1: Introduction to Systems Engineering Management 1

1.1 PURPOSE

This chapter establishes some of the basic premises that are expanded throughout this course. Basic terms explained in this chapter are the foundation for following definitions. Key systems engineering ideas and viewpoints are presented, starting with a definition of a system.

1.2 DEFINITIONS

A System Is …

Simply stated, a system is an integrated composite of people, products, and processes that provide a capability to satisfy a stated need or objective.

Systems Engineering Is…

Systems engineering consists of two significant disciplines: the technical knowledge domain in which the systems engineer operates, and systems engineering management. This course focuses on the process of systems engineering management.

Three commonly used definitions of systems engineering are provided by the best known technical standards that apply to this subject. They all have a common theme:

- A logical sequence of activities and decisions that transforms an operational need into a description of system performance parameters and a preferred system configuration. (MIL-STD-499A, Engineering Management, 1 May 1974. Now cancelled.)

- An interdisciplinary approach that encompasses the entire technical effort, and evolves into and verifies an integrated and life cycle balanced set of system people, products, and process solutions that satisfy customer needs. (EIA Standard IS-632, Systems Engineering, December 1994.)

- An interdisciplinary, collaborative approach that derives, evolves, and verifies a life-cycle balanced system solution which satisfies customer expectations and meets public acceptability.(IEEE P1220, Standard for Application and Management of the Systems Engineering Process, [Final Draft], 26 September 1994.)

In summary, systems engineering is an interdisciplinary engineering management process that evolves and verifies an integrated, life-cycle balanced set of system solutions that satisfy customer needs.

Systems Engineering Management Is…

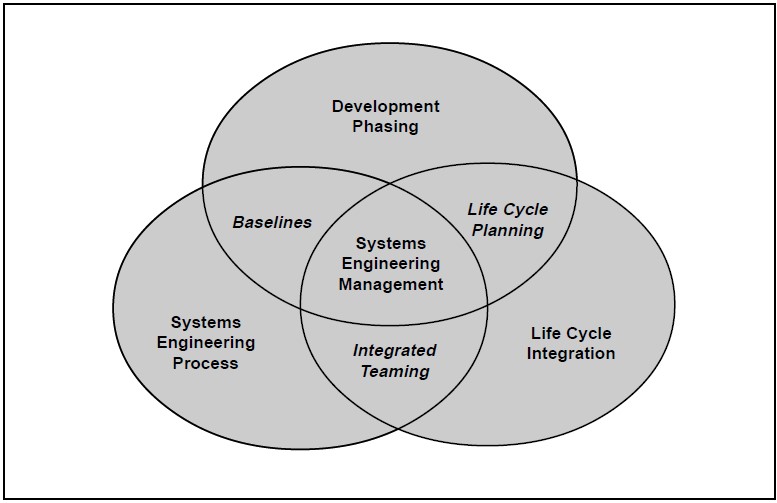

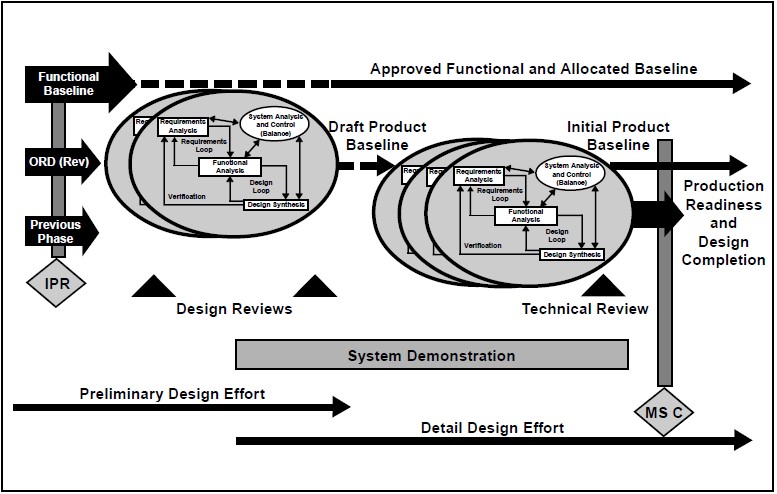

As illustrated by Figure 1-1, systems engineering management is accomplished by integrating three major activities:

- Development phasing that controls the design process and provides baselines that coordinate design efforts,

- A systems engineering process that provides a structure for solving design problems and tracking requirements flow through the design effort, and

- Life cycle integration that involves customers in the design process and ensures that the system developed is viable throughout its life.

Each one of these activities is necessary to achieve proper management of a development effort. Phasing has two major purposes: it controls the design effort and is the major connection between the technical management effort and the overall acquisition effort. It controls the design effort by developing design baselines that govern each level of development. It interfaces with acquisition management by providing key events in the development process, where design viability can be assessed. The viability of the baselines developed is a major input for acquisition management Mile-stone (MS) decisions. As a result, the timing and coordination between technical development phasing and the acquisition schedule is critical to maintain a healthy acquisition program.

The systems engineering process is the heart of systems engineering management. Its purpose is to provide a structured but flexible process that transforms requirements into specifications, architectures, and configuration baselines. The discipline of this process provides the control and trace-ability to develop solutions that meet customer needs. The systems engineering process may be repeated one or more times during any phase of the development process.

Life cycle integration is necessary to ensure that the design solution is viable throughout the life of the system. It includes the planning associated with product and process development, as well as the integration of multiple functional concerns into the design and engineering process. In this manner, product cycle-times can be reduced, and the need for redesign and rework substantially reduced.

1.3 DEVELOPMENT PHASING

Development usually progresses through distinct levels or stages:

- Concept level, which produces a system concept description (usually described in a concept study);

- System level, which produces a system description in performance requirement terms; and

- Subsystem/Component level, which produces first a set of subsystem and component product performance descriptions, then a set of corresponding detailed descriptions of the products’ characteristics, essential for their production.

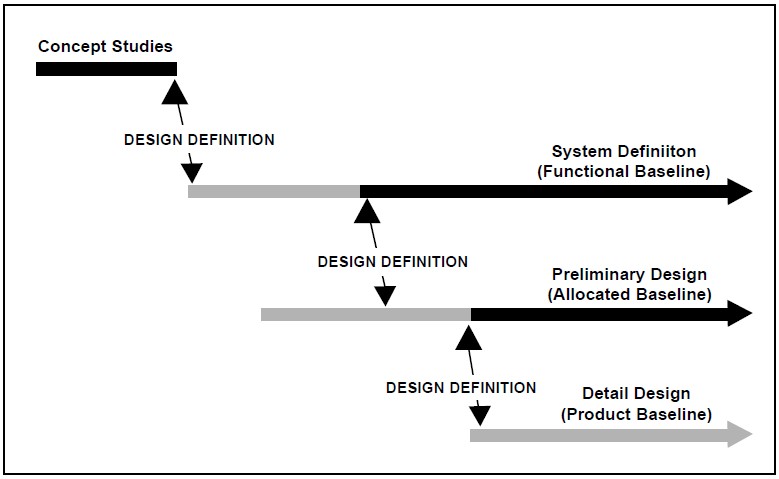

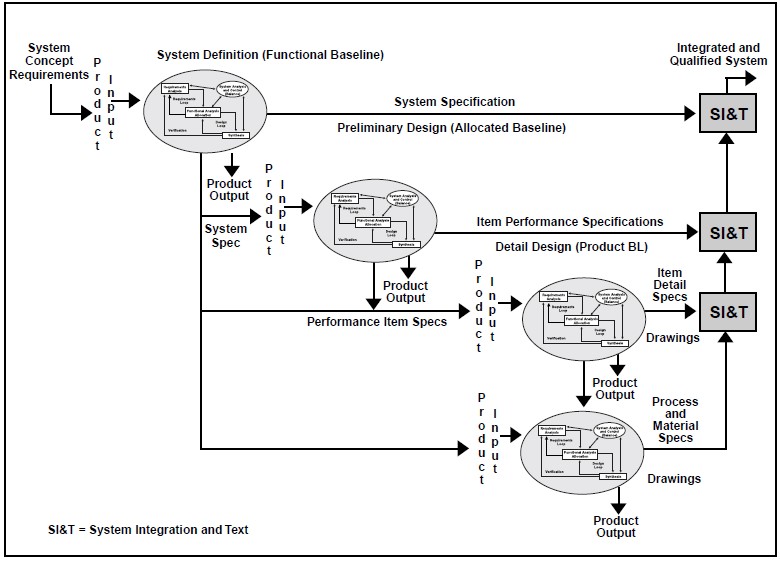

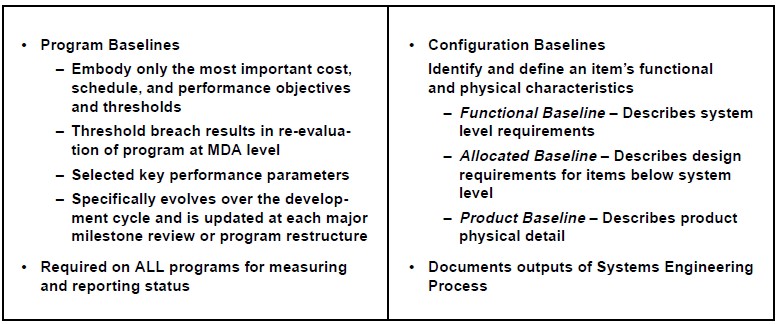

The systems engineering process is applied to each level of system development, one level at a time, to produce these descriptions commonly called configuration baselines. This results in a series of configuration baselines, one at each development level. These baselines become more detailed with each level.

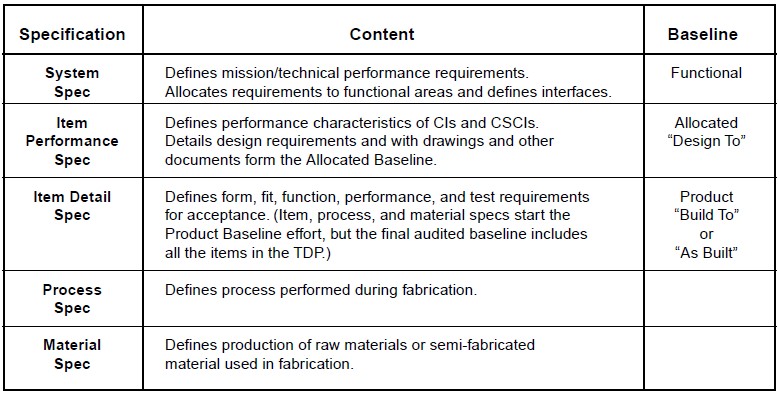

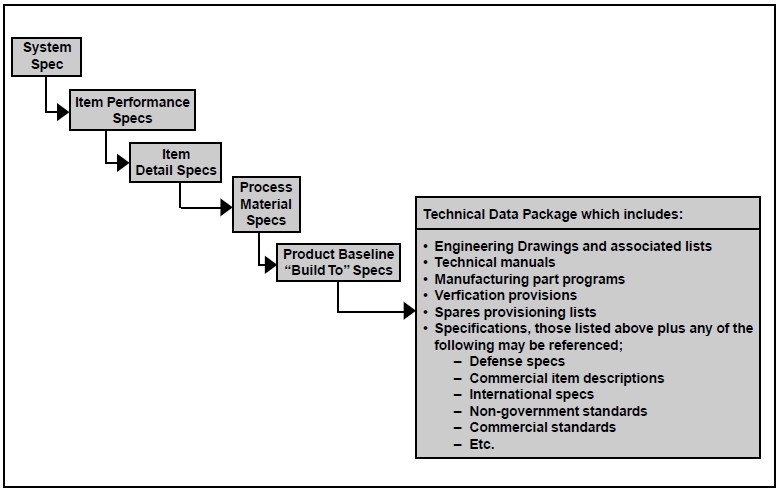

In the Department of Defense (DoD) the configuration baselines are called the functional baseline for the system-level description, the allocated baseline for the subsystem/ component performance descriptions, and the product baseline for the sub-system/component detail descriptions. Figure 1-2 shows the basic relationships between the baselines. The triangles represent baseline control decision points, and are usually referred to as technical re-views or audits.

Levels of Development Considerations

Significant development at any given level in the system hierarchy should not occur until the con-figuration baselines at the higher levels are considered complete, stable, and controlled. Reviews and audits are used to ensure that the baselines are ready for the next level of development. As will be shown in the next chapter, this review and audit process also provides the necessary assessment of system maturity, which supports the DoD Milestone decision process.

1.4 THE SYSTEMS ENGINEERING PROCESS

The systems engineering process is a top-down comprehensive, iterative and recursive problem solving process, applied sequentially through all stages of development, that is used to:

- Transform needs and requirements into a set of system product and process descriptions (adding value and more detail with each level of development),

- Generate information for decision makers, and

- Provide input for the next level of development.

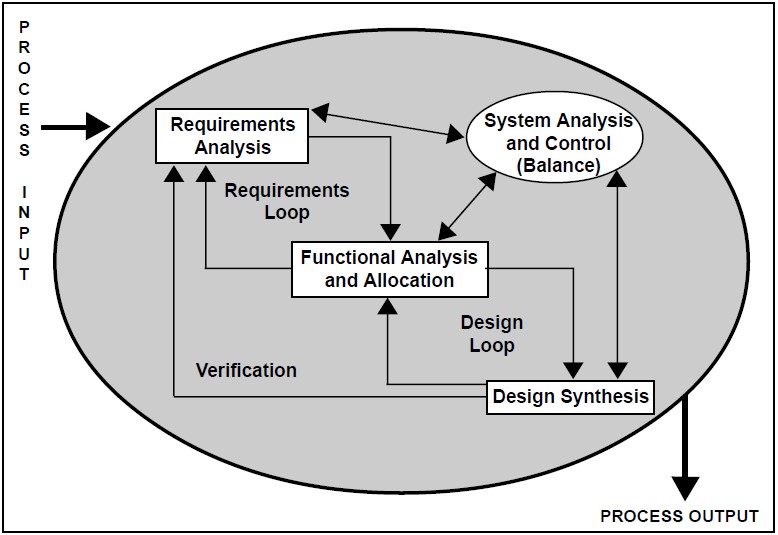

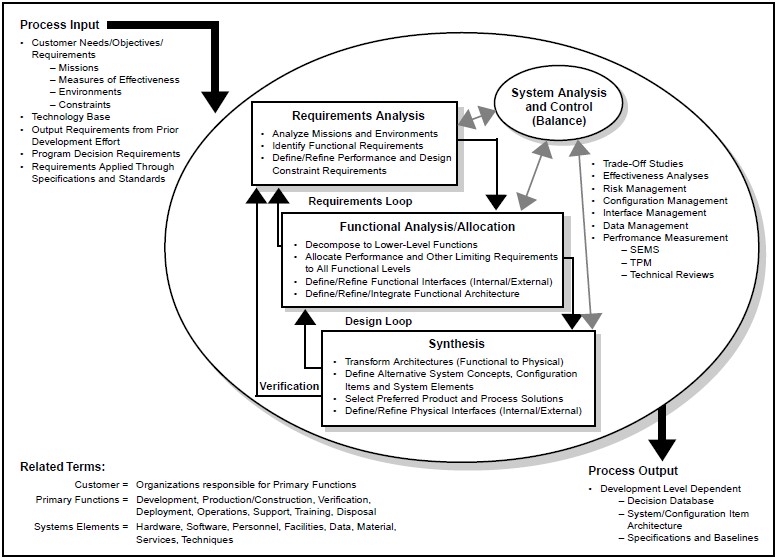

As illustrated by Figure 1-3, the fundamental systems engineering activities are Requirements Analysis, Functional Analysis and Allocation, and Design Synthesis—all balanced by techniques and tools collectively called System Analysis and Control. Systems engineering controls are used to track decisions and requirements, maintain technical baselines, manage interfaces, manage risks, track cost and schedule, track technical performance, verify requirements are met, and review/audit the progress.

During the systems engineering process architectures are generated to better describe and under-stand the system. The word “architecture” is used in various contexts in the general field of engineering. It is used as a general description of how the subsystems join together to form the system. It can also be a detailed description of an aspect of a system: for example, the Operational, System, and Technical Architectures used in Command, Control, Communications, Computers, Intelligence, Surveillance, and Reconnaissance (C4ISR), and software intensive developments. However, Systems Engineering Management as developed in DoD recognizes three universally usable architectures that describe important aspects of the system: functional, physical, and system architectures. This course will focus on these architectures as necessary components of the systems engineering process.

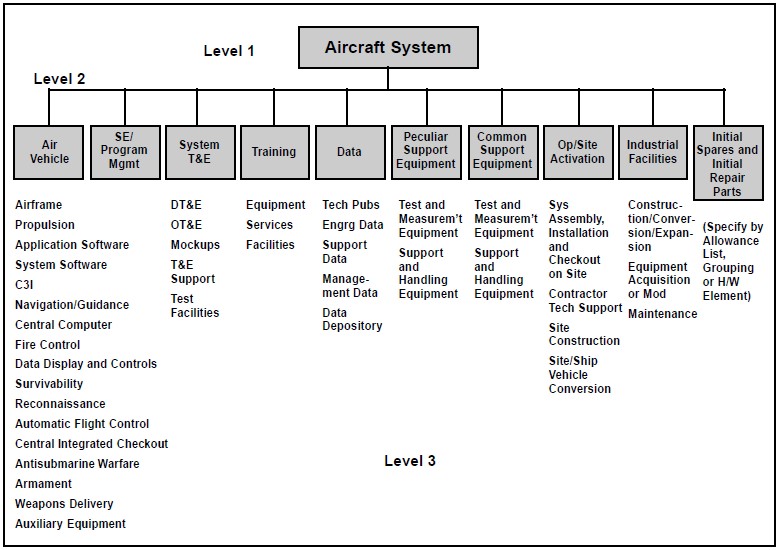

The Functional Architecture identifies and structures the allocated functional and performance requirements. The Physical Architecture depicts the system product by showing how it is broken down into subsystems and components. The System Architecture identifies all the products (including enabling products) that are necessary to support the system and, by implication, the processes necessary for development, production/construction, deployment, operations, support, disposal, training, and verification.

Life Cycle Integration

Life cycle integration is achieved through integrated development—that is, concurrent consideration of all life cycle needs during the development process. DoD policy requires integrated development, called Integrated Product and Product Development (IPPD) in DoD, to be practiced at all levels in the acquisition chain of command as will be explained in the chapter on IPPD. Con-current consideration of all life cycle needs can be greatly enhanced through the use of interdisciplinary teams. These teams are often referred to as Integrated Product Teams (IPTs).

The objective of an Integrated Product Team is to:

- Produce a design solution that satisfies initially defined requirements, and

- Communicate that design solution clearly, effectively, and in a timely manner.

Multi-functional, integrated teams:

- Place balanced emphasis on product and process development, and

- Require early involvement of all disciplines appropriate to the team task.

Design-level IPT members are chosen to meet the team objectives and generally have distinctive competence in:

- Technical management (systems engineering),

- Life cycle functional areas (eight primary functions),

- Technical specialty areas, such as safety, risk management, quality, etc., or

- When appropriate, business areas such as finance, cost/budget analysis, and contracting.

Life Cycle Functions

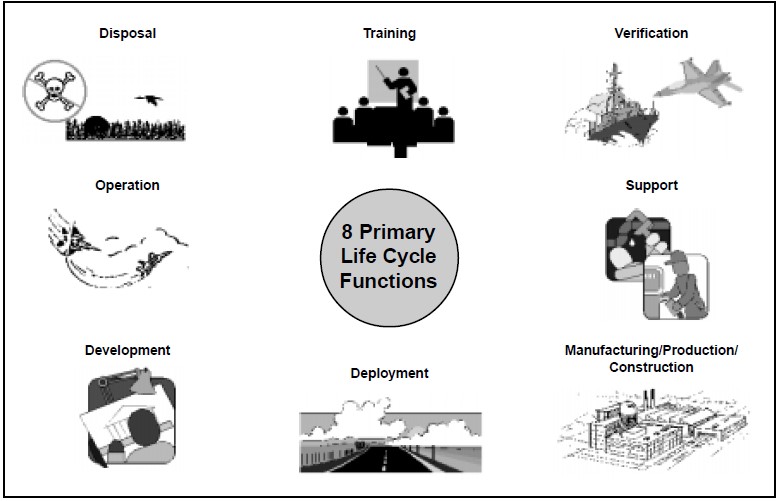

Life cycle functions are the characteristic actions associated with the system life cycle. As illustrated by Figure 1-4, they are development, production and construction, deployment (fielding), operation, support, disposal, training, and verification. These activities cover the “cradle to grave” life cycle process and are associated with major functional groups that provide essential support to the life cycle process. These key life cycle functions are commonly referred to as the eight primary functions of systems engineering.

The customers of the systems engineer perform the life-cycle functions. The system user’s needs are emphasized because their needs generate the requirement for the system, but it must be remembered that all of the life-cycle functional areas generate requirements for the systems engineering process once the user has established the basic need. Those that perform the primary functions also provide life-cycle representation in design-level integrated teams.

Primary Function Definitions

Development includes the activities required to evolve the system from customer needs to product or process solutions.

Manufacturing/Production/Construction includes the fabrication of engineering test models and “brass boards,” low rate initial production, full-rate production of systems and end items, or the construction of large or unique systems or sub-systems.

Deployment (Fielding) includes the activities necessary to initially deliver, transport, receive, process, assemble, install, checkout, train, operate, house, store, or field the system to achieve full operational capability.

Operation is the user function and includes activities necessary to satisfy defined operational objectives and tasks in peacetime and wartime environments.

Support includes the activities necessary to pro-vide operations support, maintenance, logistics, and material management.

Disposal includes the activities necessary to ensure that the disposal of decommissioned, destroyed, or irreparable system components meets all applicable regulations and directives.

Training includes the activities necessary to achieve and maintain the knowledge and skill levels necessary to efficiently and effectively perform operations and support functions.

Verification includes the activities necessary to evaluate progress and effectiveness of evolving system products and processes, and to measure specification compliance.

Systems Engineering Considerations

Systems engineering is a standardized, disciplined management process for development of system solutions that provides a constant approach to system development in an environment of change and uncertainty. It also provides for simultaneous product and process development, as well as a common basis for communication.

Systems engineering ensures that the correct technical tasks get done during development through planning, tracking, and coordinating. Responsibilities of systems engineers include:

- Development of a total system design solution that balances cost, schedule, performance, and risk,

- Development and tracking of technical information needed for decision making,

- Verification that technical solutions satisfy customer requirements,

- Development of a system that can be produced economically and supported throughout the life cycle,

- Development and monitoring of internal and external interface compatibility of the system and subsystems using an open systems approach,

- Establishment of baselines and configuration control, and

- Proper focus and structure for system and major sub-system level design IPTs.

1.5 GUIDANCE

DoD 5000.2-R establishes two fundamental requirements for program management:

- It requires that an Integrated Product and Process approach be taken to design wherever practicable, and

- It requires that a disciplined systems engineering process be used to translate operational needs and/or requirements into a system solution.

Tailoring the Process

System engineering is applied during all acquisition and support phases for large- and small-scale systems, new developments or product improvements, and single and multiple procurements. The process must be tailored for different needs and/or requirements. Tailoring considerations include system size and complexity, level of system definition detail, scenarios and missions, constraints and requirements, technology base, major risk factors, and organizational best practices and strengths.

For example, systems engineering of software should follow the basic systems engineering approach as presented in this course. However, it must be tailored to accommodate the software development environment, and the unique progress tracking and verification problems software development entails. In a like manner, all technology domains are expected to bring their own unique needs to the process.

This course provides a conceptual-level description of systems engineering management. The specific techniques, nomenclature, and recommended methods are not meant to be prescriptive. Technical managers must tailor their systems engineering planning to meet their particular requirements and constraints, environment, technical domain, and schedule/budget situation.

However, the basic time-proven concepts inherent in the systems engineering approach must be retained to provide continuity and control. For com-plex system designs, a full and documented understanding of what the system must do should precede development of component performance descriptions, which should precede component detail descriptions. Though some parts of the system may be dictated as a constraint or interface, in general, solving the design problem should start with analyzing the requirements and determining what the system has to do before physical alternatives are chosen. Configurations must be controlled and risk must be managed.

Tailoring of this process has to be done carefully to avoid the introduction of substantial unseen risk and uncertainty. Without the control, coordination, and traceability of systems engineering, an environment of uncertainty results which will lead to surprises. Experience has shown that these surprises almost invariably lead to significant impacts to cost and schedule. Tailored processes that reflect the general conceptual approach of this course have been developed and adopted by professional societies, academia, industry associations, government agencies, and major companies.

2: Systems Engineering Management in DOD

2.1 INTRODUCTION

The DoD acquisition process has its foundation in federal policy and public law. The development, acquisition, and operation of military systems is governed by a multitude of public laws, formal DoD directives, instructions and manuals, numerous Service and Component regulations, and many inter-service and international agreements.

Managing the development and fielding of military systems requires three basic activities: technical management, business management, and contract management. As described in this course, systems engineering management is the technical management component of DoD acquisition management.

The acquisition process runs parallel to the requirements generation process and the budgeting process (Planning, Programming, and Budgeting System.) User requirements tend to be event driven by threat. The budgeting process is date driven by constraints of the Congressional calendar. Systems Engineering Management bridges these processes and must resolve the dichotomy of event driven needs, event driven technology development, and a calendar driven budget.

Direction and Guidance

The Office of Management and Budget (OMB) provides top-level guidance for planning, budgeting, and acquisition in OMB Circular A-11, Part 3, and the Supplemental Capital Programming Guide: Planning, Budgeting, and Acquisition of Capital Assets, July 1997. These documents establish the broad responsibilities and ground rules to be followed in funding and acquiring major assets. The departments of the executive branch of government are then expected to draft their own guidance consistent with the guidelines established. The principal guidance for defense system acquisitions is the DoD 5000 series of directives and regulations. These documents reflect the actions required of DoD acquisition managers to:

- Translate operational needs into stable, affordable programs,

- Acquire quality products, and

- Organize for efficiency and effectiveness.

2.2 RECENT CHANGES

The DoD 5000 series documents were revised in 2000 to make the process more flexible, enabling the delivery of advanced technology to warfighters more rapidly and at reduced total ownership cost. The new process encourages multiple entry points, depending on the maturity of the fundamental technologies involved, and the use of evolutionary methods to define and develop systems. This encourages a tailored approach to acquisition and engineering management, but it does not alter the basic logic of the underlying systems engineering process.

2.3 ACQUISITION LIFE CYCLE

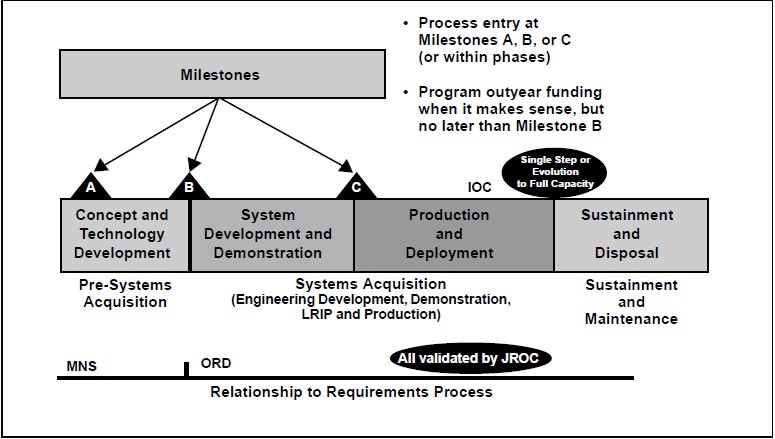

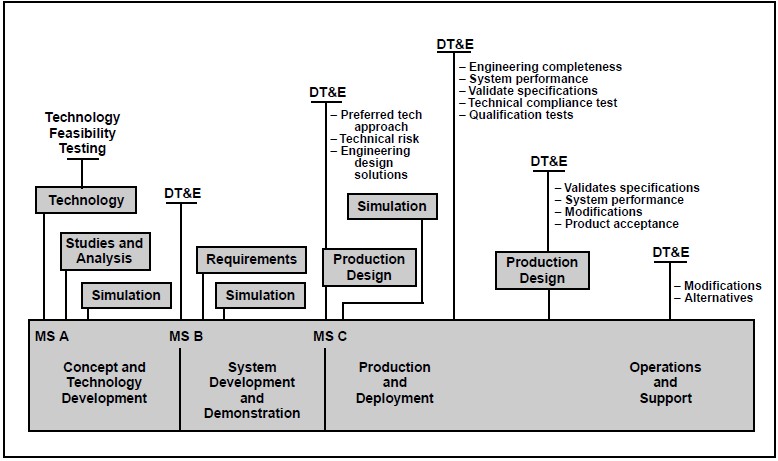

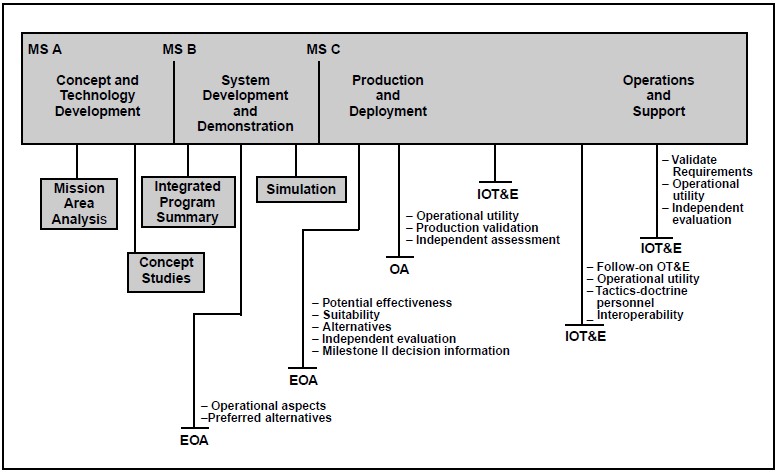

The revised acquisition process for major defense systems is shown in Figure 2-1. The process is defined by a series of phases during which technology is defined and matured into viable concepts, which are subsequently developed and readied for production, after which the systems produced are supported in the field.

The process allows for a given system to enter the process at any of the development phases. For ex-ample, a system using unproven technology would enter at the beginning stages of the process and would proceed through a lengthy period of technology maturation, while a system based on mature and proven technologies might enter directly into engineering development or, conceivably, even production. The process itself (Figure 2-1) includes four phases of development. The first, Concept and Technology Development, is intended to explore alternative concepts based on assessments of operational needs, technology readiness, risk, and affordability. Entry into this phase does not imply that DoD has committed to a new acquisition program; rather, it is the initiation of a process to determine whether or not a need (typically described in a Mission Need Statement (MNS)) can be met at reasonable levels of technical risk and at affordable costs. The decision to enter into the Concept and Technology Development phase is made formally at the Milestone A forum.

The Concept and Technology Development phase begins with concept exploration. During this stage, concept studies are undertaken to define alternative concepts and to provide information about capability and risk that would permit an objective comparison of competing concepts. A decision review is held after completion of the concept exploration activities. The purpose of this review is to determine whether further technology development is required, or whether the system is ready to enter into system acquisition. If the key technologies involved are reasonably mature and have al-ready been demonstrated, the Milestone Decision Authority (MDA) may agree to allow the system to proceed into system acquisition; if not, the system may be directed into a component advanced development stage. (See Supplement A to this chapter for a definition of Technology Readiness levels.) During this stage, system architecture definition will continue and key technologies will be demonstrated in order to ensure that technical and cost risks are understood and are at acceptable levels prior to entering acquisition. In any event, the Concept and Technology Development phase ends with a defined system architecture supported by technologies that are at acceptable levels of maturity to justify entry into system acquisition.

Formal system acquisition begins with a Milestone B decision. The decision is based on an integrated assessment of technology maturity, user requirements, and funding. A successful Milestone B is followed by the System Development and Demonstration phase. This phase could be entered directly as a result of a technological opportunity and urgent user need, as well as having come through concept and technology development. The System Development and Demonstration phase consists of two stages of development, system integration and system demonstration. Depending upon the maturity level of the system, it could enter at either stage, or the stages could be combined. This is the phase during which the technologies, components and subsystems defined earlier are first integrated at the system level, and then demonstrated and tested. If the system has never been integrated into a complete system, it will enter this phase at the system integration stage. When sub-systems have been integrated, prototypes demonstrated, and risks are considered acceptable, the program will normally enter the system demonstration stage following an interim review by the MDA to ensure readiness. The system demonstration stage is intended to demonstrate that the system has operational utility consistent with the operational requirements. Engineering demonstration models are developed and system level development testing and operational assessments are per-formed to ensure that the system performs as required. These demonstrations are to be conducted in environments that represent the eventual operational environments intended. Once a system has been demonstrated in an operationally relevant environment, it may enter the Production and Deployment phase.

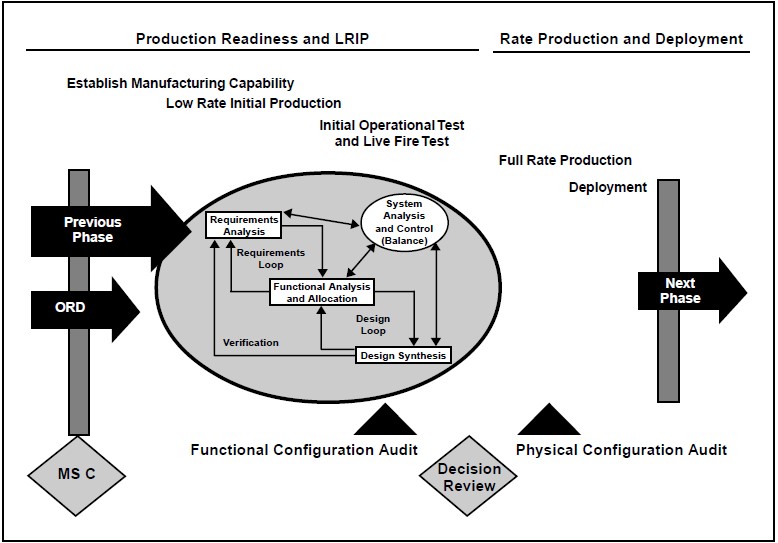

The Production and Deployment phase consists of two stages: production readiness and low rate initial production (LRIP), and rate production and deployment. The decision forum for entry into this phase is the Milestone C event. Again, the fundamental issue as to where a program enters the process is a function of technology maturity, so the possibility exists that a system could enter directly into this phase if it were sufficiently mature, for example, a commercial product to be produced for defense applications. However the entry is made—directly or through the maturation process described, the production readiness and LRIP stage is where initial operational test, live fire test, and low rate initial production are conducted. Upon completion of the LRIP stage and following a favorable Beyond LRIP test report, the system enters the rate production and deployment stage during which the item is produced and deployed to the user. As the system is produced and deployed, the final phase, Sustainment and Disposal, begins.

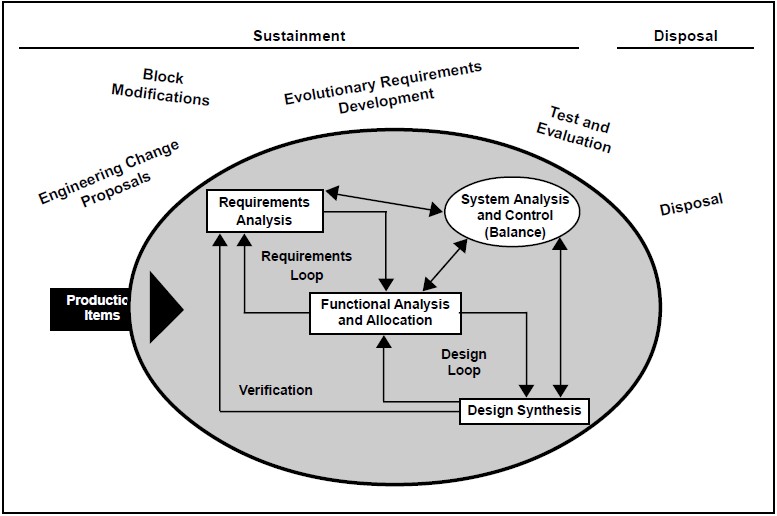

The last, and longest, phase is the Sustainment and Disposal phase of the program. During this phase all necessary activities are accomplished to maintain and sustain the system in the field in the most cost-effective manner possible. The scope of activities is broad and includes everything from maintenance and supply to safety, health, and environmental management. This period may also include transition from contractor to organic sup-port, if appropriate. During this phase, modifications and product improvements are usually implemented to update and maintain the required levels of operational capability as technologies and threat systems evolve. At the end of the system service life it is disposed of in accordance with applicable classified and environmental laws, regulations, and directives. Disposal activities also include recycling, material recovery, salvage of reutilization, and disposal of by-products from development and production.

The key to this model of the acquisition process is that programs have the flexibility to enter at any of the first three phases described. The decision as to where the program should enter the process is primarily a function of user needs and technology maturity. The MDA makes the decision for the program in question. Program managers are encouraged to work with their users to develop evolutionary acquisition strategies that will permit deliveries of usable capabilities in as short a time-frame as possible, with improvements and enhancements added as needed through continuing definition of requirements and development activities to support the evolving needs.

2.4 SYSTEMS ENGINEERING IN ACQUISITION

As required by DoD 5000.2-R, the systems engineering process shall:

- Transform operational needs and requirements into an integrated system design solution through concurrent consideration of all life-cycle needs (i.e., development, manufacturing, test and evaluation, verification, deployment, operations, support, training and disposal).

- Ensure the compatibility, interoperability and integration of all functional and physical inter-faces and ensure that system definition and design reflect the requirements for all system elements: hardware, software, facilities, people, and data; and

- Characterize and manage technical risks.

- Apply scientific and engineering principles to identify security vulnerabilities and to minimize or contain associated information assurance and force protection risks.

These objectives are accomplished with use of the management concepts and techniques described in the chapters which follow in this course. The application of systems engineering management coincides with acquisition phasing. In order to support milestone decisions, major technical reviews are conducted to evaluate system design maturity.

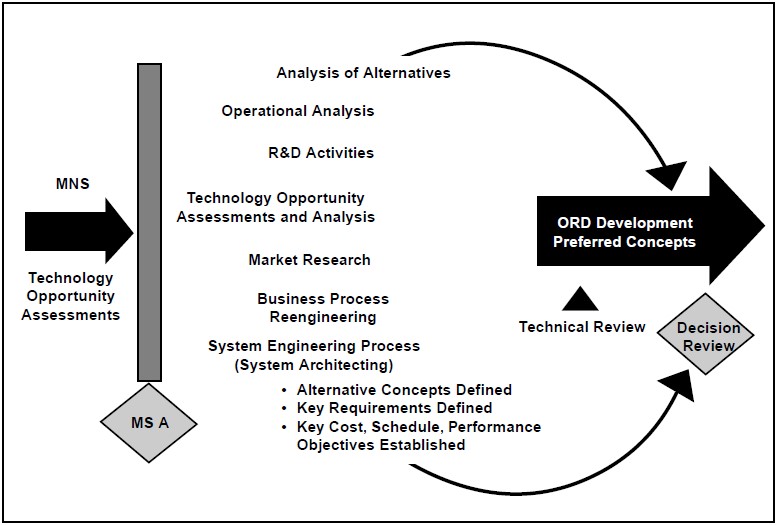

Concept and Technology Development

The Concept and Technology Development phase consists of two pre-acquisition stages of development. The first, Concept Exploration, is represented in Figure 2-2. The exploration of concepts is usually accomplished through multiple short-term studies. Development of these studies is expected to employ various techniques including the systems engineering process that translates inputs into viable concept architectures whose functionality can be traced to the requirements. In addition, market surveys, Business Process Reengineering activities, operational analysis, and trade studies support the process.

The primary inputs to these activities include requirements, in form of the MNS, assessments of technology opportunities and status, and the out-puts from any efforts undertaken to explore potential solutions. When the contractor studies are complete, a specific concept to be pursued is selected based on a integrated assessment of technical performance; technical, schedule and cost risk; as well as other relevant factors. A decision review is then held to evaluate the concept recommended and the state of technology upon which the concept depends. The MDA then makes a decision as to whether the concept development work needs to be extended or redirected, or whether the technology maturity is such that the program can proceed directly to either Mile-stone B (System Development and Demonstration) or Milestone C (Production and Deployment).

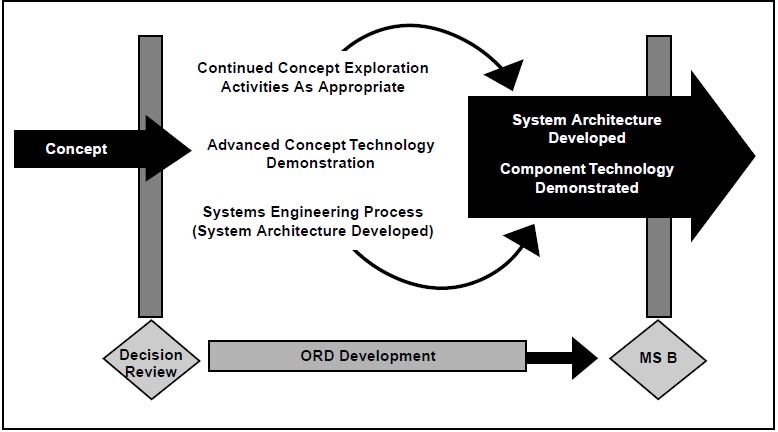

If the details of the concept require definition, i.e., the system has yet to be designed and demonstrated previously, or the system appears to be based on technologies that hold significant risk, then it is likely that the system will proceed to the second stage of the Concept and Technology Development phase. This stage, Component Advanced Development, is represented in Figure 2-3. This is also a pre-acquisition stage of development and is usually characterized by extensive involvement of the DoD Science and Technology (S&T) community. The fundamental objectives of this stage of development are to define a system-level architecture and to accomplish risk-reduction activities as required to establish confidence that the building blocks of the system are sufficiently well-defined, tested and demonstrated to provide confidence that, when integrated into higher level assemblies and subsystems, they will perform reliably.

Development of a system-level architecture entails continuing refinement of system level requirements based on comparative analyses of the system concepts under consideration. It also requires that consideration be given to the role that the system will play in the system of systems of which it will be a part. System level interfaces must be established. Communications and interoperability requirements must be established, data flows defined, and operational concepts refined. Top level planning should also address the strategies that will be employed to maintain the supportability and affordability of the system over its life cycle including the use of common interface standards and open systems architectures. Important design requirements such as interoperability, open systems, and the use of commercial components should also be addressed during this stage of the program.

Risk reduction activities such as modeling and simulation, component testing, bench testing, and man-in-the-loop testing are emphasized as decisions are made regarding the various technologies that must be integrated to form the system. The primary focus at this stage is to ensure that the key technologies that represent the system components (assemblies and sub-systems) are well understood and are mature enough to justify their use in a system design and development effort. The next stage of the life cycle involves engineering development, so research and development (R&D) activities conducted within the science and technology appropriations should be completed during this stage.

System Development and Demonstration

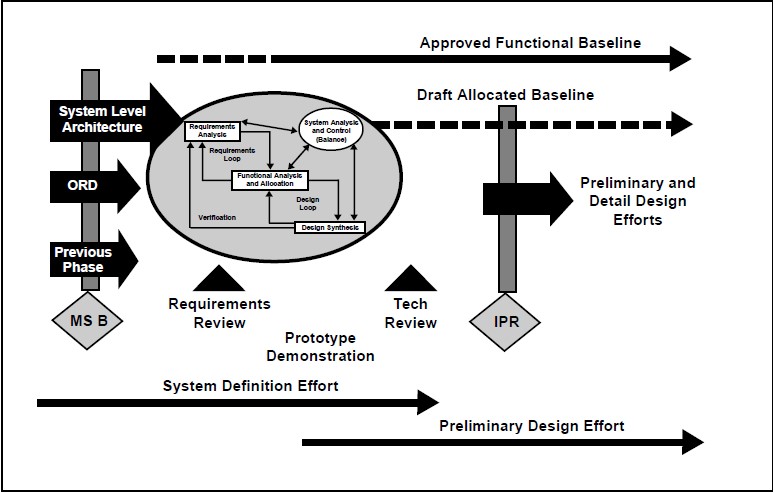

The decision forum for entry into the System Development and Demonstration (SD&D) phase is the Milestone B event. Entry into this phase rep-resents program initiation, the formal beginning of a system acquisition effort. This is the government commitment to pursue the program. Entry requires mature technology, validated requirements, and funding. At this point, the program requirement must be defined by an Operational Requirements Document (ORD). This phase consists of two primary stages, system integration (Figure 2-4) and system demonstration (Figure 2-5).

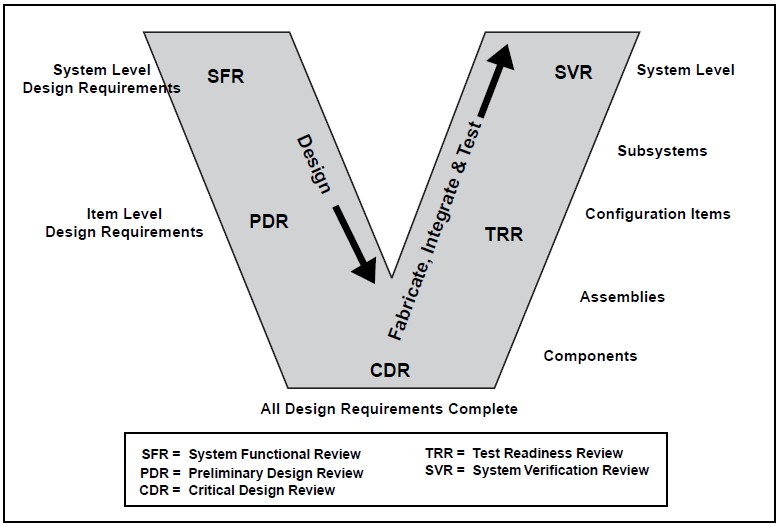

There is no hard and fast guidance that stipulates precisely how the systems engineering process is to intersect with the DoD acquisition process. There are no specified technical events, e.g., DoD designated technical reviews, that are to be accomplished during identified stages of the SD&D phase. However, the results of a SD&D phase should support a production go-ahead decision at Milestone C. That being the case, the process described below reflects a configuration control approach that includes a system level design (functional baseline), final preliminary designs (allocated baselines), and detail designs (initial product baselines). Along with their associated documentation, they represent the systems engineering products developed during SD&D that are most likely needed to appropriately support Milestone C.

System Integration is that stage of SD&D that applies to systems that have yet to achieve system level design maturity as demonstrated by the integration of components at the system level in relevant environments. For an unprecedented system (one not previously defined and developed), this stage will continue the work begun in the component advanced development stage, but the flavor of the effort now becomes oriented to engineering development, rather than the research-oriented efforts that preceded this stage. A formal ORD, technology assessments, and a high-level system architecture have been established. (These will form major inputs to the systems engineering process.) The engineering focus becomes establishment and agreement on system level technical requirements stated such that designs based on those technical requirements will meet the intent of the operational requirements. The system level technical requirements are stabilized and documented in an approved system level requirements specification. In addition, the system-level requirements baseline (functional baseline) is established. This baseline is verified by development and demonstration of prototypes that show that key technologies can be integrated and that associated risks are sufficiently low to justify developing the system.

Program initiation signals the transition from an S&T focus to management by the program office. The R&D community, the users, and the program office may have all been involved in defining the concepts and technologies that will be key to the system development. It is appropriate at this point, therefore, to conduct a thorough requirements analysis and review to ensure that the user, the contractor, and the program office all hold a common view of the requirements and to preserve the lessons learned through the R&D efforts conducted in the earlier phase. The risk at this point can be high, because misunderstandings and errors regarding system-level requirements will flow down to sub-sequent designs and can eventually result in over-runs and even program failure. The contractor will normally use the occasion of the system requirements review early in this stage to set the functional baseline that will govern the flow-down of requirements to lower level items as preliminary designs are elaborated.

The Interim Progress Review held between System Integration and System Demonstration has no established agenda. The agenda is defined by the MDA and can be flexible in its timing and con-tent. Because of the flexibility built into the acquisition process, not all programs will conform to the model presented here. Programs may find themselves in various stages of preliminary design and detailed design as the program passes from one stage of the SD&D phase to the succeeding stage. With these caveats, System Demonstration (Figure 2-5) is the stage of the SD&D phase during which preliminary and detailed designs are elaborated, engineering demonstration models are fabricated, and the system is demonstrated in operationally relevant environments.

System level requirements are flowed down to the lower level items in the architecture and requirements are documented in the item performance specifications, which represent the preliminary design requirements for those items. The item performance specifications and supporting documentation, when finalized, together form the allocated baseline for the system. Design then proceeds toward the elaboration of a detailed design for the product or system. The product baseline is drafted as the design is elaborated. This physical description of the system may change as a result of testing that will follow, but it forms the basis for initial fabrication and demonstration of these items. If the system has been previously designed and fabricated, then, clearly, this process would be curtailed to take advantage of work already completed.

Following the elaboration of the detailed design, components and subsystems are fabricated, integrated, and tested in a bottom-up approach until system level engineering demonstration models are developed. These demonstration models are not, as a rule, production representative systems. Rather, they are system demonstration models, or integrated commercial items, that serve the purpose of enabling the developer to accomplish development testing on the integrated system. These models are often configured specifically to enable testing of critical elements of the system, for example, in the case of an aircraft development, there may be separate engineering demonstration models developed specifically to test the integrated avionics subsystems, while others demonstrate the flying qualities and flight controls subsystems.

For purposes of making decisions relative to progress through the acquisition process, these system-level demonstrations are not intended to be restricted to laboratory test and demonstrations. They are expected to include rigorous demonstrations that the integrated system is capable of per-forming operationally useful tasks under conditions that, while not necessarily equal to the rigor of formal operational testing, represent the eventual environment in which the system must perform. The result of these demonstrations provide the confidence required to convince the decision-maker (MDA) that the system is ready to enter the production phase of the life cycle. This implies that the system has demonstrated not only that technical performance is adequate, but also that the affordability, supportability, and producibility risks are sufficiently low to justify a production decision.

Production and Deployment

Milestone C is the decision forum for entry into the Production and Deployment phase of the program. Like other phases, this phase is also divided into stages of development. Production Readiness and LRIP is the first of these. At this point, system-level demonstrations have been accomplished and the product baseline is defined (although it will be refined as a result of the activities undertaken during this phase). The effort is now directed toward development of the manufacturing capability that will produce the product or system under development. When a manufacturing capability is established, a LRIP effort begins.

The development of a LRIP manufacturing capability has multiple purposes. The items produced are used to proof and refine the production line itself, items produced on this line are used for Initial Operational Test and Evaluation (IOT&E) and Live Fire Test and Evaluation (LFT&E), and this is also the means by which manufacturing rates are ramped upward to the rates intended when manufacturing is fully underway.

Following the completion of formal testing, the submission of required Beyond-LRIP and Live Fire Test reports, and a full-rate production decision by the MDA, the system enters the Rate Production and Deployment stage. After the decision to go to full-rate production, the systems engineering process is used to refine the design to incorporate findings of the independent operational testing, direction from the MDA, and feedback from deployment activities. Once configuration changes have been made and incorporated into production, and the configuration and production is considered stable, Follow-on Operational Test and Evaluation (FOT&E), if required, is typically performed on the stable production system. Test results are used to further refine the production configuration. Once this has been accomplished and production again becomes stable, detailed audits are held to confirm that the Product Baseline documentation correctly describes the system being produced. The Product Baseline is then put under formal configuration control.

As the system is produced, individual items are delivered to the field units that will actually employ and use them in their military missions. Careful coordination and planning is essential to make the deployment as smooth as possible. Integrated planning is absolutely critical to ensure that the training, equipment, and facilities that will be required to support the system, once deployed, are in place as the system is delivered. The systems engineering function during this activity is focused on the integration of the functional specialties to make certain that no critical omission has been made that will render the system less effective than it might otherwise be. Achieving the user’s required initial operational capability (IOC) schedule demands careful attention to the details of the transition at this point. Furthermore, as the system is delivered and operational capability achieved, the system transitions to the Sustainment and Disposal phase of the system life cycle—the longest and most expensive of all phases.

Sustainment and Disposal

There is no separate milestone decision required for a program to enter this phase of the system life cycle. The requirement for the Sustainment phase is implicit in the decision to produce and deploy the system. This phase overlaps the Production phase. Systems Engineering activities in the Sustainment phase are focused on maintaining the system’s performance capability relative to the threat the system faces. If the military threat changes or a technology opportunity emerges, then the system may require modification. These modifications must be approved at an appropriate level for the particular change being considered. The change then drives the initiation of new systems engineering processes, starting the cycle (or parts of it) all over again.

Also, in an evolutionary development environment, there will be a continuing effort to develop and refine additional operational requirements based on the experience of the user with the portion of the system already delivered. As new requirements are generated, a new development cycle begins, with technology demonstrations, risk reduction, system demonstrations and testing—the same cycle just described—all tailored to the specific needs and demands of the technology to be added to the core system already delivered.

The final activity in the system life cycle is Disposal. System engineers plan for and conduct system disposal throughout the life cycle beginning with concept development. System components can require disposal because of decommissioning, their destruction, or irreparable damage. In addition, processes and material used for development, production, operation, or maintenance can raise disposal issues throughout the life cycle. Disposal must be done in accordance with applicable laws, regulations, and directives that are continually changing, usually to require more severe constraints. They mostly relate to security and environment issues that include Recycling, material recovery, salvage, and disposal of by-products from development and production.

Every Development is Different

The process described above is intended to be very flexible in application. There is no “typical” system acquisition. The process is therefore defined to accommodate a wide range of possibilities, from systems that have been proven in commercial applications and are being purchased for military use, to systems that are designed and developed essentially from scratch. The path that the system development takes through the process will depend primarily on the level of maturity of the technology employed. As explained in the preceding discussion, if the system design will rely significantly on the use of proven or commercial items, then process can be adjusted to allow the system to skip phases, or move quickly from stage to stage within phases. If the type of system is well understood within the applicable technical domains, or it is an advanced version of a current well understood system, then the program definition and risk reduction efforts could be adjusted appropriately.

It is the role of the system engineer to advise the program manager of the recommended path that the development should take, outlining the reasons for that recommendation. The decision as to the appropriate path through the process is actually made by the MDA, normally based on the recommendation of the program manager. The process must be tailored to the specific development, both because it is good engineering and because it is DoD policy as part of the Acquisition Reform initiative. But tailoring must done with the intent of preserving the requirements traceability, baseline control, lifecycle focus, maturity tracking, and integration inherent in the systems engineering approach. The validity of tailoring the process should always be a risk management issue. Acquisition Reform issues will be addressed again in Part IV of this text.

[/box]

3: Systems Engineering Process Overview

3.1 THE PROCESS

The Systems Engineering Process (SEP) is a comprehensive, iterative and recursive problem solving process, applied sequentially top-down by integrated teams. It transforms needs and requirements into a set of system product and process descriptions, generate information for decision makers, and provides input for the next level of development. The process is applied sequentially, one level at a time, adding additional detail and definition with each level of development. As shown by Figure 3-1, the process includes: inputs and outputs; requirements analysis; functional analysis and allocation; requirements loop; synthesis; design loop; verification; and system analysis and control.

Systems Engineering Process Inputs

Inputs consist primarily of the customer’s needs, objectives, requirements and project constraints. Inputs can include, but are not restricted to, missions, measures of effectiveness, environments, available technology base, output requirements from prior application of the systems engineering process, program decision requirements, and requirements based on “corporate knowledge.”

Requirements Analysis

The first step of the Systems Engineering Process is to analyze the process inputs. Requirements analysis is used to develop functional and performance requirements; that is, customer requirements are translated into a set of requirements that define what the system must do and how well it must per-form. The systems engineer must ensure that the requirements are understandable, unambiguous, comprehensive, complete, and concise.

Requirements analysis must clarify and define functional requirements and design constraints. Functional requirements define quantity (how many), quality (how good), coverage (how far), time lines (when and how long), and availability (how often). Design constraints define those factors that limit design flexibility, such as: environ-mental conditions or limits; defense against inter-nal or external threats; and contract, customer or regulatory standards.

Functional Analysis/Allocation

Functions are analyzed by decomposing higher-level functions identified through requirements analysis into lower-level functions. The performance requirements associated with the higher level are allocated to lower functions. The result is a description of the product or item in terms of what it does logically and in terms of the performance required. This description is often called the functional architecture of the product or item. Functional analysis and allocation allows for a better understanding of what the system has to do, in what ways it can do it, and to some extent, the priorities and conflicts associated with lower-level functions. It provides information essential to optimizing physical solutions. Key tools in functional analysis and allocation are Functional Flow Block Diagrams, Time Line Analysis, and the Requirements Allocation Sheet.

Requirements Loop

Performance of the functional analysis and allocation results in a better understanding of the requirements and should prompt reconsideration of the requirements analysis. Each function identified should be traceable back to a requirement. This iterative process of revisiting requirements analysis as a result of functional analysis and allocation is referred to as the requirements loop.

Design Synthesis

Design synthesis is the process of defining the product or item in terms of the physical and soft-ware elements which together make up and define the item. The result is often referred to as the physical architecture. Each part must meet at least one functional requirement, and any part may support many functions. The physical architecture is the basic structure for generating the specifications and baselines.

Design Loop

Similar to the requirements loop described above, the design loop is the process of revisiting the functional architecture to verify that the physical design synthesized can perform the required functions at required levels of performance. The design loop permits reconsideration of how the system will perform its mission, and this helps optimize the synthesized design.

Verification

For each application of the system engineering process, the solution will be compared to the requirements. This part of the process is called the verification loop, or more commonly, Verification. Each requirement at each level of development must be verifiable. Baseline documentation developed during the systems engineering process must establish the method of verification for each requirement.

Appropriate methods of verification include examination, demonstration, analysis (including modeling and simulation), and testing. Formal test and evaluation (both developmental and opera-tional) are important contributors to the verification of systems.

Systems Analysis and Control

Systems Analysis and Control include technical management activities required to measure progress, evaluate and select alternatives, and document data and decisions. These activities apply to all steps of the systems engineering process.

System analysis activities include trade-off studies, effectiveness analyses, and design analyses. They evaluate alternative approaches to satisfy technical requirements and program objectives, and provide a rigorous quantitative basis for selecting performance, functional, and design requirements. Tools used to provide input to analysis activities include modeling, simulation, experimentation, and test.

Control activities include risk management, con-figuration management, data management, and performance-based progress measurement including event-based scheduling, Technical Performance Measurement (TPM), and technical reviews.

The purpose of Systems Analysis and Control is to ensure that:

- Solution alternative decisions are made only after evaluating the impact on system effective-ness, life cycle resources, risk, and customer requirements,

- Technical decisions and specification requirements are based on systems engineering outputs,

- Traceability from systems engineering process inputs to outputs is maintained,

- Schedules for development and delivery are mutually supportive,

- Required technical disciplines are integrated into the systems engineering effort,

- Impacts of customer requirements on resulting functional and performance requirements are examined for validity, consistency, desirability, and attainability, and,

- Product and process design requirements are directly traceable to the functional and performance requirements they were designed to fulfill, and vice versa.

Systems Engineering Process Output

Process output is dependent on the level of development. It will include the decision database, the system or configuration item architecture, and the baselines, including specifications, appropriate to the phase of development. In general, it is any data that describes or controls the product configuration or the processes necessary to develop that product.

4: Requirements Analysis

4.1 SYSTEMS ENGINEERING PROCESS INPUTS

The inputs to the process include the customer’s requirements and the project constraints. Requirements relate directly to the performance characteristics of the system being designed. They are the stated life-cycle customer needs and objectives for the system, and they relate to how well the system will work in its intended environment.

Constraints are conditions that exist because of limitations imposed by external interfaces, project support, technology, or life cycle support systems. Constraints bound the development teams’ design opportunities.

Requirements are the primary focus in the systems engineering process because the process’s primary purpose is to transform the requirements into de-signs. The process develops these designs within the constraints. They eventually must be verified to meet both the requirements and constraints.

Types of Requirements

Requirements are categorized in several ways. The following are common categorizations of requirements that relate to technical management:

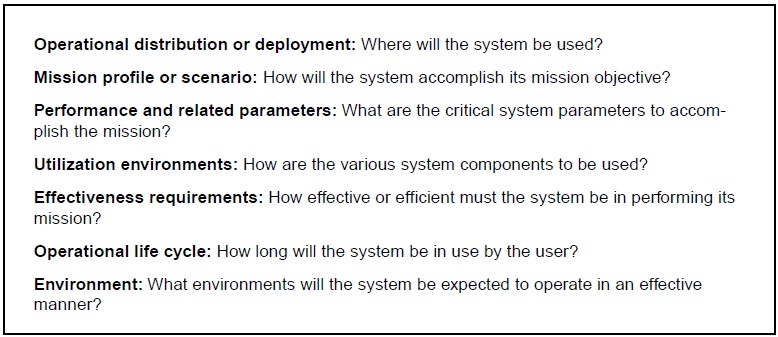

Customer Requirements: Statements of fact and assumptions that define the expectations of the system in terms of mission objectives, environment, constraints, and measures of effectiveness and suitability (MOE/MOS). The customers are those that perform the eight primary functions of systems engineering (Chapter 1), with special emphasis on the operator as the key customer. Operational requirements will define the basic need and, at a minimum, answer the questions posed in Figure 4-1.

Functional Requirements: The necessary task, action or activity that must be accomplished. Func-tional (what has to be done) requirements identified in requirements analysis will be used as the top-level functions for functional analysis.

Performance Requirements: The extent to which a mission or function must be executed; generally measured in terms of quantity, quality, coverage, timeliness or readiness. During requirements analy-sis, performance (how well does it have to be done) requirements will be interactively developed across all identified functions based on system life cycle factors; and characterized in terms of the degree of certainty in their estimate, the degree of criti-cality to system success, and their relationship to other requirements.

Design Requirements: The “build to,” “code to,” and “buy to” requirements for products and “how to execute” requirements for processes expressed in technical data packages and technical manuals.

Derived Requirements: Requirements that are implied or transformed from higher-level require-ment. For example, a requirement for long range or high speed may result in a design requirement for low weight.

Allocated Requirements: A requirement that is established by dividing or otherwise allocating a high-level requirement into multiple lower-level requirements. Example: A 100-pound item that consists of two subsystems might result in weight requirements of 70 pounds and 30 pounds for the two lower-level items.

Attributes of Good Requirements

The attributes of good requirements include the following:

- A requirement must be achievable. It must reflect need or objective for which a solution is technically achievable at costs considered affordable.

- It must be verifiable—that is, not defined by words such as excessive, sufficient, resistant, etc. The expected performance and functional utility must be expressed in a manner that allows verification to be objective, preferably quantitative.

- A requirement must be unambiguous. It must have but one possible meaning.

- It must be complete and contain all mission profiles, operational and maintenance concepts, utilization environments and constraints. All information necessary to understand the customer’s need must be there.

- It must be expressed in terms of need, not solution; that is, it should address the “why” and “what” of the need, not how to do it.

- It must be consistent with other requirements. Conflicts must be resolved up front.

- It must be appropriate for the level of system hierarchy. It should not be too detailed that it constrains solutions for the current level of design. For example, detailed requirements relating to components would not normally be in a system-level specification.

4.2 REQUIREMENTS ANALYSIS

Requirements analysis involves defining customer needs and objectives in the context of planned customer use, environments, and identified system characteristics to determine requirements for system functions. Prior analyses are reviewed and updated, refining mission and environment definitions to support system definition.

Requirements analysis is conducted iteratively with functional analysis to optimize performance requirements for identified functions, and to verify that synthesized solutions can satisfy customer requirements. The purpose of Requirements Analysis is to:

- Refine customer objectives and requirements;

- Define initial performance objectives and refine them into requirements;

- Identify and define constraints that limit solutions; and

- Define functional and performance requirements based on customer provided measures of effectiveness.

In general, Requirements Analysis should result in a clear understanding of:

- Functions: What the system has to do,

- Performance: How well the functions have to be performed,

- Interfaces: Environment in which the system will perform, and

- Other requirements and constraints.

The understandings that come from requirements analysis establish the basis for the functional and physical designs to follow. Good requirements analysis is fundamental to successful design definition.

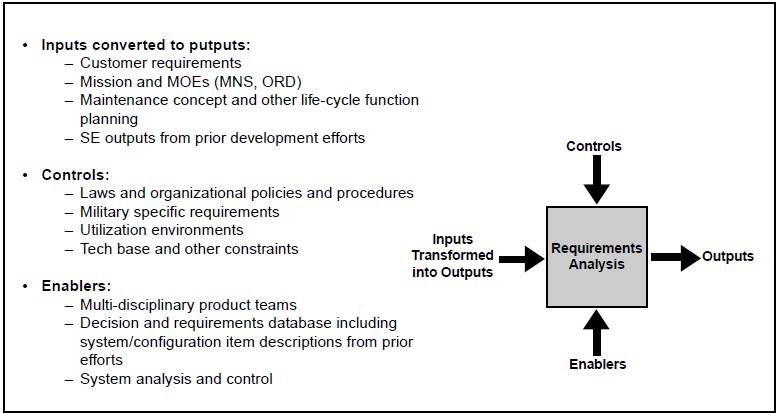

Inputs

Typical inputs include customer needs and objectives, missions, MOE/MOS, environments, key performance parameters (KPPs), technology base, output requirements from prior application of SEP, program decision requirements, and suitability requirements. (See Figure 4-2 for additional considerations.)

Input requirements must be comprehensive and defined for both system products and system processes such as development, manufacturing, verification, deployment, operations, support, training and disposal (eight primary functions).

Role of Integrated Teams

The operator customers have expertise in the operational employment of the product or item being developed. The developers (government and contractor) are not necessarily competent in the operational aspects of the system under development. Typically, the operator’s need is neither clearly nor completely expressed in a way directly usable by developers. It is unlikely that develop-ers will receive a well-defined problem from which they can develop the system specification. Thus, teamwork is necessary to understand the problem and to analyze the need. It is imperative that customers are part of the definition team.

On the other hand, customers often find it easier to describe a system that attempts to solve the prob-lem rather than to describe the problem itself. Although these “solutions” may be workable to some extent, the optimum solution is obtained through a proper technical development effort that properly balances the various customer mis-sion objectives, functions, MOE/MOS, and con-straints. An integrated approach to product and process development will balance the analysis of requirements by providing understanding and accommodation among the eight primary functions.

Requirements Analysis Questions

Requirements Analysis is a process of inquiry and resolution. The following are typical questions that can initiate the thought process:

- What are the reasons behind the system development?

- What are the customer expectations?

- Who are the users and how do they intend to use the product?

- What do the users expect of the product?

- What is their level of expertise?

- With what environmental characteristics must the system comply?

- What are existing and planned interfaces?

- What functions will the system perform, expressed in customer language?

- What are the constraints (hardware, software, economic, procedural) to which the system must comply?

- What will be the final form of the product: such as model, prototype, or mass production?

This list can start the critical, inquisitive outlook necessary to analyze requirements, but it is only the beginning. A tailored process similar to the one at the end of this chapter must be developed to produce the necessary requirements analysis outputs.

4.3 REQUIREMENTS ANALYSIS OUTPUTS

The requirements that result from requirements analysis are typically expressed from one of three perspectives or views. These have been described as the Operational, Functional, and Physical views. All three are necessary and must be coordinated to fully understand the customers’ needs and objectives. All three are documented in the decision database.

Operational View

The Operational View addresses how the system will serve its users. It is useful when establishing requirements of “how well” and “under what condition.” Operational view information should be documented in an operational concept document that identifies:

- Operational need definition,

- System mission analysis,

- Operational sequences,

- Operational environments,

- Conditions/events to which a system must respond,

- Operational constraints on system,

- Mission performance requirements,

- User and maintainer roles (defined by job tasks and skill requirements or constraints),

- Structure of the organizations that will operate, support and maintain the system, and

- Operational interfaces with other systems.

Analyzing requirements requires understanding the operational and other life cycle needs and constraints.

Functional View

The Functional View focuses on WHAT the system must do to produce the required operational behavior. It includes required inputs, outputs, states, and transformation rules. The functional requirements, in combination with the physical requirements shown below, are the primary sources of the requirements that will eventually be reflected in the system specification. Functional View information includes:

- System functions,

- System performance,

– Qualitative — how well

– Quantitative — how much, capacity

– Timeliness — how often - Tasks or actions to be performed,

- Inter-function relationships,

- Hardware and software functional relationships,

- Performance constraints,

- Interface requirements including identification of potential open-system opportunities (potential standards that could promote open systems should be identified),

- Unique hardware or software, and

- Verification requirements (to include inspection, analysis/simulation, demo, and test).

Physical View

The Physical View focuses on HOW the system is constructed. It is key to establishing the physical interfaces among operators and equipment, and technology requirements. Physical View information would normally include:

- Configuration of System:

– Interface descriptions,

– Characteristics of information displays and operator controls,

– Relationships of operators to system/physical equipment, and

– Operator skills and levels required to perform assigned functions. - Characterization of Users:

– Handicaps (special operating environments), and

– Constraints (movement or visual limitations). - System Physical Limitations:

– Physical limitations (capacity, power, size, weight),

– Technology limitations (range, precision, data rates, frequency, language),

– Government Furnished Equipment (GFE), Commercial-Off-the-Shelf (COTS), Nondevelopment Item (NDI), reusability requirements, and

– Necessary or directed standards.

5: Functional Analysis and Allocation

5.1 INTRODUCTION

The purpose of this systems engineering process activity is to transform the functional, performance, interface and other requirements that were identified through requirements analysis into a coherent description of system functions that can be used to guide the Design Synthesis activity that follows. The designer will need to know what the system must do, how well, and what constraints will limit design flexibility.

This is accomplished by arranging functions in logical sequences, decomposing higher-level functions into lower-level functions, and allocating performance from higher- to lower-level functions. The tools used include functional flow block diagrams and timeline analysis; and the product is a functional architecture, i.e., a description of the system—but in terms of functions and performance parameters, rather than a physical description. Functional Analysis and Allocation facilitates traceability from requirements to the solution descriptions that are the outcome of Design Synthesis.

Functions are discrete actions (use action verbs) necessary to achieve the system’s objectives. These functions may be stated explicitly, or they may be derived from stated requirements. The functions will ultimately be performed or accomplished through use of equipment, personnel, facilities, software, or a combination.

5.2 FUNCTIONAL ANALYSIS AND ALLOCATION

Functional and performance requirements at any level in the system are developed from higher-level requirements. Functional Analysis and Allocation is repeated to define successively lower-level functional and performance requirements, thus defining architectures at ever-increasing levels of detail. System requirements are allocated and defined in sufficient detail to provide design and verification criteria to support the integrated system design.

This top-down process of translating system-level requirements into detailed functional and performance design criteria includes:

- Defining the system in functional terms, then decomposing the top-level functions into sub functions. That is, identifying at successively lower levels what actions the system has to do,

- Translating higher-level performance requirements into detailed functional and performance design criteria or constraints. That is, identifying how well the functions have to be performed,

- Identifying and defining all internal and external functional interfaces,

- Identifying functional groupings to minimize and control interfaces (functional partitioning),

- Determining the functional characteristics of existing or directed components in the system and incorporating them in the analysis and allocation,

- Examining all life cycle functions, including the eight primary functions, as appropriate for the specific project,

- Performing trade studies to determine alternative functional approaches to meet requirements, and

- Revisiting the requirements analysis step as necessary to resolve functional issues.

The objective is to identify the functional, performance, and interface design requirements; it is not to design a solution…yet!

Functional Partitioning

Functional partitioning is the process of grouping functions that logically fit with the components likely to be used, and to minimize functional interfaces. Partitioning is performed as part of functional decomposition. It identifies logical groupings of functions that facilitate the use of modular components and open-system designs. Functional partitioning is also useful in understanding how existing equipment or components (including commercial) will function with or within the system.

Requirements Loop

During the performance of the Functional Analysis and Allocation process, it is expected that revisiting the requirements analysis process will be necessary. This is caused by the emergence of functional issues that will require re-examination of the higher-level requirements. Such issues might include directed components or standards that cause functional conflict, identification of a revised approach to functional sequencing, or, most likely, a conflict caused by mutually incompatible requirements.

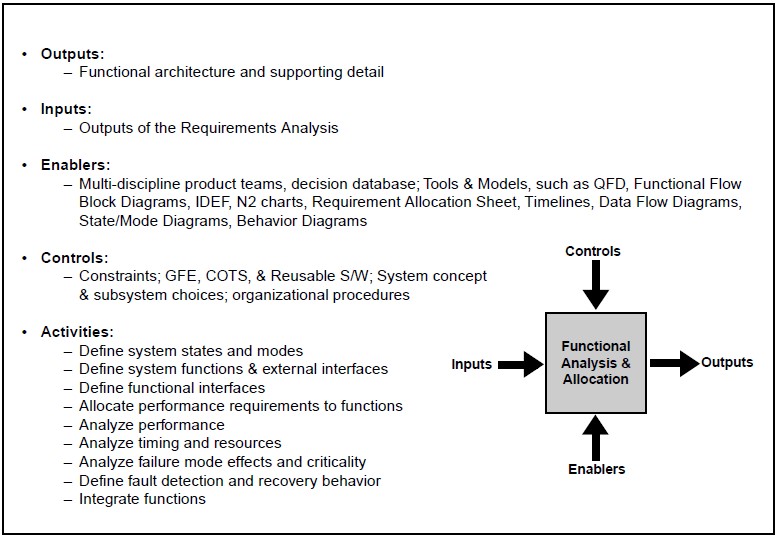

Figure 5-1 gives an overview of the basic parameters of Functional Analysis and Allocation. The output of the process is the functional architecture. In its most basic form, the functional architecture is a simple hierarchical decomposition of the functions with associated performance requirements. As the architecture definition is refined and made more specific with the performance of the activities listed in Figure 5-1, the functional architecture becomes more detailed and comprehensive. These activities provide a functional architecture with sufficient detail to support the Design Synthesis. They are performed with the aid of traditional tools that structure the effort and pro-vide documentation for traceability. There are many tools available. The following are traditional tools that represent and explain the primary tasks of Functional Analysis and Allocation (several of these are defined and illustrated beginning on page 49):

- Functional flow block diagrams that define task sequences and relationships,

- IDEF0 diagrams that define process and data flows,

- Timeline analyses that define the time sequence of time critical functions, and

- Requirements allocation sheets that identify allocated performance and establish traceability of performance requirements.

5.3 FUNCTIONAL ARCHITECTURE

The functional architecture is a top-down decom-position of system functional and performance requirements. The architecture will show not only the functions that have to be performed, but also the logical sequencing of the functions and performance requirements associated with the functions. It also includes the functional description of existing and government-furnished items to be used in the system. This may require reverse engineering of these existing components.

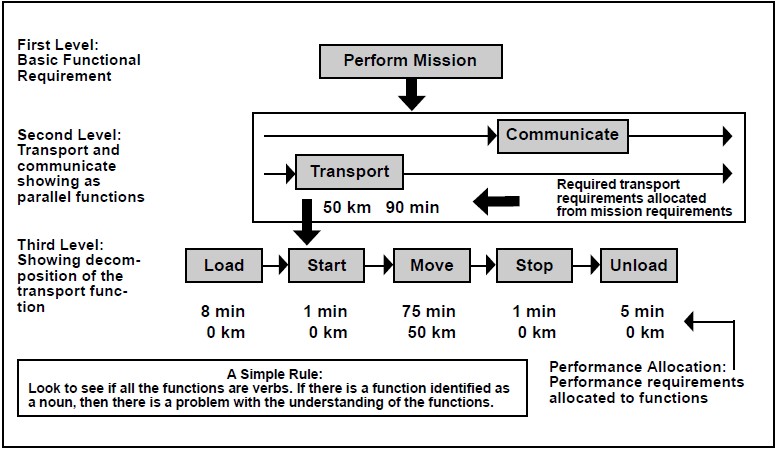

The functional architecture produced by the Functional Analysis and Allocation process is the detailed package of documentation developed to analyze the functions and allocate performance requirements. It includes the functional flow block diagrams, timeline sheets, requirements allocation sheets, IDEF0 diagrams, and all other documentation developed to describe the functional characteristics of the system. However, there is a basic logic to the functional architecture, which in its preliminary form is presented in the example of Figure 5-2. The Functional Analysis and Allocation process would normally begin with the IPT drafting such a basic version of the architecture. This would generally give the IPT an understanding of the scope and direction of the effort.

Functional Architecture Example

The Marine Corps has a requirement to transport troops in squad-level units over a distance of 50 kilometers. Troops must be transported within 90 minutes from the time of arrival of the transport system. Constant communication is required during the transportation of troops. Figure 5-2 illustrates a preliminary functional architecture for this simple requirement.

6: Design Synthesis

6.1 DESIGN DEVELOPMENT

Design Synthesis is the process by which concepts or designs are developed based on the functional descriptions that are the products of Functional Analysis and Allocation. Design synthesis is a creative activity that develops a physical architecture (a set of product, system, and/or software elements) capable of performing the required functions within the limits of the performance parameters pre-scribed. Since there may be several hardware and/or software architectures developed to satisfy a given set of functional and performance requirements, synthesis sets the stage for trade studies to select the best among the candidate architectures. The objective of design synthesis is to combine and restructure hardware and software components in such a way as to achieve a design solution capable of satisfying the stated requirements. During concept development, synthesis produces system concepts and establishes basic relation-ships among the subsystems. During preliminary and detailed design, subsystem and component descriptions are elaborated, and detailed interfaces between all system components are defined.

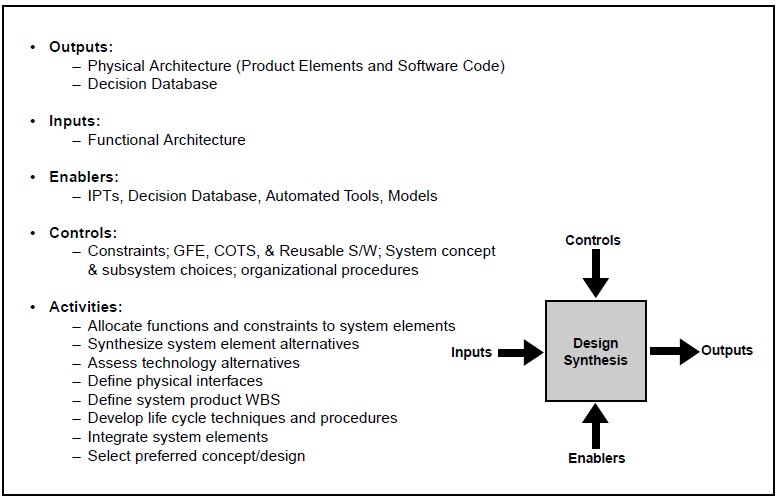

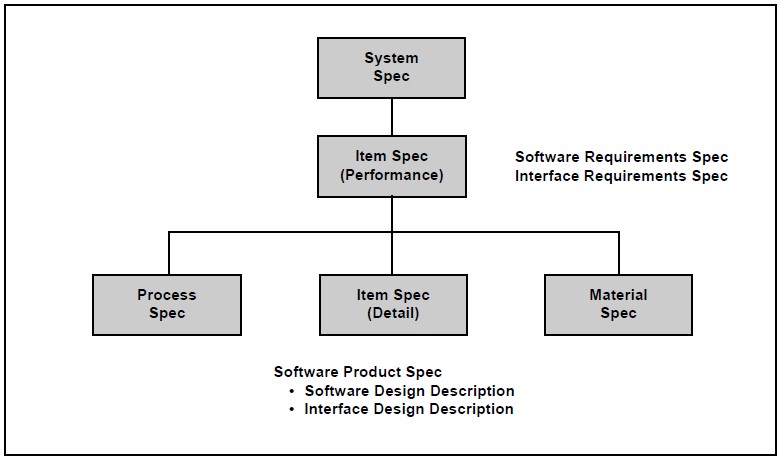

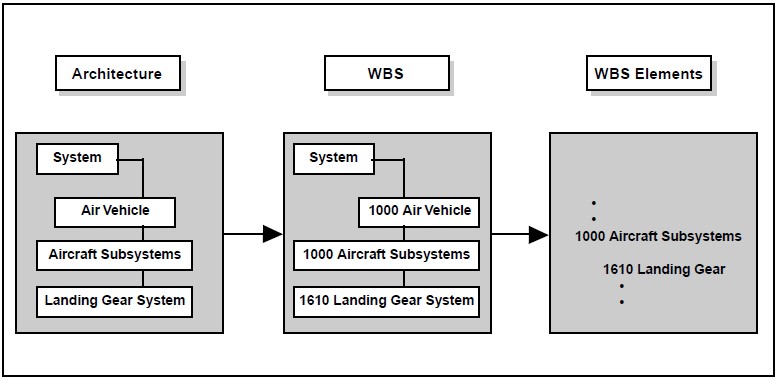

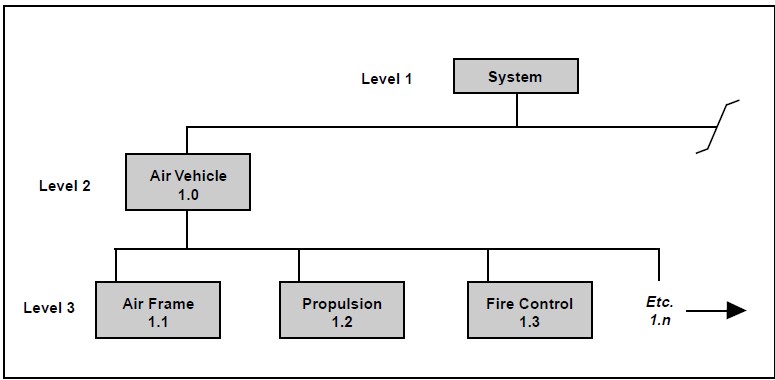

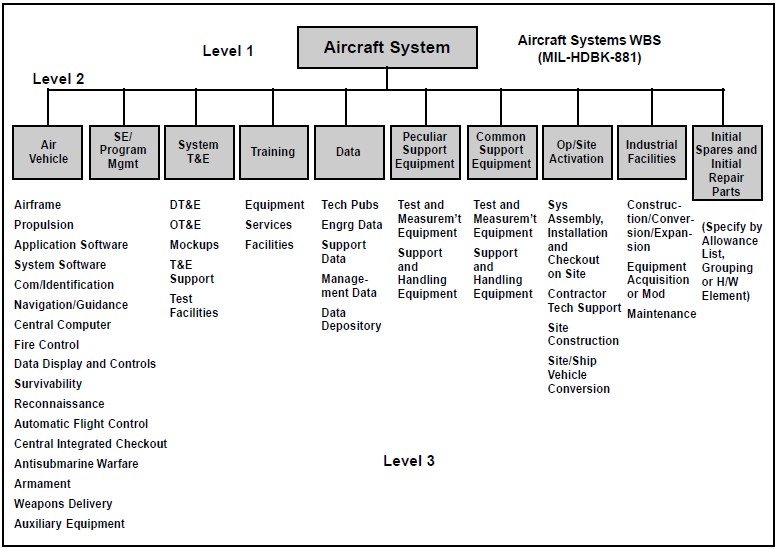

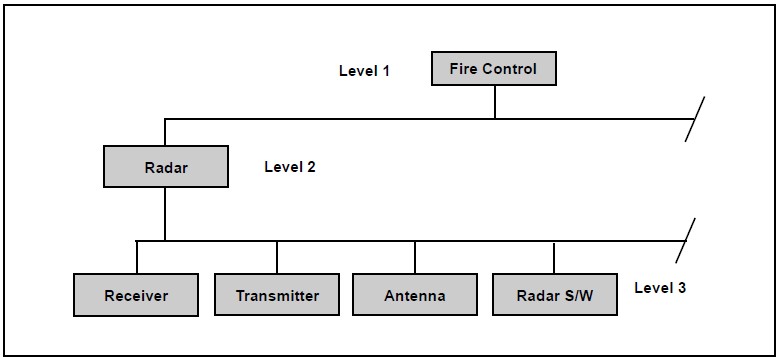

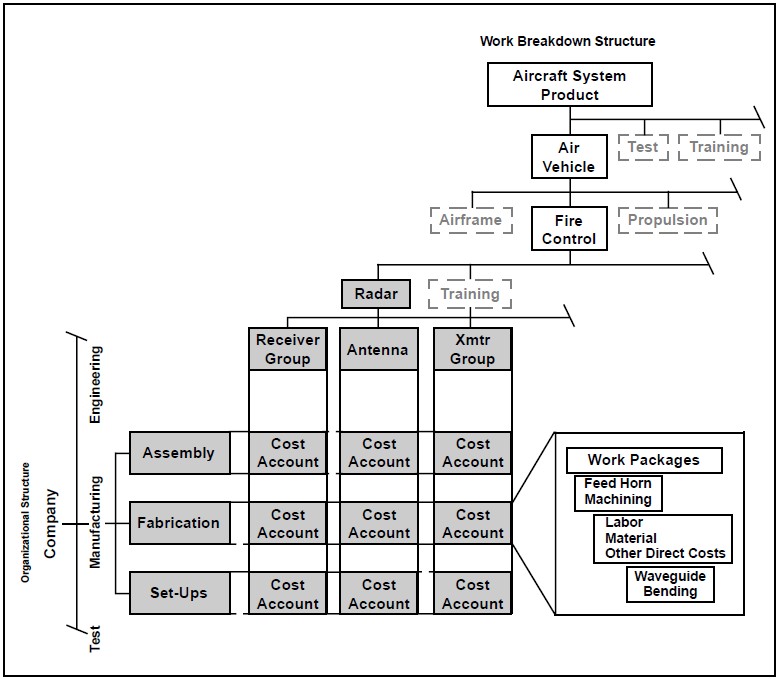

The physical architecture forms the basis for design definition documentation, such as, specifications, baselines, and work breakdown structures (WBS). Figure 6-1 gives an overview of the basic parameters of the synthesis process.

Characteristics

Physical architecture is a traditional term. Despite the name, it includes software elements as well as hardware elements. Among the characteristics of the physical architecture (the primary output of Design Synthesis) are the following:

- The correlation with functional analysis requires that each physical or software component meets at least one (or part of one) functional requirement, though any component can meet more than one requirement,

- The architecture is justified by trade studies and effectiveness analyses,

- A product WBS is developed from the physical architecture,

- Metrics are developed to track progress among KPPs, and

- All supporting information is documented in a database.

Modular Designs

Modular designs are formed by grouping components that perform a single independent function or single logical task; have single entry and exit points; and are separately testable. Grouping related functions facilitates the search for modular design solutions and furthermore increases the possibility that open-systems approaches can be used in the product architecture.

Desirable attributes of the modular units include low coupling, high cohesion, and low connectivity. Coupling between modules is a measure of their interdependence, or the amount of information shared between two modules. Decoupling modules eases development risks and makes later modifications easier to implement. Cohesion (also called binding) is the similarity of tasks performed within the module. High cohesion is desirable because it allows for use of identical or like (family or series) components, or for use of a single component to perform multiple functions. Connectivity refers to the relationship of internal elements within one module to internal elements within another module. High connectivity is undesirable in that it creates complex interfaces that may impede design, development, and testing.

Design Loop

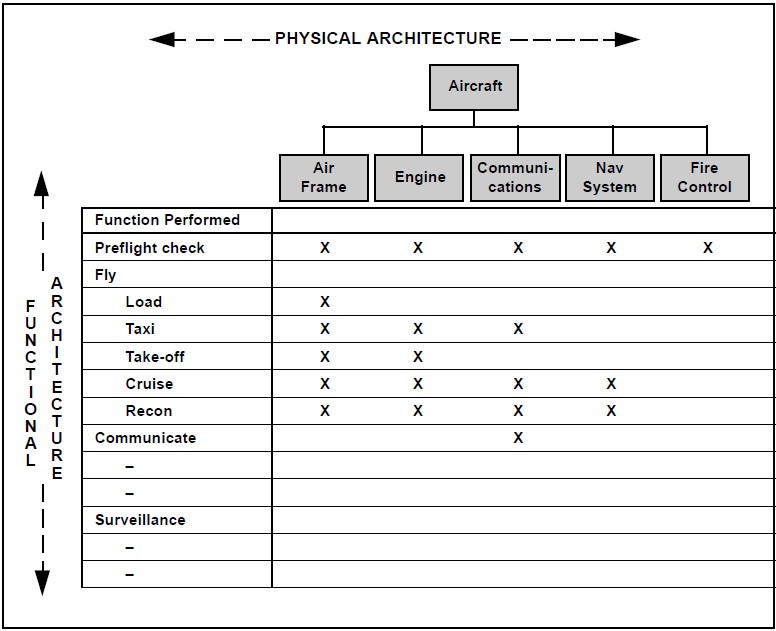

The design loop involves revisiting the functional architecture to verify that the physical architecture developed is consistent with the functional and performance requirements. It is a mapping between the functional and physical architectures. Figure 6-2 shows an example of a simple physical architecture and how it relates to the functional architecture. During design synthesis, re-evaluation of the functional analysis may be caused by the discovery of design issues that require re-examination of the initial decomposition, performance allocation, or even the higher-level requirements. These issues might include identification of a promising physical solution or open-system opportunities that have different functional characteristics than those foreseen by the initial functional architecture requirements.

6.2 SYNTHESIS TOOLS

During synthesis, various analytical, engineering, and modeling tools are used to support and document the design effort. Analytical devices such as trade studies support decisions to optimize physical solutions. Requirements Allocation Sheets (RAS) provide traceability to the functional and performance requirements. Simple descriptions like the Concept Description Sheet (CDS) help visualize and communicate the system concept. Logic models, such as the Schematic Block Diagram (SBD), establish the design and the interrelation-ships within the system.

Automated engineering management tools such as Computer-Aided Design (CAD), Computer-Aided-Systems Engineering (CASE), and the Computer-Aided-Engineering (CAE) can help organize, coordinate and document the design effort. CAD generates detailed documentation describing the product design including SBDs, detailed drawings, three dimensional and solid drawings, and it tracks some technical performance measurements. CAD can provide significant input for virtual modeling and simulations. It also provides a common design database for integrated design developments. Computer-Aided Engineering can provide system requirements and performance analysis in support of trade studies, analysis related to the eight primary functions, and cost analyses. Computer-Aided Systems Engineering can provide automation of technical management analyses and documentation.

Modeling

Modeling techniques allow the physical product to be visualized and evaluated prior to design decisions. Models allow optimization of hardware and software parameters, permit performance predictions to be made, allow operational sequences to be derived, and permit optimum allocation of functional and performance requirements among the system elements. The traditional logical prototyping used in Design Synthesis is the Schematic Block Diagram.

7: Verification

7.1 GENERAL

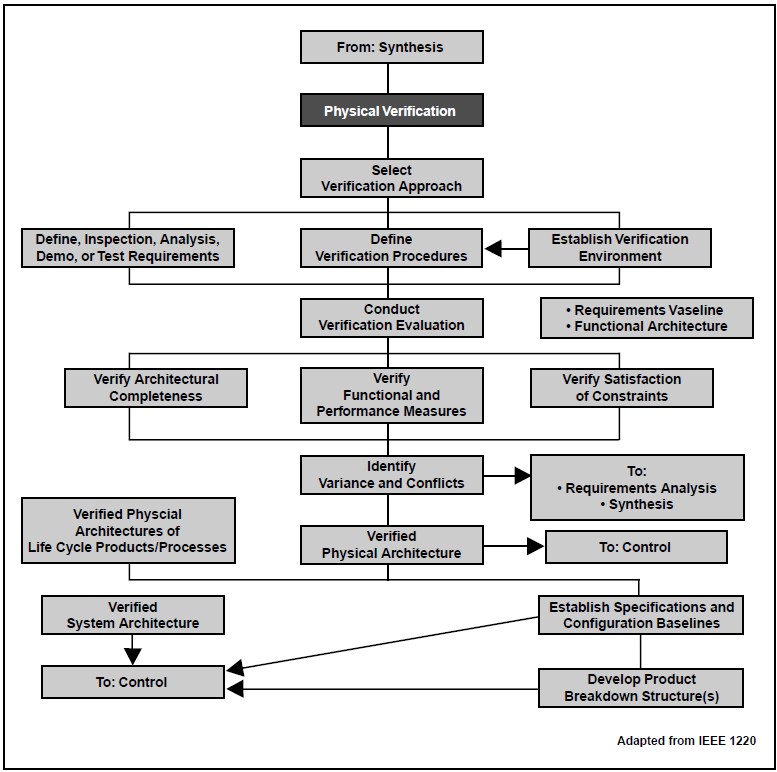

The Verification process confirms that Design Synthesis has resulted in a physical architecture that satisfies the system requirements. Verification rep-resents the intersection of systems engineering and test and evaluation.

Verification Objectives