantitative information related to the aggressiveness of the soil conditions with respect to corrosion and the potential for deterioration of typical foundation materials. Electro chemical tests include determination of pH, resistivity, sulfate ion content, sulfides, and chloride ion content. Depending on the application, limits of these electro chemical properties are established based on various factors such as corrosion rates for metals and disintegration rates for concrete. Tests to characterize the aggressiveness of a soil environment are important for design applications that include metallic elements, especially for ground anchors comprised of high strength steel and for metallic reinforcements in mechanically stabilized earth walls. ASTM and AASHTO test procedures are listed under “Corrosivity (Electrochemical)” in Table 1-1.

1.3.9 Laboratory Classification

In addition to field identification (ASTM D 2488), soils should be classified in the laboratory by using the Unified Soil Classification System (USCS) in accordance with ASTM D 2487 or by the AASHTO soil classification system in accordance with AASHTO T 145. The USCS will be used throughout the remainder of this document. Classification in the laboratory occurs in a controlled environment and more time can be spent on this classification than the identification exercise performed in the field. Laboratory and/or field identification is also important so that defects and features of the soil can be recorded that would not typically be noticed from index testing or standard classification. Some of the features include degree of calcium carbonate cementation, mica content, joints, and fractures.

1.4 Consolidation Testing

1.4.1 Process of Consolidation

Consolidation is a time-dependent decrease in the volume of a soil mass under applied loading. In highway design, static loading is represented by the permanent load placed on the soil by embankments and structures. Depending on the configuration of the load and the subsurface conditions, the stress increase due to the externally applied loads may extend below the water table where all the voids are filled with water. An applied load will cause the soil grains to readjust to a more compact position to carry the load. This readjustment cannot take place until the water, which is incompressible, escapes from the voids.

The rate of the readjustment of the soil particles is a function of the void size, which controls the rate at which the water can escape from the voids. The settlement associated with the readjustment of the soil particles due to migration of water out of the voids is known as primary consolidation.

The amount of primary consolidation will depend on the initial void ratio of the soil. The greater the initial void ratio, the more water that can be squeezed out, and the greater the primary consolidation. The rate at which primary consolidation occurs is dependent on the rate at which the water is squeezed out of the soil voids. Secondary compression occurs after primary consolidation is complete. Secondary compression occurs under constant load. It is caused by the soil particles reorienting or deforming under constant load at a very slow rate. This process is known as “creep” and it occurs in most soils when they are subjected to long-term applied loads. Therefore, secondary compression is also a time-dependent process. However, secondary compression is not dependent on water being squeezed out of the soil as is consolidation. That is why it is called “secondary compression” and not “secondary consolidation.” Primary consolidation accounts for the major portion of settlement in saturated fine-grained soils. Primary consolidation and secondary compression both contribute significantly to settlements in organic soil.

Some natural deposits of fine-grained soils experienced compression in geologic history due to the weight of glaciers, due to the weight of overlying soil that has been eroded, or due to desiccation. Since their void ratios were substantially reduced in the past by these processes, these soils are less compressible today. Such soils are called “preconsolidated” or “overconsolidated” since they have been subjected to greater stresses in the past than exist at present. This concept is important because overconsolidated soils can be reloaded such as by the load from an embankment or bridge substructure without settling appreciably until the currently applied load exceeds the preconsolidation load. Saturated fine-grained soil deposits, which have never consolidated under loads other than the current loads, are called “normally consolidated.” On the other end of the spectrum, soils whose present loading induces stresses in the soil that are greater than the maximum effective stress they have experienced in the past are called “under consolidated.” This means that the consolidation process under the existing loading is on-going and the soil will continue to consolidate until that process is complete, even if no additional loads are applied.

1.4.2 Consolidation Testing

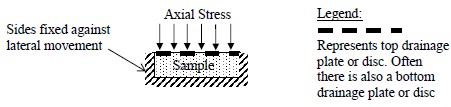

To predict the amount of consolidation in saturated fine-grained and organic soils, adequate testing must be performed. An undisturbed soil sample should be obtained in the field with a Shelby tube sampler. The oedometer or one-dimensional consolidometer is the primary laboratory equipment used to evaluate consolidation and settlement potential of fine-grained soils. A consolidation test is typically performed on a specimen obtained from an undisturbed sample retrieved from the deposit of fine-grained soils to evaluate the consolidation characteristics of the soil and define the settlement-time relationship of the in-situ soils under proposed foundation loads. The equipment for a consolidation test includes:

- A loading device that applies a vertical load to the soil specimen,

- A metal ring (fixed or free) that laterally confines the soil specimen and restricts deformation to the vertical direction only (i.e., only one-dimensional compression is modeled),

- Porous discs placed on the top and bottom of the sample to allow the sample to drain,

- A dial indicator or linear variable differential transducer (LVDT) to measure vertical displacement. Properly calibrated, each device should provide the same accuracy, but the electronic output of an LVDT can be incorporated into an automated recording system for quicker, more efficient, and higher resolution readings.

- A timer to assess the duration of loading increments. Monitoring of time for manual systems can be accommodated by use of a wall clock with a second hand. The internal clock of a computer is used for automated systems

- A surrounding container to permit the specimen to remain submerged during the test.

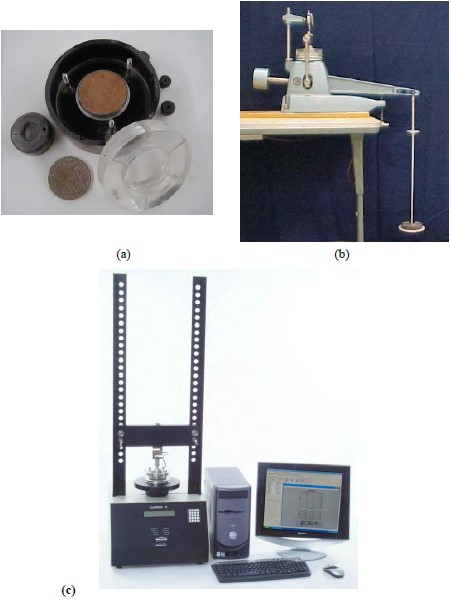

Figure 1-6 shows a schematic of a consolidation test. The consolidation-loading device may be a weighted lever arm as shown in Figure 1-7b, a pneumatic device, or an automated loading frame as shown in Figure 1-7c. Automated loading frames are recommended for use in production testing because they provide the most flexibility in testing options. The pneumatic device provides flexibility in loads and load increment ratios (LIR) that can be applied during testing. A weighted lever arm provides a robust, relatively simple system for consolidation testing, however, because data are generally recorded manually, it is difficult to expedite testing or vary the loading schedule since data reduction cannot typically be performed in real time.

Consolidation cells may be either fixed ring or floating ring. Friction and drag are created in the ring as the specimen compresses in relation to the ring. In a fixed ring test the sample compresses from the top only, potentially resulting in high incremental side shear forces. In a floating ring test the sample compresses from the top and bottom thus providing the advantage of minimizing drag forces. However, the floating ring method has the following disadvantages: it is more difficult to set up; it has the potential for sidewall leakage that would result in an inaccurate assessment of the rate of consolidation, and soil may squeeze out near the junction of the sidewall and the bottom porous disc. Because of these disadvantages, the fixed ring method is most commonly used.

1.4.3 Procedures

The consolidation properties of fine-grained soils are evaluated in the laboratory by using the one-dimensional consolidation test. The most common laboratory method is the incremental load (IL) method (ASTM D 2435). The weighted lever arm oedometer shown in Figure 1-7b is commonly used for performing the procedure. The automated load-frame apparatus shown in Figure 1-7c provides higher quality test results compared to the weighted lever apparatus. High-quality undisturbed samples obtained by using Shelby tubes (ASTM D 1587), piston samplers, or other special samplers are preferred for laboratory consolidation tests.

1.4.4 Presentation and Understanding the Consolidation Test Results

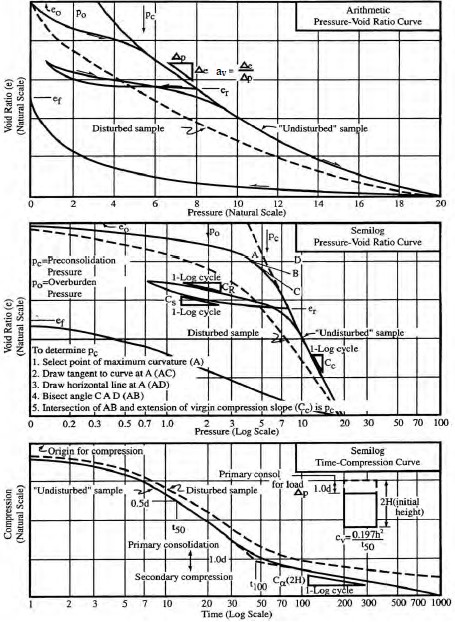

The consolidation test should be run in such a way that sufficient time is allowed for the applied pressure (total stress) increment to be transmitted from the pore water, where it acts initially as a excess pore water pressure, to the soil structure where it ultimately becomes an applied effective stress increment. The time it takes for this transfer to occur is the basis for the process being called “consolidation” and not “compression.” Therefore, the effective stress corresponding to the applied pressure is generally plotted versus void ratio. The resulting “consolidation curve” permits an evaluation of the preconsolidation pressure and values for other parameters pertaining to the consolidation characteristics of the soil sample.

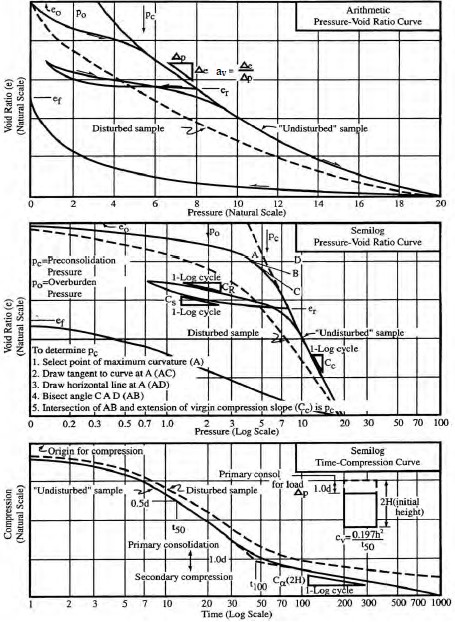

Plots of void ratio versus effective pressure on arithmetic and logarithmic scales are shown in Figure 1-8. The semi log plot is more widely used in practice and will be used in subsequent sections of this manual. The consolidation curve on the void ratio versus semi log pressure plot is commonly referred to as the “e-log p” relationship. As shown on Figure 1-8, the slope of the loading portion of the e-lop p curve is called the compression index, which is denoted by the symbol Cc. The slope of the re-load portion of the e-log p curve is called the re-compression index; it is denoted by the symbol Cr.

Some geotechnical specialists prefer to use a plot of percent strain versus log of pressure instead of the e-log p plot. In this case the slope of the virgin compression portion of the consolidation curve is called the modified compression index denoted by the symbol Ccε and the slope of the rebound portion of the curve is called the modified recompression index denoted by the symbol Crε. The modified indices reflect the relationship between strain and void ratio, i.e., strain (ε) = Δe/(1+eo). Therefore, to convert the strain-based indices (Ccε and Crε) to the void-ratio-based indices (Cc and Cr) multiply the strain based values by (1 + eo). Void-ratio-based values (e-log p) will be used in the remainder of this manual.

Analysis of consolidation test data allows the engineer to determine:

- Initial Void Ratio (eo)The value of the initial void ratio is very important because it defines the amount of void space at the start of the loading. It is this initial void space that will be reduced as the water is squeezed out of the voids with time. The initial void ratio eo is a key parameter used in settlement computations to determine the magnitude of settlement.

Figure 1-8. Consolidation test relationships (after NAVFAC, 1986a). - Preconsolidation Pressure (pc)The e-log p relationship generally displays a distinct break at approximately the maximum past effective stress (pc). The graphical technique developed by Casagrande (1936) is generally used to determine the value of pc, which is known as preconsolidation pressure. The Casagrande procedure is included in the middle portion of Figure 1-8.The maximum effective stress to which a soil has been loaded in the past will have a major influence on the amount of settlement to be expected under a proposed loading. In fact, 10 times more settlement may occur in a normally consolidated soil than a preconsolidated soil for equal load increments up to the preconsolidation pressure. Values of preconsolidation pressure should be carefully established for the entire depth of the fine-grained soil deposit under consideration. Normally, a minimum, maximum and most probable value of pc will be determined from laboratory test results and plotted as a range with depth.

- Compression Index (Cc)The slope of the consolidation curve beyond pc is called the compression index (Cc). It is a measure of the load-deformation characteristic of the soil during “virgin” compression.

- Recompression Index (Cr)An unload/reload segment of the consolidation curve is also shown in Figure 1-8. The slope of the reload curve is called the recompression index (Cr). It is a measure of the load-deformation characteristic of the soil upon reloading after some amount of load release. As is obvious in Figure 1-8, the slope of the reload portion of the consolidation curve is not as steep as the slope of the virgin portion of the curve since the void ratio change accompanying the virgin loading is unrecoverable. Figure 1-8 also shows that if, upon reloading, the applied pressure exceeds the pressure from which the soil was unloaded, the slope of the reload curve reverts back to the virgin compression slope, Cc. In general, Cc ≈ 10 Cr.

- Coefficient of Consolidation (cv)The coefficient of consolidation is an indicator of the rate of drainage during consolidation. The value may be determined by the t50 (log time) method or the t90 (square root of time) method. As shown in the bottom portion of Figure 1-8, the compression-log time curve for a given load increment is used to determine the coefficient of consolidation (cv), which is a measure of the time rate of primary consolidation. The value of cv is determined for each load increment. These values are sometimes plotted on a separate axis below the consolidation curve

- Secondary Compression Index (Cα)Of great importance in organic materials, secondary compression may account for the majority of settlement that takes place over a long period of time in such soils. The compression-log time curve for a given load increment is used to determine the secondary compression index (Cα), which is basically the slope of the curve over one log cycle beyond the time required for primary consolidation (t100) as shown in the bottom portion of Figure 1-8.

- Effects of Sample Disturbance on Consolidation Test ResultsThe influence of sample disturbance on consolidation test results is shown on Figure 1-8 by the dashed lines. The dash lines indicate that disturbance:

- Eliminates the distinct break in the e-log p curve at the preconsolidation pressure (pc).

- Lowers the estimated value of the preconsolidation pressure (pc) and the measured value of the compression index (Cc).

- Decreases the measured values of cv.

- Increases the recompression index (Cr).

- Decreases the secondary compression index (Cα).

The general effects of disturbance are (a) under- or over-prediction of the magnitude of expected settlement and (b) over-prediction of the time for its occurrence.

The importance of the consolidation test results as applied to design is summarized below. The test results may be applied to project design after a series of tests have been completed to represent the total depth of the fine-grained soil deposit. The two most important predictions are:

- The amount of settlement. The value is determined by analyzing the consolidation curve between the existing overburden pressure and the final pressure induced by the highway load at various depths. The amount of settlement may vary dramatically depending upon the maximum past pressure to which the soil has been loaded. The total amount of long-term settlement should include an estimate of settlement due to secondary compression, especially for times past the time for 100% primary consolidation if that is less than the design life of the constructed facility.

- The time for settlement. The time for primary consolidation to occur may be estimated from the results of the compression versus time plots at loads between the overburden pressure and final pressure induced by the applied load. The important factors in the settlement-time relationship are:

- Time required is proportional to the square of the longest distance required for water to drain from the deposit. This distance is the thickness of the layer if water drains in one direction only (generally vertically upward to the surface), and one-half the layer thickness if more permeable soils exist above and below the consolidating layer.

- Time required for consolidation varies inversely with the coefficient of consolidation.

- Rate of settlement decreases as time increases.

1.4.5 Comments on the Consolidation Tests

The consolidation test results are necessary to assess the consolidation properties of the soil. As will be shown in subsequent sections of this document, the consolidation test is one of the most important tests for fine-grained soil as it provides data regarding stress history and compressibility. It is important to consider all laboratory testing variables and their potential effects on the values of soil properties computed from the test results. Information that will need to be provided to a laboratory for a consolidation test includes the loading schedule (i.e., magnitude and duration of loads). It is important to evaluate the loading schedule to be used, especially the duration of loading since time is required for the applied total stress increment to be transferred from the pore water to the soil structure so that it becomes an effective stress acting on the soil mass. Important issues related to consolidation tests are discussed below.

- Loading Sequence: The loading sequence selected for a consolidation test will depend on the type of soil being tested and the particular application being considered for the project (e.g., embankment, shallow foundation). The selection of a loading sequence should never be left to the discretion of the laboratory. As an example, if the clay soil is heavily over consolidated, it is possible that a laboratory-determined maximum load for the consolidation test will not be sufficient to exceed pc.

- Range of Applied Loads: The range of applied loads for the test should well exceed the effective stresses that are required for settlement analyses. This range should cover the smallest and largest effective stresses anticipated in the field and will depend on depth, foundation loads, and excavations. The anticipated preconsolidation stress should be exceeded by at least a factor of four during the laboratory test. If the preconsolidation stress is not significantly exceeded during the loading schedule, pc, and Cc (or Ccε) may be underestimated due to specimen disturbance effects.

- Load Increment Ratio (LIR): By definition the LIR= Δσ/σinitial where Δσ is the incremental stress and σinitial is the previous stress. A LIR=1 corresponds to a doubling of the vertical stress applied to the specimen at each successive load increment during a consolidation test. A LIR of 1 is commonly used for most tests. Experience with soft sensitive soils suggests that as the stress approaches the value of pc, a smaller LIR will facilitate a better estimate of pc. Typically, laboratories provide a unit cost for a consolidation test that may be based on 6 to 8 load increments with a separate cost for each additional increment.

- Unload-Reload Cycle: It is recommended that an unload-reload cycle be performed, especially for cases where accurate settlement predictions are required, specifically to obtain a value for Cr. Since most samples will inevitably be somewhat disturbed, a Cr value based on the initial loading of a consolidation test sample will be greater than that for an undisturbed sample, resulting in an overestimation of settlements in the over consolidated region. A value of Cr based on an unload-reload cycle is more likely to be representative of the actual behavior of the soil in the over consolidated region.

- Duration of Load Increment: The duration of each load increment should be selected to ensure that the sample is approximately 100 percent consolidated prior to application of the next load increment. For relatively low to moderate plasticity silts and clays, durations of 3 to 12 hours will be appropriate for loads in the normally consolidated range. For fibrous organic materials, primary consolidation may be completed in 15 minutes for each load increment. For high plasticity materials, the duration for each load increment may need to be 24 hours or more to ensure complete primary consolidation and to evaluate secondary compression behavior. Conversely, primary consolidation may occur in less than 3 hours for loads less than pc. If the time period is too short for a given load increment (i.e., the sample is not allowed to achieve approximately 100 percent consolidation before the next load increment is applied), then values of Cc may be underestimated and values of cv may be overestimated. The duration of time required, however, can be optimized by using pneumatic, hydraulic, or electro-mechanical loading systems that include automated loading and data acquisition systems. Continuous deformation versus time measurements and the square root of time method can be used to estimate the beginning and end of primary consolidation during the test. Once the end of primary consolidation is detected, the system can automatically apply the next load increment. Alternatively, some laboratories can provide real-time deformation versus log time plots to enable the engineer to evaluate whether 100 percent primary consolidation has been achieved.

- Secondary Compression: In cases where secondary compression is important (e.g., organic soils), secondary compression should be assessed on the basis of the deformation versus log-time response. The consolidation test for each load increment should be run long enough to establish a linear trend between vertical displacement and log time.

1.4.6 Useful Correlations between Consolidation Parameters and Index Values

This section presents some useful correlations between consolidation parameters and other index values. These correlations can be used by the designer to check the validity of the laboratory tests results or to develop a prediction of the range of values of consolidation parameters that can be expected from yet-to-be performed consolidation tests. It must be emphasized that predictions based on correlations should never be substituted for proper testing and that any assumptions regarding consolidation parameters should always be verified through testing.

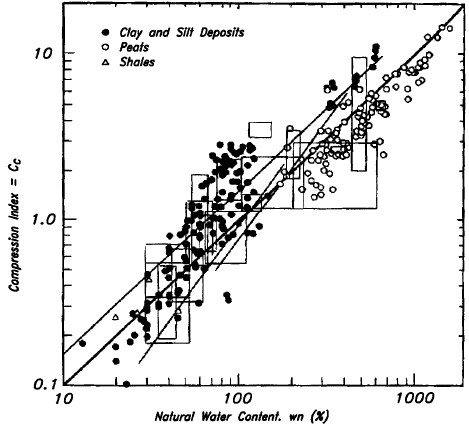

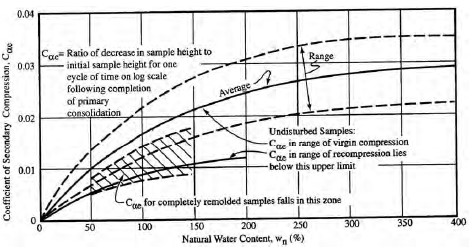

1.4.6.1 Compression Index, Cc

Over 70 different equations have been published for correlating Cc with the index properties of clays. Table 1-5 lists some of the more useful correlations. Figure 1-9 shows correlations between natural water content and Cc for fine-grained soils, peats and shales. Note that the coordinates in Figure 1-9 are both logarithmic so that values of Cc can vary by as much as a factor of 5 with respect to the average trend line in these empirical correlations. Values of Cc obtained from Table 1-5 or Figure 1-9 should not be used for final design.

1.4.6.2 Recompression Index, Cr

The ratio of Cr / Cc typically ranges from 0.02 to 0.20 (Terzaghi, and Peck, 1967). The low value is typical of highly structured and bonded soft clay or silt, while the largest ratio corresponds to micaceous silts and fissured stiff clays and shales. In reality, the value of Cr depends on whether loading or unloading is occurring, since some hysteresis effects develop when the soil is subjected to cycles of loading and unloading.

Generally, it is sufficiently accurate to assume Cr is constant for most clay deposits. It may not be adequate to rely on a single value of Cr for loading and unloading in the case of highly structured soft clays or stiff clay shales. In the case of highly structured soft clays the initial value of Cr is steep as a result of flocculation (edge to face structure of clays) and bonding that allows the soil to be stable at high void ratios until the stress exceeds the preconsolidation pressure (Terzaghi and Peck, 1967). The subsequent rebound slope can be significantly different from the initial Cr.

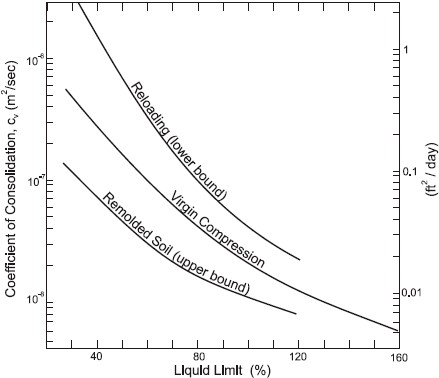

1.4.6.3 Coefficient of Vertical Consolidation, cv

Because of the wide range of permeabilities that exist in soils (see Table 1-10), the coefficient of consolidation can itself vary widely, from less than 10 ft2/yr (≈1 m2/yr) for clays of low permeability to 10,000 ft2/yr (≈1,000 m2/yr) or more for very sandy clays, fissured clays and weathered rocks. Some typical values for clays are given in Table 1-6 and an approximate correlation with liquid limit is shown in Figure 1-10.

Just as permeabilities in the horizontal and vertical directions can be significantly different due to variations in soil particle orientation, non-homogeneity, etc., so too can the in situ coefficient of horizontal consolidation, ch, be much different from the coefficient of vertical consolidation cv measured in the laboratory for the same reasons. For example, the in situ coefficient of horizontal consolidation, ch, for clays containing fissures or fine bands of sand, may often be much greater than cv measured in the laboratory for the clay alone. In such cases, the in-situ ch may govern the actual rate of consolidation under field loading conditions.

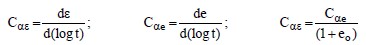

1.4.6.4 Coefficient of Secondary Compression, Cα

Table 1-7 presents typical values of Cα in terms of Cc for various geomaterials. As shown below by Equations 1-7, the coefficient, Cα, may be expressed either in units of strain (Cαε) or void ratio (Cαe) per log cycle of time. As indicated previously, to convert void-ratio-based consolidation curve indices to strain-based indices divide the void-ratio-based values by (1 + eo).

Cαe is usually assumed to be related to Cc with values of Cαe/Cc typically in the range 0.0250.006 for inorganic soils and 0.035-0.085 for organic soils. Figure 1-11 presents a correlation between Cαe and natural water content.

1.5 Shear Strength of Soils

The shear strength of soils is extremely important to foundation design. In addition, slopes of all kinds, including hills, river banks, and man-made cuts and fills, stay in place only because of the shear strength of the material of which they are composed. Knowledge of the shear strength of soil is important for the design of structural foundations, embankments, retaining walls, pavements, and cuts. Table 1-8 provides a summary of specific issues related to the design and construction of typical highway design elements that should be considered in developing and implementing a laboratory and in-situ testing program for evaluating soil shear strength.

1.5.1 Concept of Frictional and Cohesive Strengths

The concept of shear strength was shown to be comprised of two components, friction (φ) and cohesion (c). In terms of the classification of soils, these two components of the shear strength can be generalized as follows:

- Coarse-grained soils, such as gravel and sand, and fine-grained silt, derive strength primarily from friction between particles. Therefore they are considered to be “cohesion less” or “frictional” soils and are often denoted as “φ-soils.”

- Fine-grained soils, composed mainly of clay, derive strength primarily from the electro-chemical attraction, or bond, between particles. Therefore they are considered to be “cohesive” soils and are often denoted as “c-soils.”

- Mixtures of cohesion less and cohesive soils derive strength from both interparticle friction and bonding. Such soils are commonly denoted as “c-φ soils.”

1.5.1.1 Strength Due to Friction

The strength due to friction between soil particles is dependent on the stress state of the soil (e.g., overburden pressure) and the angle of internal friction (φ) between the particles. The frictional resistance of soil is equal to the normal stress, σn, times the tangent of friction angle, φ. The tangent of φ is equal to the coefficient of friction (μ) between the soil particles.

The equation for frictional resistance, τ, is written in terms of normal stress, σn, as follows:

The coefficient of friction, tan φ, between individual particles depends on both their mineral hardness and surface roughness. However, the measured friction angle of a soil sample or deposit also depends on the density of the mass caused by interlocking of particles. For a detailed discussion of factors affecting frictional resistance, the reader is referred to textbooks such as by Holtz and Kovacs (1981).

1.5.1.2 Strength Due to Cohesion

The concept of cohesive strength is more difficult to explain and often misunderstood. The designer must develop a good understanding of this concept otherwise there will be a disconnect between reality and the design of some structures, e.g., the first bench cut in shoring.

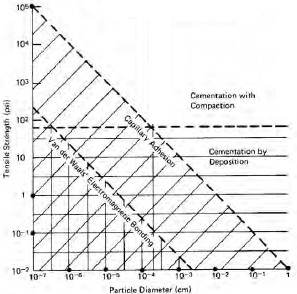

There are two types of cohesion in soils: true cohesion and apparent cohesion. These are briefly discussed as follows (after Mitchell, 1976):

- True cohesion may result from chemical cementation (just like in rocks) and/or forces of attraction (e.g., electrostatic and electromagnetic attractions) between colloidal (10-3 mm to 10-6 mm) clay particles. True cohesion is stress-independentunlike frictional resistance that is a function of normal stress.

- Apparent cohesion may develop because of capillary stresses and mechanical interlocking as follows:

- Capillary stresses develop between particles in a partially saturated soil due to surface tension in the water. The surface tension (negative pressure) in the water produces an equal and opposite effective stress between the soil particles, which results in an apparent cohesion since it too is stress-independent. The magnitude of this type of apparent cohesion can be extremely large, especially in fine-grained soils. Such capillary stresses can be overcome by an increase in the degree of saturation.

- Apparent mechanical forces are often exhibited by the interlocking of rough(angular) soil particles. The interlock between the soil particles can offer some resistance to shear stresses even in the absence of a normal stress. This type of apparent cohesion is often the cause of cohesion measured in compacted soils. However, such apparent mechanical forces are susceptible to significant reduction by vibrations and other types of mechanical disturbance.

Figure 1-12 presents a graphical representation of the potential contribution of various mechanisms of cohesion. It can be seen that true cohesion in soils exists only when the particle size is colloidal. Unless the complete soil sample is composed of colloidal particles, true cohesion due to interparticle attraction cannot be relied on. Cementation by deposition is often observed in arid environments (e.g., desert southwest), but it is difficult to quantify. As indicated above, capillary stresses can provide a large apparent cohesion, but such cohesion can be overcome by saturation. Since cohesion cannot be defined with confidence, its contribution to long-term shear strength in c-φ soils is often disregarded or greatly minimized by using only a small value such as 100 to 500 psf (5 to 25 kPa). For purely cohesive soils, the designer should be careful in evaluating the cohesion for long-term design purposes. Further discussion on apparent cohesion in the context of compacted soils is included in Section 1.8.4.1.

1.5.1.3 Simplified Expression for Shear Strength of Soils

The shear strength, τ, of soils is expressed simplistically by two additive components as follows:

In terms of effective stresses, the effective shear strength, τ′, can be re-written as follows:

where u is the pore water pressure, c′ is the effective cohesion, σ′ is the effective normal stress, and φ′ is the effective friction angle.

The shear strength soil is influenced by many factors including the effective stress state, mineralogy, packing arrangement of the soil particles, soil hydraulic conductivity, rate of loading, stress history, sensitivity, and other variables. As a result, the shear strength of soil is not a unique property. The following sections present and discuss various laboratory tests to determine the shear strength for various types of construction and loading conditions. Typical laboratory strength tests are introduced including the unconfined compression test (AASHTO T208; ASTM D 2166), the triaxial test (AASHTO T234; ASTM D 4767), and the direct shear test (AASHTO T236; ASTM D 3080). A detailed discussion on testing equipment and procedures is beyond the scope of this document. The interested reader should review the AASHTO and ASTM standards for detailed information on testing equipment and procedures. The following sections also describe information that must be conveyed to a laboratory testing firm to ensure that the strength testing is performed consistent with the requirements imposed by the design (e.g., selection of confining pressures consistent with the imposed loads).

1.5.2 Strength Testing of Soils in the Laboratory

The shear strength of a soil is the maximum shear stress that the soil structure can resist before failure. Failure is generally defined as continuing displacement without an increase in applied stress. Since the water filling the pores has no shear strength, shear stresses are carried by the structure of soil grains. However, the shear strength of the soil structure is indirectly dependent on the pressure in the pore water, which influences the friction term as shown by the excess pore water pressure term, u, in Equation 1-10. Foundation designers must consider the effects of expected construction operations on the subsoils when planning a test program. For example, when a highway embankment or structural footing is suddenly placed on a soft clay deposit, the pore water initially carries all the load and the available shear strength does not increase until drainage begins and the excess pore water pressure decreases. In planning a test program for such a situation the designer should request unconsolidated undrained (UU) triaxial tests to determine the undrained shear strength of the soil which, in this case, would be the critical strength value, i.e., the initial shear strength before consolidation begins. Additional consolidated undrained (CU) or consolidated drained (CD) tests would also be used to determine the increase in shear strength as consolidation occurs and excess pore water pressures dissipate. These results can be used to determine alternate methods of applying the loads safely, especially if the undrained strength is insufficient to sustain the proposed loading. Stage construction involves placement of an increment of load and a waiting period to allow strength gain through excess pore water pressure dissipation so the soil deposit can safely support the next load increment.

The majority of strength tests are conducted on cohesive soils since obtaining undisturbed samples of non-cohesive soils is difficult. Strength tests on cohesive soils are usually conducted on high quality undisturbed samples obtained from thin wall sampling tubes. The preferred test for most projects where cohesive soils are involved is the triaxial compression test. The number and types of tests must be selected by the designer to suit the project conditions. For each test the designer should clearly indicate the consolidation or confining pressure to be used. These pressures are determined from the po diagram for each specific project. The range usually extends from the effective overburden pressure to the pressure induced by the highway loading. The program objective should be to establish a profile of soil strength with depth. Soil strength parameters are frequently expressed as a ratio of shear strength over the effective overburden pressure (τ/po).

The most common laboratory soil strength tests are:

- Unconfined compression test

- Triaxial compression test, and

- Direct shear test

Each of these tests is briefly discussed below. For the triaxial compression and the direct shear tests, it is important that each test be performed on a new sample. The practice of performing multi-stage shear strength tests on a single sample is not recommended.

1.5.2.1 Unconfined Compression (UC) Tests

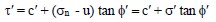

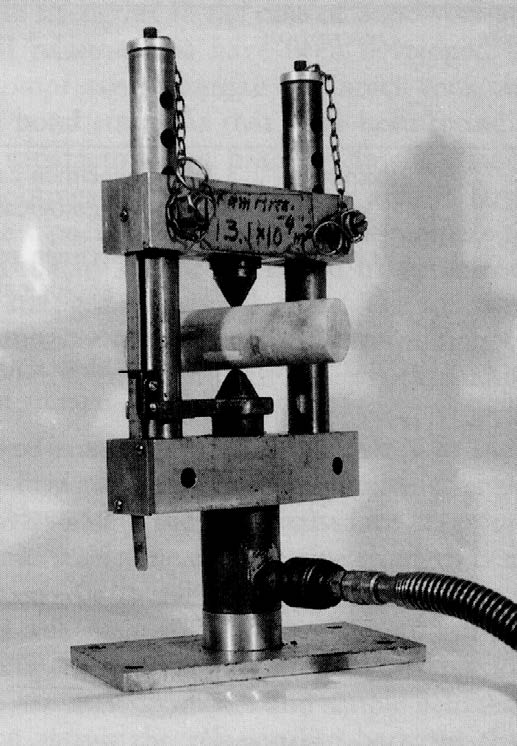

The unconfined compression test is a quick, relatively inexpensive means to obtain an estimation of the undrained shear strength of cohesive specimens. In this test a cylindrical specimen of the soil is loaded axially as shown in Figure 1-13 without any lateral confinement to the specimen, at a sufficiently high rate to prevent drainage. Since there is no confinement, residual negative pore pressures that may exist in the sample following sample preparation generally control the state of effective stress in the sample. The shear stresses induced in the specimen by the axial load result in a shear failure. The magnitude of the shear stress at the moment of failure represents the shear strength of the soil under these conditions of loading and drainage. Therefore, the shear strength obtained from this test is called the “undrained shear strength (su).” In most cases, the value of undrained shear strength obtained from an unconfined compression test is conservative. The maximum axial compressive stress measured at failure represents the compressive strength of the soil under these conditions of loading, drainage, and confinement. Therefore, the compressive strength obtained from this test is called the “unconfined compressive strength (qu).” These two strengths terms should not be confused; one is a shear strength the other a compressive strength. It can be shown graphically by a Mohr’s circle construction (Appendix B) that the undrained shear strength (su) is equal to one-half the unconfined compressive strength (qu).

The unconfined compression test cannot be performed on granular soils, dry or crumbly soils, silts, peat, or fissured or varved materials. Because there is no control over the effective stress state of the specimen, this test is not recommended for evaluating strength properties for compressible clay soils subjected to embankment or structural foundation loads. The reliability of this test decreases with increasing sampling depth because the sample tends to swell after removal from the ground due to confining stress release. The swelling results in greater particle separation and reduced shear strength. Testing the full diameter extruded specimen as soon as possible after removal from the tube can:

- minimize swelling

- reduce disturbance

- preserve the natural moisture content.

Unfortunately, despite these shortcomings, this test is commonly used in practice because of its simplicity and low cost.

1.5.2.2 Triaxial Tests

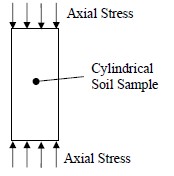

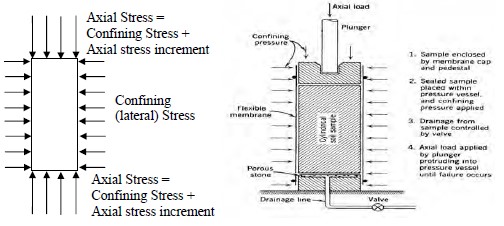

The triaxial test is very versatile in the sense that the shear strength can be evaluated under compression as well as extension loading conditions. A schematic of triaxial compression test is shown in Figure 1-14 where the axial stress is greater than the confining stress. Lateral pressures at various depths below the ground surface can be simulated by confining pressures. Note that the confining pressures acts on the entire sample and is equal to the axial stress before the application of an axial stress increment. Typically, failure of the sample is caused by increasing the axial stress (compression) until a shear failure takes place. In an extension test, the confining pressures are increased while keeping the axial stress constant. Pore water pressures during the test can be measured.

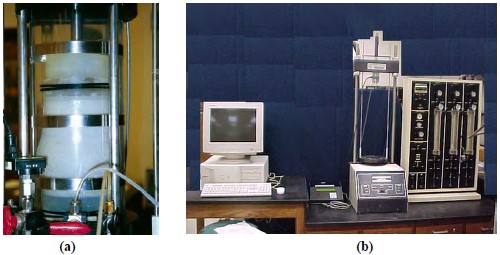

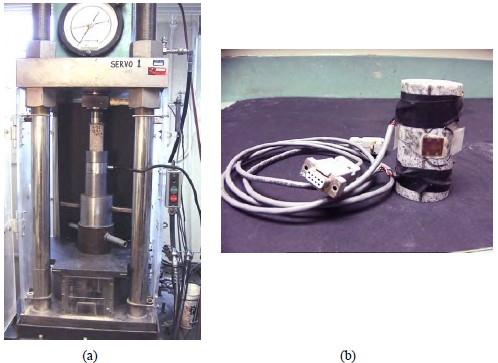

Equipment – Triaxial systems today use electronic instrumentation to provide continuous monitoring and periodic acquisition of test data (see Figure 1-15b). Force is measured by using a force transducer or load cell that is typically mounted outside the triaxial cell. More advanced systems have the transducer incorporated within the testing cell to reduce the effects of rod-friction. Linear variable differential transducers (LVDTs) are used to monitor deformations. Additionally, volume measurements can be taken with a device that makes use of an LVDT to measure the rise or fall of a bellofram cylinder. This change in movement is calibrated to the volume of water taken in or pushed out of the sample. Pressure transducers are mounted on the base of the test cell to monitor the confining pressure within the cell and the pore water pressure within the sample.

Unconsolidated-Undrained (UU) Test

In the UU test, no drainage or consolidation is allowed during either the application of the confining pressure or the application of the axial load that induces shear stress. The shear stresses induced in the specimen by the axial load result in failure. As indicated in Section 1.5.2, the UU test models the response of a soil that has been subjected to a rapid application of an axial load such as that due to construction of an embankment. It is difficult to obtain repeatable results for UU testing due to the effects of sample disturbance. The accuracy of the UU test is dependent on the soil sample retaining its original structure until testing occurs. The undrained shear strength of the soil, su, is measured in this test.

Consolidated-Drained (CD) Test

In the CD test, the specimen is allowed to consolidate completely under the confining pressure prior to the application of axial load, i.e., the confining pressure acts as an effective stress throughout the soil specimen. The axial load is applied at a rate slow enough to allow drainage of pore water so that there is no buildup of excess pore water pressures, i.e., the stresses imposed by the axial load are effective stresses. The shear stresses induced in the specimen by the axial load result in failure. The time required to conduct this test in low permeability soil may be as long as several months. Therefore it is not common to conduct a CD test on low permeability soils. The CD test models the long-term (drained) condition in soil. Effective stress strength parameters (i.e., φ′ and c′) are evaluated from the results of the CD test.

Consolidated-Undrained (CU) Test

The initial part of the CU test is similar to the CD test in that the specimen is allowed to consolidate under the confining pressure. However, unlike the CD test, the axial load is applied with the drainage lines closed in the CU test. Thus, during shearing there is continual development (+ or -) of excess pore water pressure. The rate of axial load application for this test is more rapid than that for a CD test. Pore pressures are typically measured during the CU test so that both total stress and effective stress strength parameters can be obtained. Recall that total stress equals effective stress + pore water pressure as expressed by Equation 1-13. The pore water pressure may be + or – depending upon whether the specimen dilates or compresses during application of the axial load. The shear stresses induced in the specimen by the axial load result in failure. The effective stress parameters evaluated for most soils based on CU testing with excess pore water pressure measurements will be similar to those obtained from CD testing, thus making CD tests unnecessary for typical applications.

During triaxial testing, the confining pressure, which acts uniformly over the entire specimen, is considered to be the minor principal stress. By definition, a principal stress is one that acts on a plane where shear stress is zero. The interface between the soil and the membrane isolating it from the fluid in the chamber is assumed to be frictionless during the entire test, i.e. no shear stresses develop along the circumference of the specimen. Likewise, the applied axial load causes a normal stress to act on the top and bottom of the specimen. As shown in Figure 1-14, this vertical normal stress acts in addition to the confining pressure. Therefore, the combined vertical stress acting on the top and bottom of the specimen during the triaxial test is considered to be the major principal stress not only because the plane (horizontal) on which it acts is orthogonal to the minor principal stress plane (vertical), but mainly because the interface shear stress between the specimen and the top and bottom caps is assumed to be equal to or close to zero. To assure this condition, the end caps are usually coated with a lubricant to make them virtually frictionless. Because of these boundary stress conditions, the specimen is free to shear on a plane consistent with the directions of the major and minor principal stress planes and its inherent shear strength as expressed by c and φ.

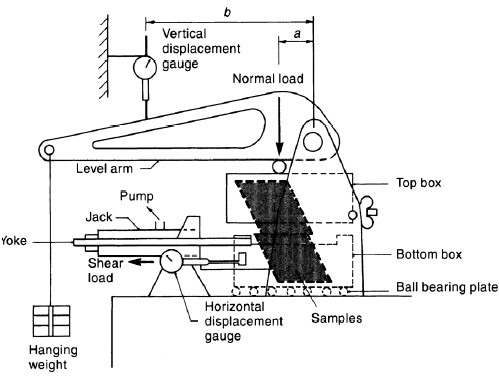

1.5.2.3 Direct Shear Tests

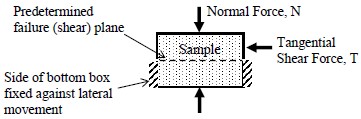

The oldest form of shear test upon soil is the direct shear test, first used by Coulomb (1776). A schematic of the essential elements of the direct shear apparatus are shown in Figure 1-17. The soil is held in a box that is split across its middle; the bottom portion of the box is usually fixed against lateral movement. A confining normal force, N, is applied, and then a tangential shear force, T, is applied so as to cause relative displacement between the two parts of the box. The magnitude of the shear force is recorded as a function of the shear displacement, and usually, the change in thickness of the soil sample is also recorded. Although it is widely used in practice, the direct shear device lacks a number of features that limit is applicability. For example, there is no way to control the confining pressure. Also, since there is no way to measure excess pore water pressures generated during shearing of saturated clay specimens, use of the direct shear test is generally limited to cohesionless soils.

Equipment – The apparatus and procedures for direct shear testing are discussed in ASTM D 3080. A specimen is prepared in a split square or circular box. Figure 1-18 shows a circular specimen. The specimen is sheared as one part of the box is displaced horizontally with respect to the other. Generally, the lower part of the box is fixed against lateral movement and the shear force is applied to the upper part of the box through a loading frame as shown in Figure 1-18. The central two of the six screws visible in the top portion of the box extend into the bottom portion and are used to hold the assembly together while the specimen is being prepared. This shear box assembly is then placed in a reservoir which could be filled with water to allow saturation of the specimen prior to shearing. Before the test is begun, the two central screws are removed and the four corner screws, which rest on the top surface of the bottom portion of the box, are turned to slightly raise the top part of the box so that there is no contact between it and the bottom part of the box. This is done to prevent the error that would result from the frictional resistance between the two boxes at their contact. Load cells are used to monitor the shear force and LVDTs are used to monitor both horizontal and vertical deformation. By use of this instrumentation, as well as a loading frame that provides a constant rate of horizontal deformation, it is possible to automate the direct shear test.

Test Procedures – In the direct shear test, the soil is first consolidated under an applied normal stress. After consolidation is completed, which will be virtually instantaneous in cohesionless soils, the specimen is sheared directly at a constant rate. The rate of shear is typically selected as a function of the hydraulic conductivity of the specimen. Direct shear testing is commonly performed on compacted materials used for embankment fills and retaining structures. Direct shear testing can also be performed on natural materials. However, the lack of control on soil specimen drainage makes the evaluation of undrained strength unreliable. The direct shear test can also be used to evaluate the drained strength of natural materials by shearing the sample at a rate slow enough to ensure that no significant pore water pressures develop, however there is no way to verify this condition by measurement.

In addition to providing data that allows the determination of the peak effective stress friction angle (φ′), the direct shear test data can also be used for the evaluation of effective stress residual strengths (c′r ≈ 0; φ′r). The effective stress residual strength parameters are necessary for stability and landslide analyses. Residual strengths are associated with very large shear strains along a predefined or preferential slip surfaces that result in very large deformations. Data from a reversing direct shear test can also be used to evaluate residual shear strengths. In a reversing direct shear test, the direction of shearing in the test is reversed several times thereby causing the accumulation of displacements at the slip surface.

A characteristic of the direct shear test that distinguishes it from the triaxial test is that the shear failure in the direct shear device is forced to occur on a horizontal plane so that the orientations of the major and minor principal stress planes are not apparent. Ordinarily this characteristic is considered to be a disadvantage of the direct shear test. However this characteristic is advantageous for designs involving geosynthetics where the shearing resistance of the interface between the soil and the geosynthetic or between two pieces of geosynthetic is often required. Direct shear machines have been modified to test the interface shear strength between various types of engineering materials, as described in ASTM D 5321.

1.5.3 Factors Affecting Strength Testing Results